Detergent supply device and wash machine

A supply device and detergent technology, applied in washing devices, other washing machines, applications, etc., can solve problems such as insufficient dilution of liquid detergent, unsmooth siphoning, secondary pollution of clothes, etc., to achieve easy implementation and improvement, and save manufacturing Cost, the effect of enhancing the siphon power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

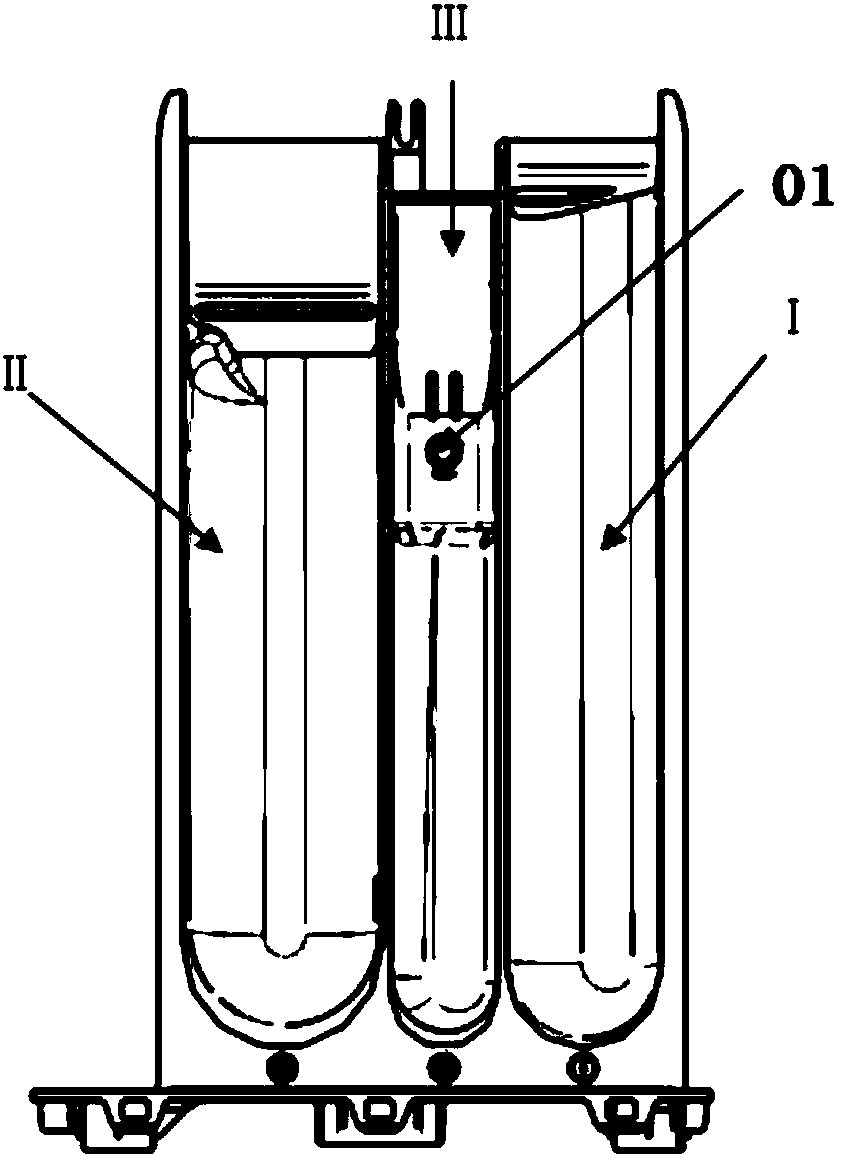

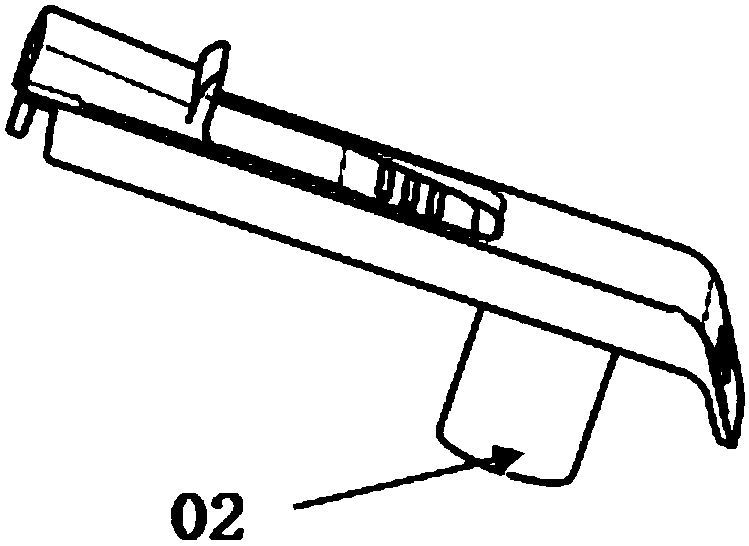

[0058] Figure 5 It is a schematic diagram of the dispenser structure of the detergent supply device of the present invention. The dispenser has three detergent or additive injection chambers, two of which are used to inject liquid detergent or additives, including a siphon structure, and one of the chambers is used for Put softener, the siphon structure of the chamber includes the siphon hole 01 arranged in the liquid detergent delivery chamber and the first siphon cap 03 covering the siphon hole 01, the first siphon cap 03 has the common structure of the prior art siphon cap , the siphon hole 01 is assembled with the first siphon cap 03 and forms a flow channel, and the flow channel communicates with the siphon hole 01; the other chamber is a bleach injection chamber 4 for injecting bleach (of course, it can also be used according to actual needs It is set to put in other liquid detergents or additives, which is not as a limitation to the technical solution), the siphon stru...

Embodiment 2

[0084] The main difference between this embodiment and Embodiment 1 is that the siphon structures in the two chambers for putting liquid detergent or additives all have the structural characteristics described in the present invention, that is, the first siphon cap 03, the second siphon cap 04 and the siphon hole 01 are respectively assembled behind the parts that increase the flow rate of the liquid.

[0085] The rear refers to the flow direction of the liquid in the liquid detergent injection chamber as a reference. The liquid first passes through the parts that increase the liquid flow rate, and then passes through the assembly of the siphon cap and the siphon hole. The parts that increase the liquid flow rate are relatively opposite to the siphon cap and the siphon hole. The assembly point is the rear.

[0086] For other azimuth representations, refer to the above explanations.

[0087] combine Figure 6 , the direction of liquid flow is from A→B, A is the liquid inlet e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com