Tire forming machine tire-cord connector pressing-closing device

A technology for laminating device and tire cord, which is applied in the field of rolling or pressing tire layers in the tire manufacturing process, can solve the problems of inconvenient use, poor applicability and high manufacturing cost, and achieves convenient use, low manufacturing cost and good applicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

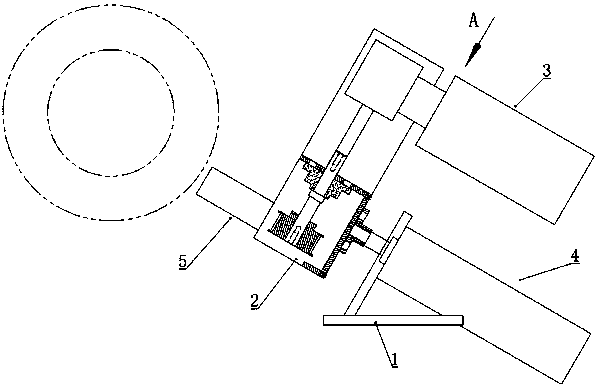

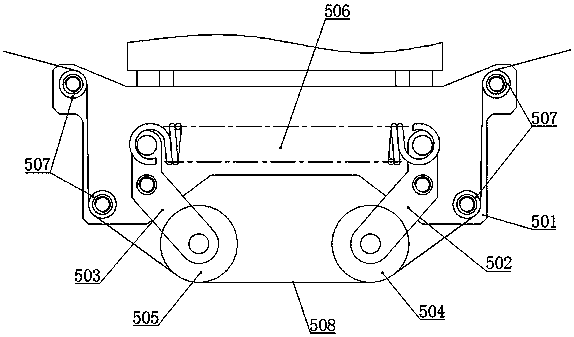

[0019] exist figure 1 , figure 2 Among them, a tire cord joint pressing device, which includes a frame 1, a beam 2, a driving mechanism 3, an adjusting mechanism 4 and a pressing mechanism 5. Wherein, the driving mechanism 3 is arranged at one end of the beam 2 .

[0020] exist figure 2 Among them, in this embodiment, the adjustment mechanism 4 includes a first adjustment cylinder 401 and a second adjustment cylinder 402 arranged at intervals, and the cylinder bodies of the first adjustment cylinder 401 and the second adjustment cylinder 402 are respectively fixed on the frame 1, and the second The piston rods of the first adjusting cylinder 401 and the second adjusting cylinder 402 are respectively fixed on the two ends of the beam 2, the first adjusting cylinder 401 and the second adjusting cylinder 402 work together to drive the beam 2 to approach or move away from the frame 1, and then adjust the beam The distance between the pressing mechanism 5 on the 2 and the fram...

Embodiment 2

[0026] exist Figure 4 In, the structure of another embodiment of the present invention is given.

[0027] exist Figure 4 Among them, a tire cord joint pressing device, which includes a frame 1, a beam 2, a driving mechanism 3, an adjusting mechanism 4 and a pressing mechanism 5.

[0028] In this embodiment, the structure and parts used of the frame 1, beam 2, adjustment mechanism 4 and pressing mechanism 5 are the same as those in Embodiment 1, and will not be described further here.

[0029] It differs from Example 1 in that: as Figure 4 As shown, in this embodiment, the driving mechanism 3 includes a driving motor 301 , a screw rod 305 and a nut 306 . Wherein, one end of the screw mandrel 305 is connected with the output shaft of the drive motor 301, and the other end of the screw mandrel 305 is rotatably supported on the end of the beam 2 away from the drive motor 301, and the nut 306 is threadedly fitted on the screw mandrel 305. The pressing seat 501 of the pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com