Fermentation culture medium for increasing ganoderic acid A in liquid fermented ganoderma mycelium and fermentation method

A technology of Ganoderma lucidum mycelium and fermentation medium, which is applied in the field of edible and medicinal fungus production technology, which can solve the problems of autolysis of mycelium, decrease in output, increase in cost, etc., and achieve the effect of realizing batch production and simple and controllable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

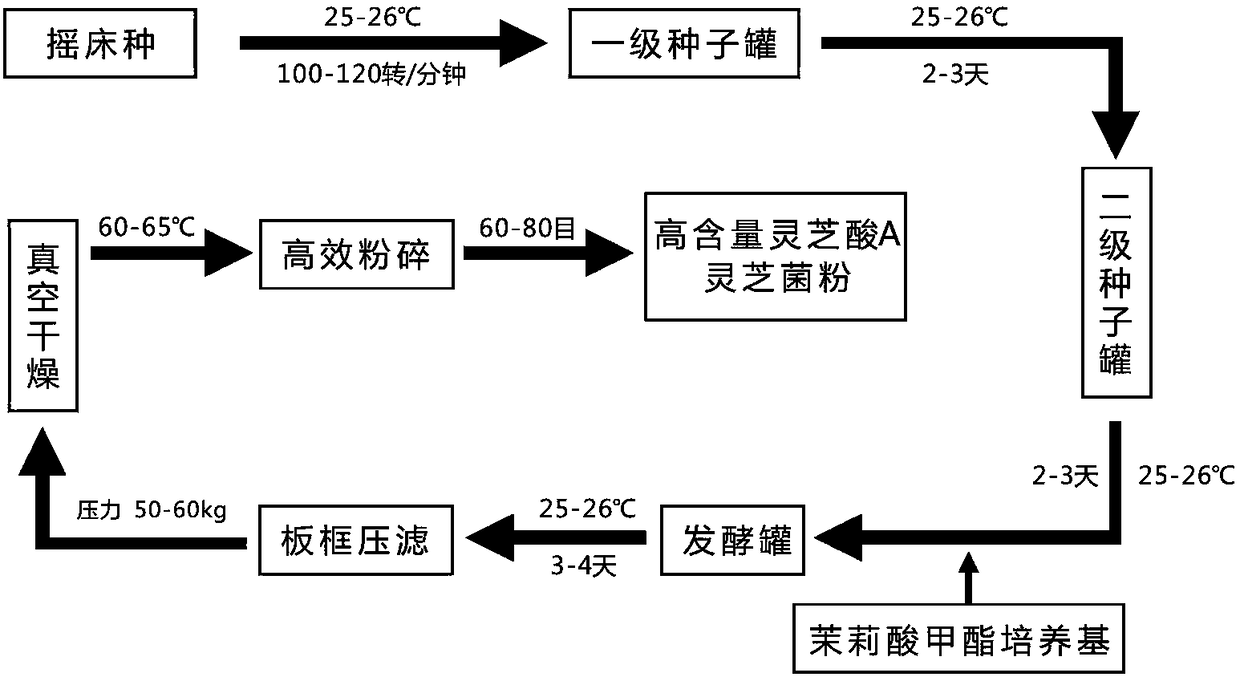

Method used

Image

Examples

Embodiment 1

[0038] 1), select the ganoderma lucidum mycelium strain:

[0039] 2) Shaker seed: keep the temperature at 25°C, dilute the strain into 300ml liquid culture medium with about 1 square centimeter plate with culture medium, put it on the shaker, and stir for 3 days, control the stirring speed to 100 rpm / min; the liquid medium includes 2% corn flour, 1% soybean flour, 1% glucose, 1% yeast extract, 0.1% potassium dihydrogen phosphate, 0.05% magnesium sulfate, 50ppm vitamin B1, and the balance is water.

[0040] 3), one-level amplification: keep the temperature at 25°C, inhale the culture medium stirred in step 2) into a 300L seed tank with liquid culture medium under negative pressure, and cultivate for 2 days;

[0041] 4), two-stage amplification: keep the temperature at 25°C, suck the stirred liquid culture medium in step 3) into a 1.5-ton seed tank with liquid culture medium under negative pressure, and cultivate it for 2 days to obtain Ganoderma lucidum hyphae body seed fluid...

Embodiment 2

[0048] 1), select the ganoderma lucidum mycelium strain:

[0049] 2) Shaking table seed: keep the temperature at 26°C, dilute the strain into 150ml liquid medium with about 1 square centimeter plate with culture medium, put it on the shaker, and stir for 4 days, control the stirring speed to 120 rpm / min; the liquid medium includes 4% of corn flour, 2% of soybean flour, 1% to 3% of glucose, 1% of yeast extract, 0.5% of potassium dihydrogen phosphate, 0.1% of magnesium sulfate, and vitamin B1 in terms of mass percentage. 100ppm, the balance is water.

[0050] 3), one-level amplification: keep the temperature at 26°C, suck the culture medium stirred in step 2) into a 300L seed tank with liquid culture medium under negative pressure, and cultivate for 3 days;

[0051] 4), two-stage amplification: keep the temperature at 26°C, suck the stirred liquid culture medium in step 3) into a 1.5-ton seed tank with liquid culture medium under negative pressure, cultivate for 3 days, and ob...

Embodiment 3

[0058] 1), select the ganoderma lucidum mycelium strain:

[0059] 2) Shaker seed: keep the temperature at 26°C, dilute the strain into 200ml liquid medium with about 1 square centimeter plate with culture medium, put it on the shaker, and stir for 3 days, control the stirring speed to 110 rpm / min; the liquid medium includes 3% corn flour, 2% soybean flour, 2% glucose, 1% yeast extract, 0.3% potassium dihydrogen phosphate, 0.08% magnesium sulfate, 75ppm vitamin B1, and The amount is water.

[0060] 3), one-level amplification: keep the temperature at 25°C, inhale the culture medium stirred in step 2) into a 300L seed tank with liquid culture medium under negative pressure, and cultivate for 2 days;

[0061] 4), two-stage amplification: keep the temperature at 25°C, suck the stirred liquid culture medium in step 3) into a 1.5-ton seed tank with liquid culture medium under negative pressure, and cultivate it for 2 days to obtain Ganoderma lucidum hyphae body seed fluid;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com