Glass deep processing connection line control method

A glass deep processing and control method technology, applied in the direction of comprehensive factory control, glass manufacturing equipment, comprehensive factory control, etc., can solve the problems of multiple manpower and material resources, the influence of deep processing connection, and the decline in the qualified rate of glass products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

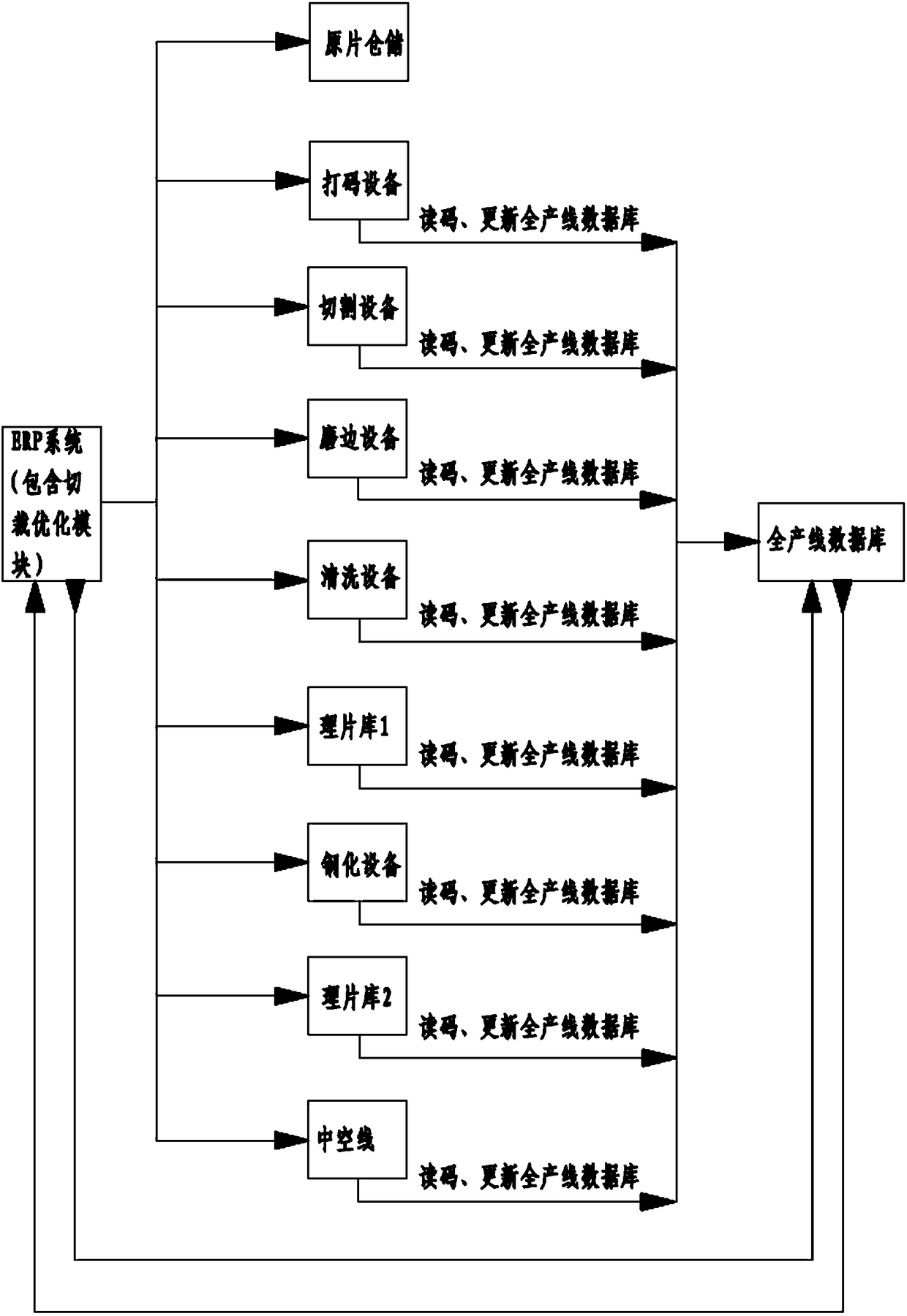

[0024] Such as figure 1 As shown, the glass deep processing production line in this embodiment includes: original sheet storage, coding equipment, cutting equipment, edging equipment, cleaning equipment, sorting warehouse 1, tempering equipment, sorting warehouse 2 and hollow production equipment (hollow line ).

[0025] The glass deep processing connection control method in this embodiment is:

[0026] After the customer receives the order, enter the order into the ERP system.

[0027] The cutting optimization module in the ERP system performs cutting optimization according to the inventory information of the existing original film storage, and obtains cutting optimization information.

[0028] According to the cutting optimization information, the ERP system sends a picking instruction to the picking mechanism of the original film storage, which includes information such as the type and quantity of the picking piece. The control system of the film taking mechanism is also...

Embodiment 2

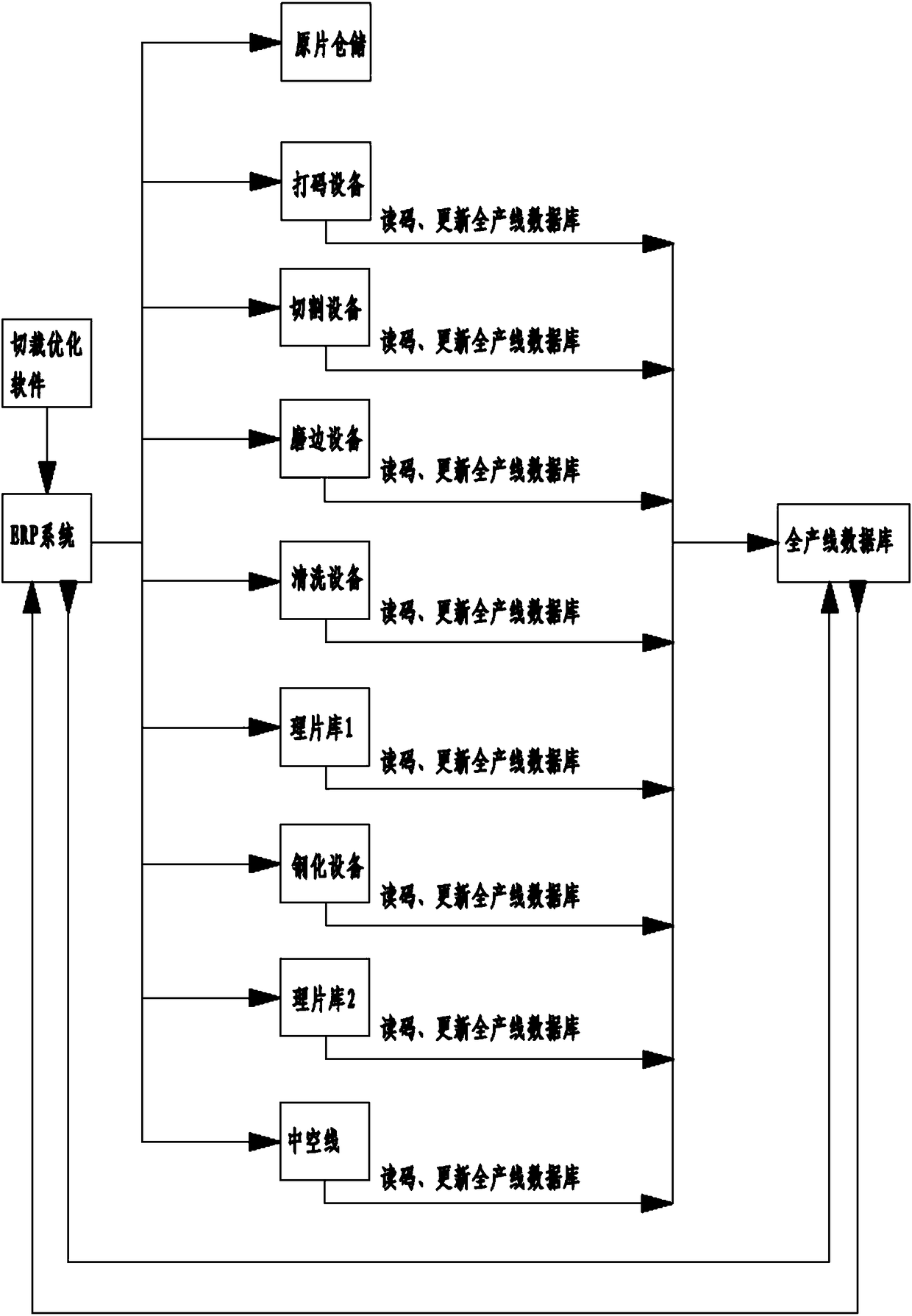

[0050] The difference between this embodiment and Embodiment 1 is that the cutting optimization module is no longer integrated in the ERP system, but as follows figure 2 As shown, the cutting optimization software performs cutting optimization according to the inventory information of the existing original film storage, and obtains the cutting optimization information, and the ERP system can receive the cutting optimization information of the cutting optimization software.

Embodiment 3

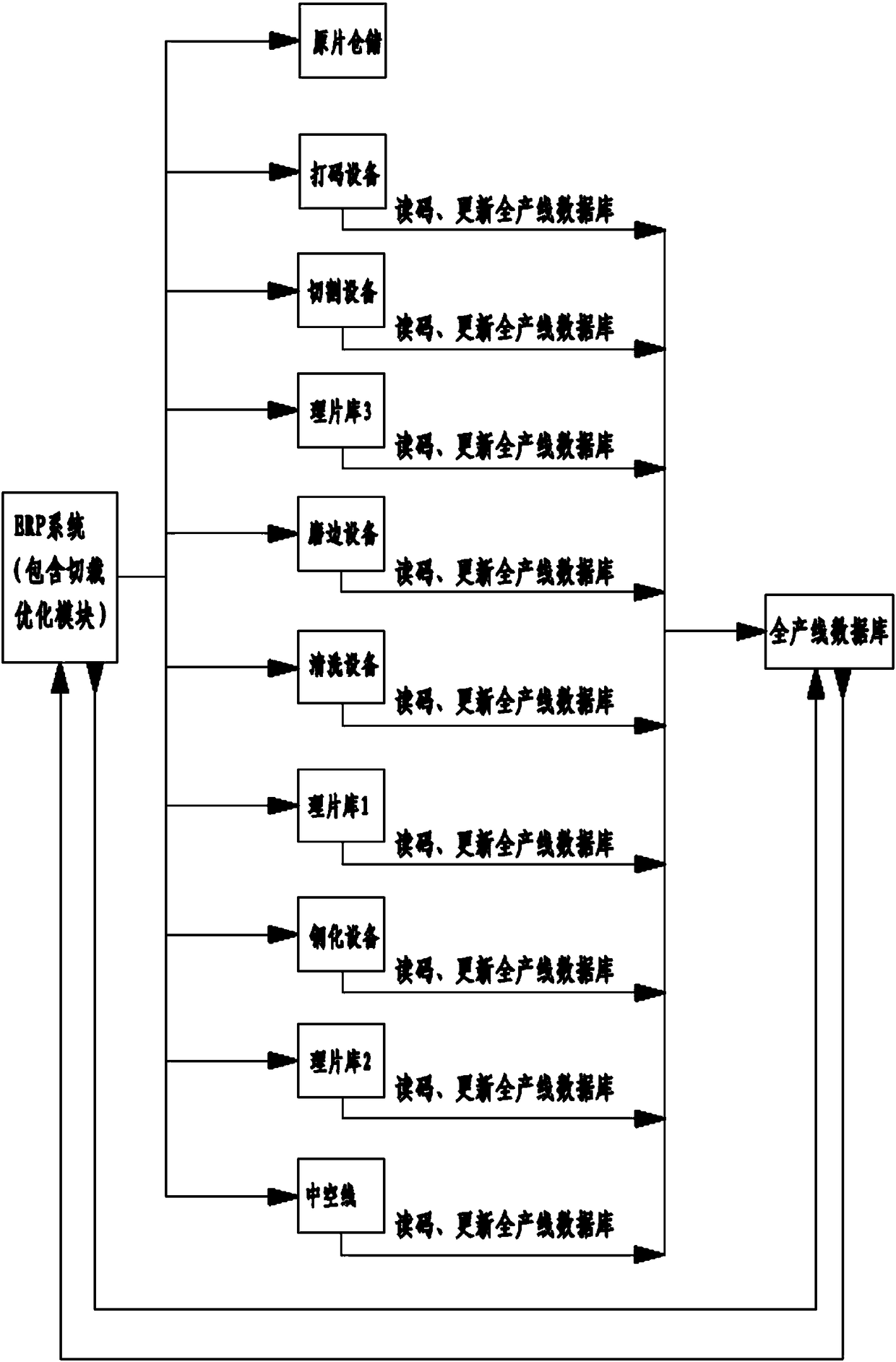

[0052] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the glass plate enters the film storage 3 after coming out from the cutting equipment (such as image 3 As shown), the cardboard library 3 can play the role of caching glass plates and sorting and sorting the glass plates. After the glass plates come out of the cardboard storehouse 3, the identification code information data updates the SQL database, and the ERP system updates the SQL database according to the data update and loss. , Automatically generate patch information, through the cutting optimization information of the cutting optimization module in the ERP system, automatically code, cut, and provide patches.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com