Material temperature measuring device for soaking furnace

A technology of soaking furnace and material temperature, which is applied in the direction of thermometers, thermometers, and measuring devices that use electrical/magnetic components directly sensitive to heat. Achieve the effect of isolating heat loss, improving accuracy and reducing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

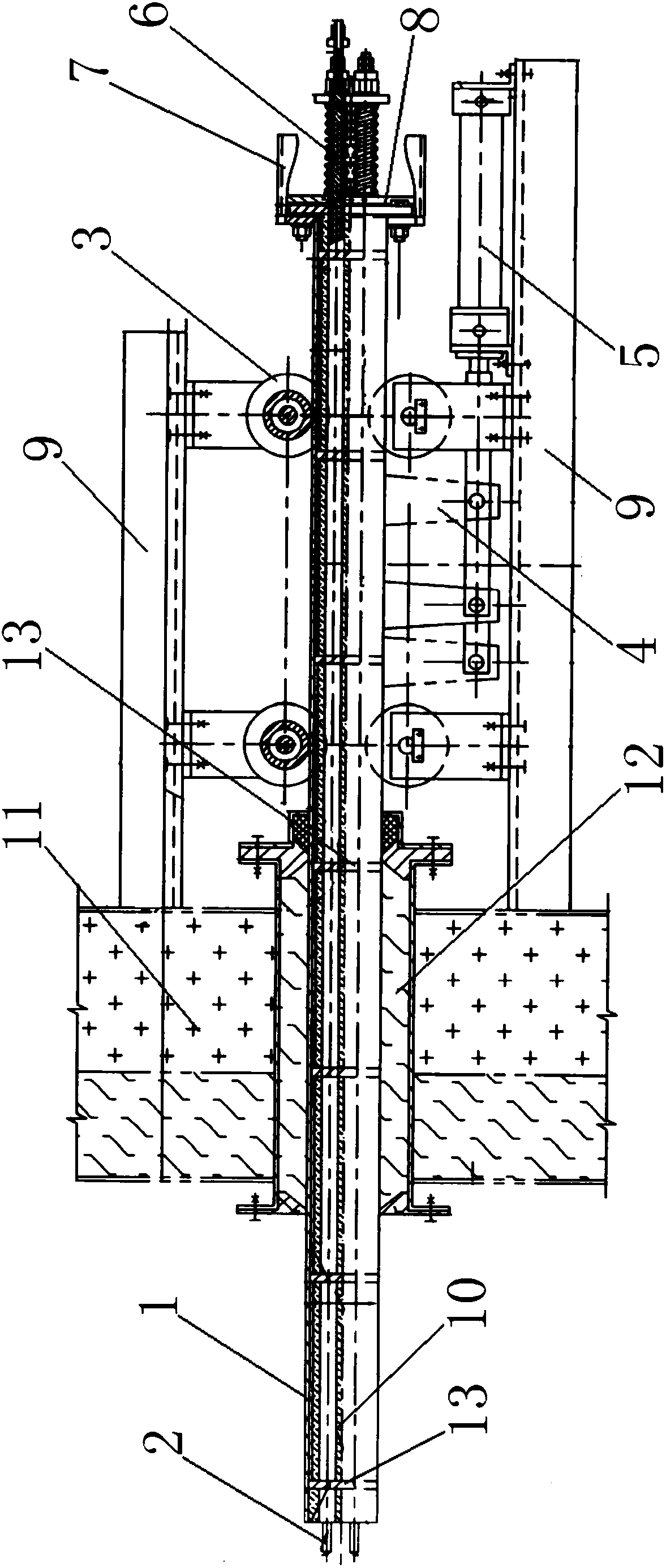

[0029] In order to achieve the purpose of the present invention, a material temperature measuring device for a soaking furnace includes: a cylinder body 1, the cylinder body 1 passes through the furnace wall 11, four metal rods 2 are pierced inside the cylinder body 1, and the four metal rods 2 Two of them are nickel-chromium alloy rods, and the other two are nickel-silicon alloy rods; the guide mechanism, the guide wheel 3 is fixed on the frame 9, and the guide wheel 3 is in contact with the outer surface of the cylinder 1; the driving mechanism, the drive cylinder 1 Axial reciprocating motion.

[0030] There are four guide wheels 3, and four guide wheels 3 are divided into two groups, each group of two guide wheels 3, and the line of the same group of guide wheels 3 is parallel to the axis of cylinder body 1 itself.

[0031] The cylindrical body 1 advance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com