Stainless steel pot

A stainless steel pot and stainless steel technology, applied in the direction of pressure cooker, cooking utensil cover, cooking utensil structure, etc., can solve the problems of inconvenient operation, finger burns, pot lid scald, etc., achieve simple structure, ensure hygienic use, and improve heat utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

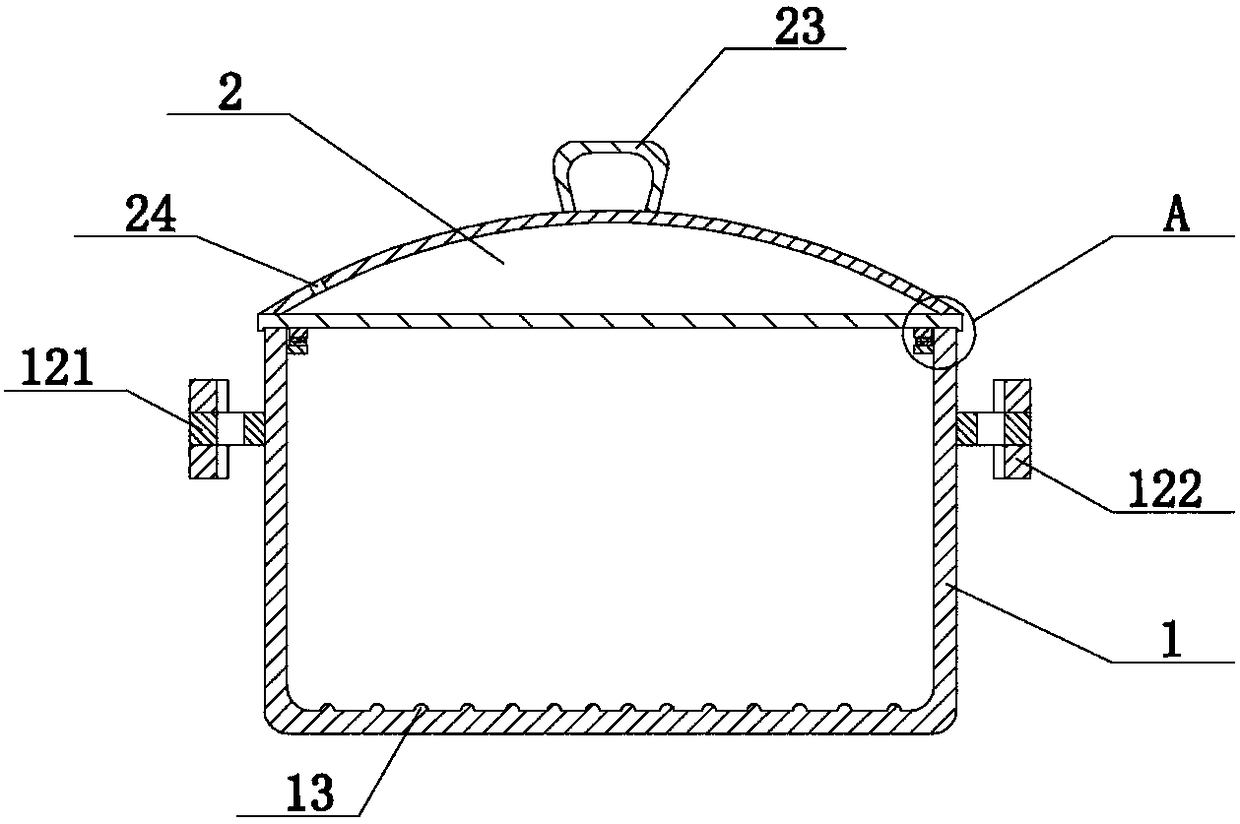

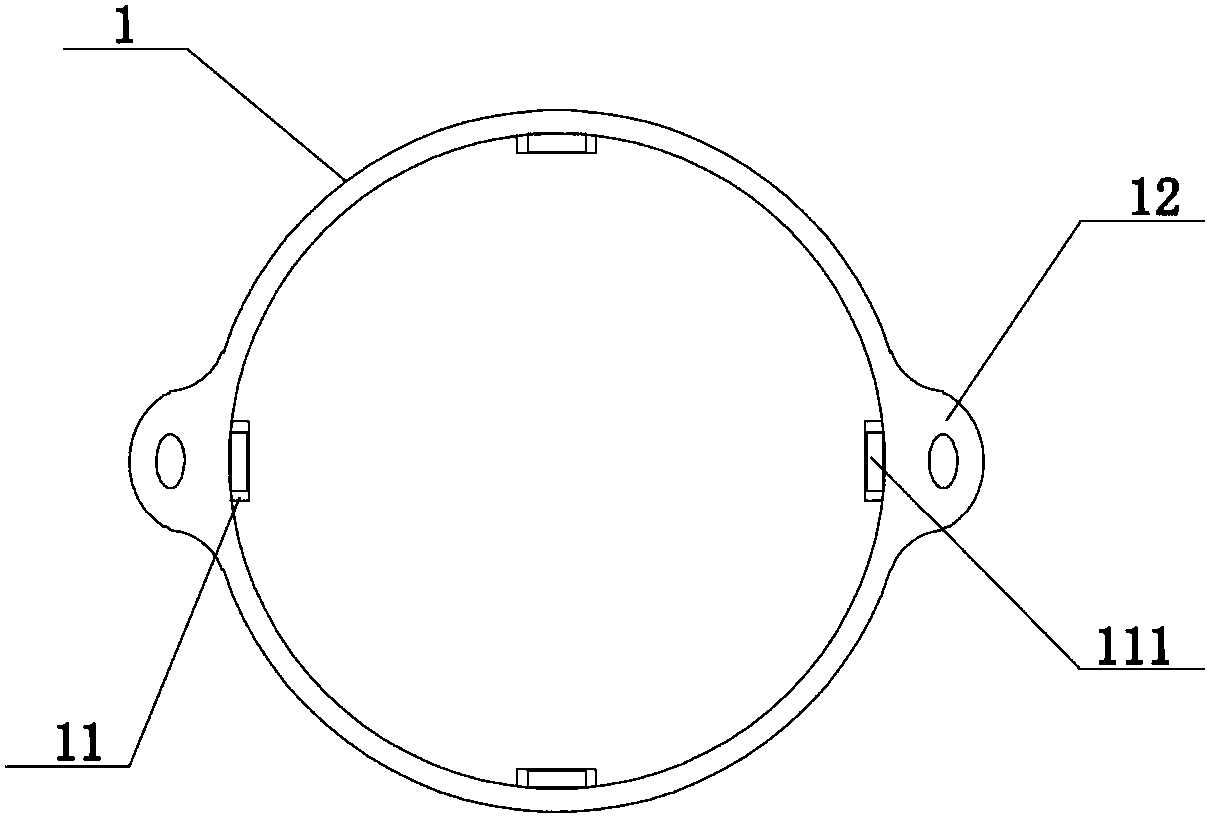

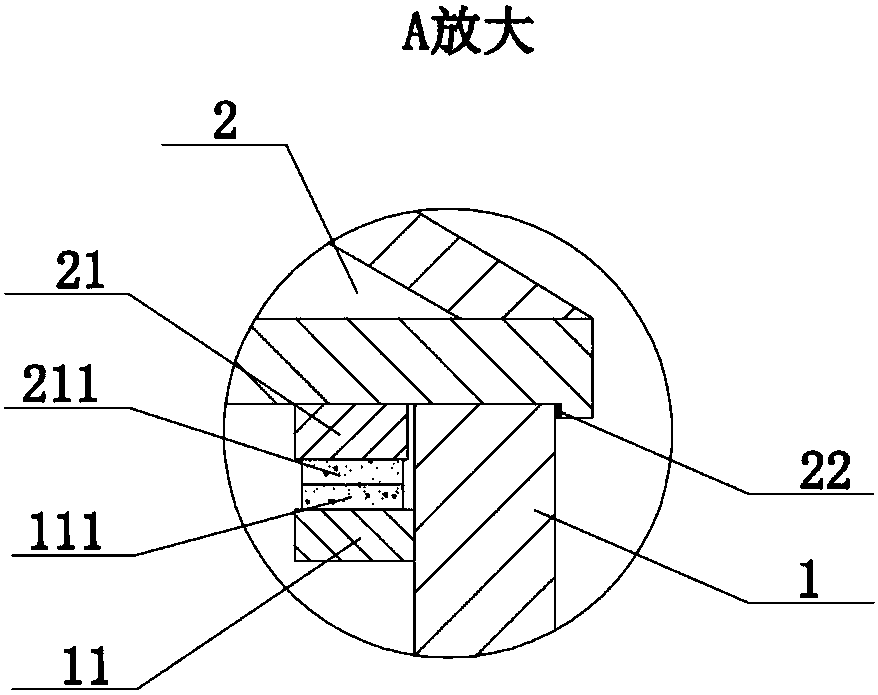

[0020] see Figure 1-Figure 3 As shown, the technical solution adopted in this specific embodiment is: it comprises a stainless steel pot body 1 and a stainless steel pot cover 2 arranged at the opening of the upper end of the stainless steel pot body 1, and the inner wall at the opening of the upper end of the stainless steel pot body 1 is evenly arranged in a circular shape. There are a plurality of first bosses 11, and a first magnet 111 is arranged on the first boss 11, and a plurality of second bosses 21 are evenly arranged in a ring on the inner wall of the lower opening of the stainless steel pot cover 2, so that The second boss 21 is provided with a second magnet 211 , the first boss 11 cooperates with the second boss 21 , and the first magnet 111 is connected with the second magnet 211 by suction.

[0021] Four of the first bosses 11 and the second bosses 21 are evenly arranged in an annular shape. The first boss 11 is designed to match the second boss 21 on the stai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com