Airport baggage matching inspection equipment and its usage method

A matching check and luggage technology, applied to computer components, instruments, induction record carriers, etc., can solve problems such as error-prone, achieve the effects of eliminating mistakes, convenient assembly and disassembly, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

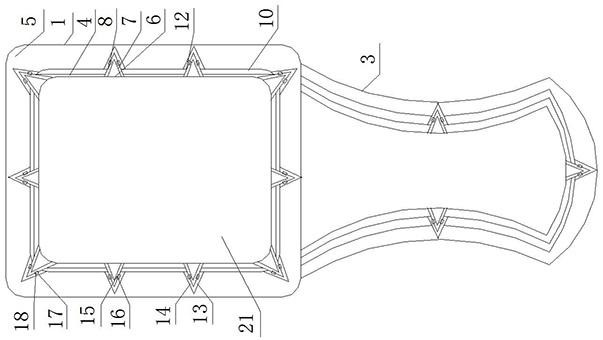

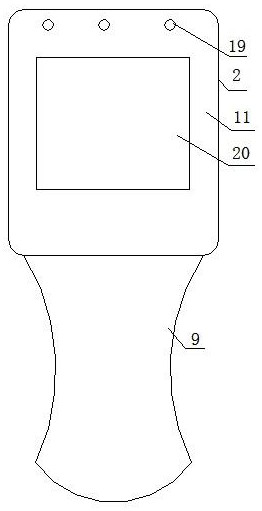

[0033] An airport baggage matching inspection device, which consists of: a base plate 1, an upper cover 2, the base plate is fixedly connected with a hand-held base plate 3, and the edges of the base plate and the hand-held base plate are connected with fixed insert rings 4, The edges of the bottom plate and the hand-held bottom plate extend out of the outside of the fixed insert ring to form the bottom outer edge 5, and the fixed insert ring has a group of fractures 6, and one end of the fracture is connected to the elastic oblique plate 7, the other end of the fracture is connected to the elastic side slant plate 8, the elastic slant plate and the elastic side slant plate form a triangular insert, the bottom of the triangular insert is connected to the outer edge of the bottom, The upper cover is connected with the handle upper cover 9, and the edges of the upper cover and the handle upper cover are connected with the insert ring 10, and the edges of the upper cover and the h...

Embodiment 2

[0035] In the airport baggage matching inspection device described in Embodiment 1, the elastic sloping plate and the elastic side sloping plate are both provided with inner grooves 15, and the inner grooves are connected to the inner magnetic sheet 16, and the swash plate and the Each of the side slanting plates is provided with an outer slot 17, and the outer slot is connected with an outer magnetic sheet 18. When the triangular plug is inserted into the triangular socket, the inner magnetic sheet is attracted to the outer magnetic sheet. disk.

[0036] The inner magnetic sheet is attracted to the outer magnetic sheet to further fix the bottom plate and the upper cover. It does not need to be fixed with screws. The assembly speed is fast and firm. It is also easy to disassemble and does not require auxiliary tools. Even if it is often disassembled, it will not damage the triangle. Plug-in and triangular socket, long service life.

Embodiment 3

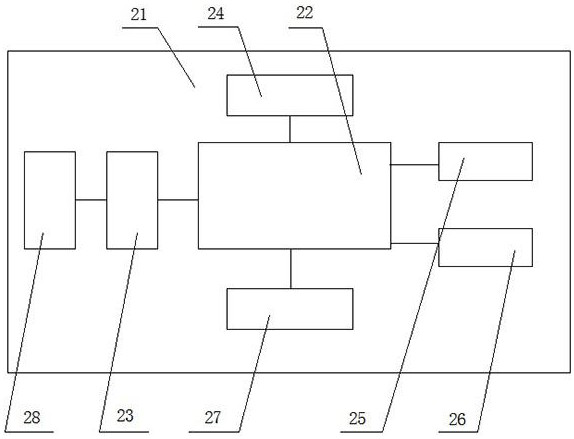

[0038] In the airport baggage matching inspection device described in Embodiment 1, the base plate is connected to the control board 21, and the control board is provided with a main control circuit, and the main control circuit includes a chip U1 and a part number 22. The chip U1 is connected to a charging circuit 23 , a keyboard input circuit 24 , an alarm circuit 25 , a scanning circuit 26 , and a display circuit 27 , and the charging circuit is connected to a power supply circuit 28 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com