Reinforcing structure for alleviating tramcar trackside asphalt pavement cracking

A technology for asphalt pavement and reinforcement structure, applied in the direction of roads, roads, special pavements, etc., can solve problems such as deformation of fastener covers, uncoordinated deformation of asphalt surface layers, loose asphalt concrete peeling, etc., achieve small deformation, improve cracking effects, The effect of bearing a small load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

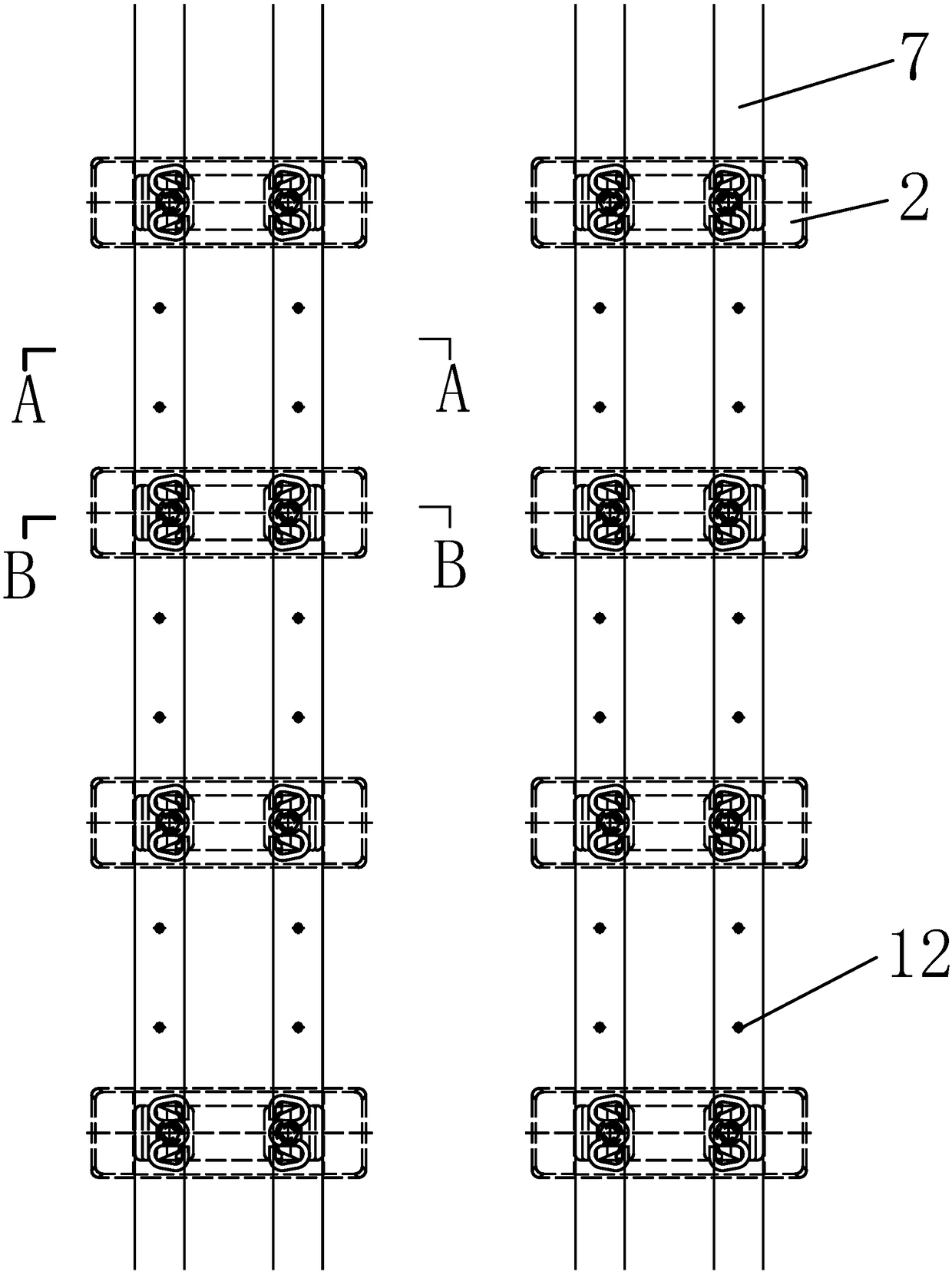

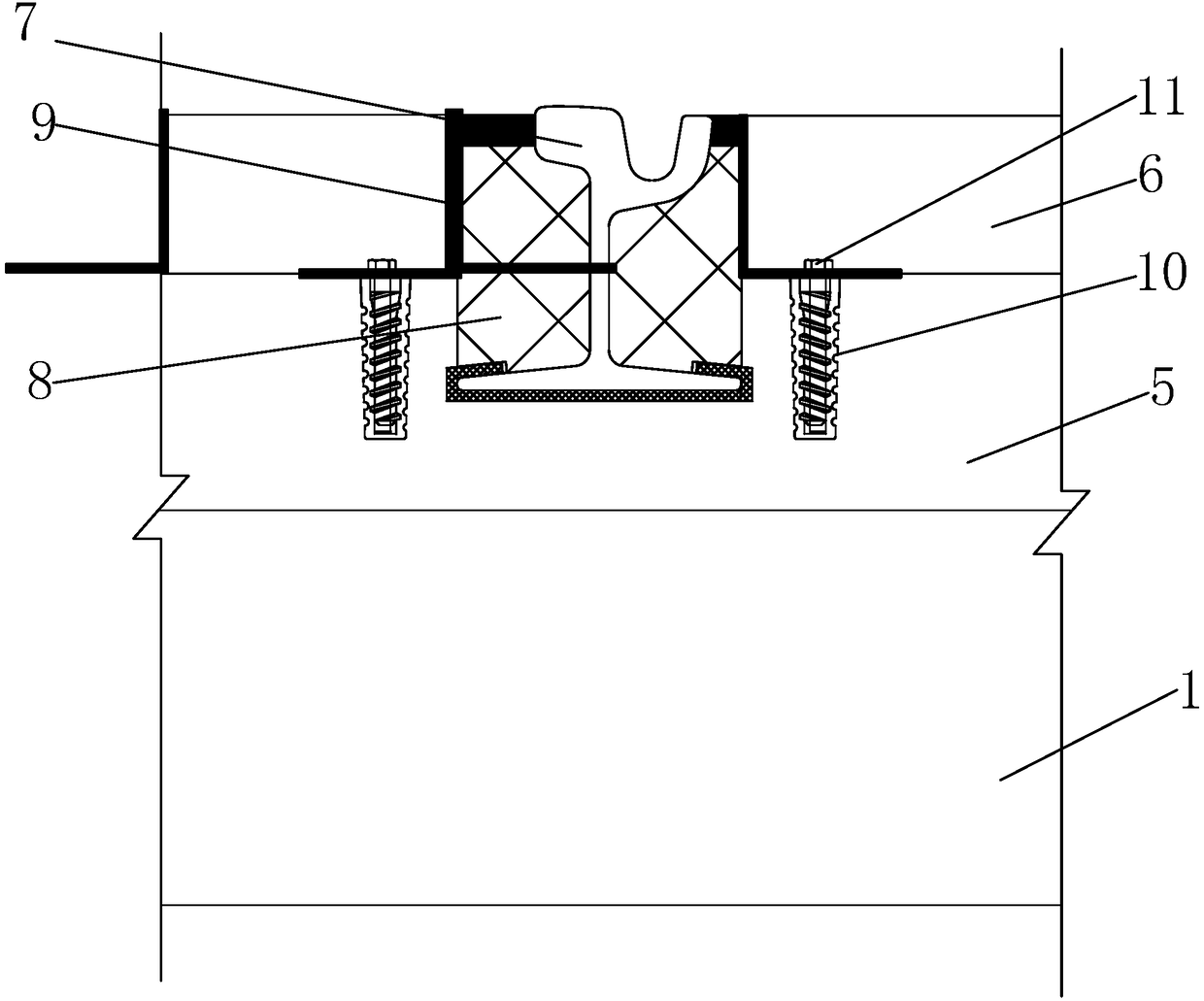

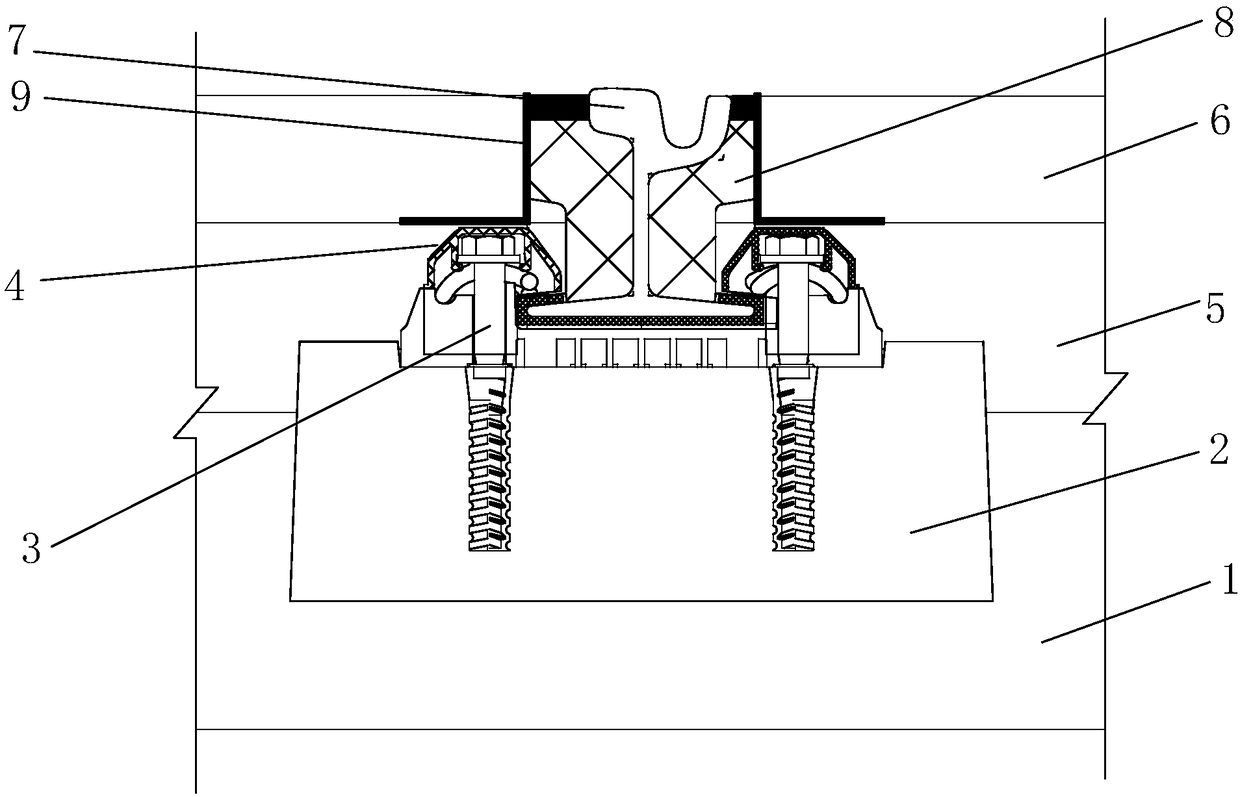

[0023] refer to figure 1 , figure 2 and image 3 , the present invention includes sleepers 2 arranged at equal intervals on the ballast bed layer 1, and above the ballast bed layer 1, a concrete adjustment layer 5 and an asphalt pavement layer 6 are sequentially laid. The sleeper 2 is buried in the ballast bed layer 1, and a rail 7 is arranged on the sleeper 2, and the rail 7 is fixed on the sleeper 2 by a fastener 3, and a fastener cover 4 is arranged on the fastener 3. A flexible wrapping material 8 is arranged on the sleeper 2 and beside the rail 7 between the adjacent sleepers 2, and a transverse baffle 9 is arranged on the outside of the flexible wrapping material 8, and the transverse baffle 9 adopts an angle steel of L100×8mm, so The bottom surface of the angle steel is placed on the fastener cover 4 , the bottom surface of the angle steel replaces the guard plate to protect the fastener cover 4 , and the bottom surface of the transverse baffle 9 is placed on the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com