Flame-retardant aging-resistant cable material and preparation method thereof

A cable material and anti-aging technology, applied in plastic/resin/wax insulators, organic insulators, etc., can solve a lot of smoke and irritating toxic gases, affect cable insulation, endanger human health and other problems, and achieve good market application prospects , increase oxidation resistance and stability, good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

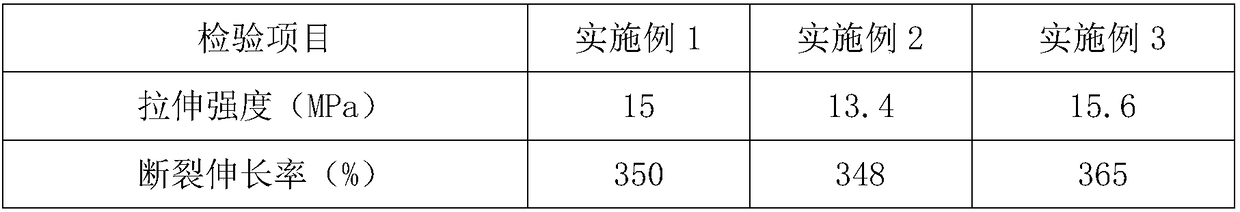

Examples

Embodiment 1

[0031] A flame-retardant and aging-resistant cable material, comprising the following raw materials in parts by weight:

[0032] 30 parts of epoxy resin, 20 parts of polyurethane rubber, 23 parts of silicone grease, 18 parts of attapulgite, 15 parts of ceramic fiber, 20 parts of calcium silicate, 8 parts of medical stone, 18 parts of nano silicon dioxide, nano titanium nitride 8 parts, 15 parts of magnesium hydroxide, 15 parts of aluminum hydroxide, 5 parts of phosphite, 8 parts of octadecyl alcohol ester, 4 parts of citric acid, 7 parts of sodium citrate, 5 parts of silane coupling agent, lubricating 2 parts of curing agent, 1.8 parts of curing agent, 3.2 parts of flame retardant, 1.2 parts of initiator, and 2.4 parts of ultraviolet absorber.

[0033] The silane coupling agent is composed of methyltriethoxysilane and bis(γ-triethoxysilylpropyl)-tetrasulfide in a mass ratio of 2:1.

[0034] The lubricant is composed of magnesium stearate, graphite and molybdenum disulfide in ...

Embodiment 2

[0046] A flame-retardant and aging-resistant cable material, comprising the following raw materials in parts by weight:

[0047] 45 parts of epoxy resin, 32 parts of polyurethane rubber, 35 parts of silicone grease, 26 parts of attapulgite, 22 parts of ceramic fiber, 28 parts of calcium silicate, 16 parts of medical stone, 26 parts of nano silicon dioxide, nano titanium nitride 18 parts, 22 parts of magnesium hydroxide, 22 parts of aluminum hydroxide, 12 parts of phosphite, 13 parts of stearyl alcohol ester, 8 parts of citric acid, 10 parts of sodium citrate, 9 parts of silane coupling agent, lubricating 5 parts of curing agent, 3.6 parts of curing agent, 5.5 parts of flame retardant, 2.8 parts of initiator, and 3.8 parts of ultraviolet absorber.

[0048] The silane coupling agent is N-(β-aminoethyl)-γ-aminopropyltriethoxysilane and N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane according to the mass ratio of 1: 1 mix composition.

[0049] The lubricant is composed of magnesiu...

Embodiment 3

[0061] A flame-retardant and aging-resistant cable material, comprising the following raw materials in parts by weight:

[0062] 42 parts of epoxy resin, 28 parts of polyurethane rubber, 26 parts of silicone grease, 22 parts of attapulgite, 18 parts of ceramic fiber, 24 parts of calcium silicate, 10 parts of medical stone, 21 parts of nano silicon dioxide, nano titanium nitride 14 parts, 17 parts of magnesium hydroxide, 18 parts of aluminum hydroxide, 8 parts of phosphite, 10 parts of octadecyl alcohol ester, 5 parts of citric acid, 8 parts of sodium citrate, 8 parts of silane coupling agent, lubricating 3.6 parts of curing agent, 2.8 parts of curing agent, 4.2 parts of flame retardant, 2.1 parts of initiator, 3.2 parts of ultraviolet absorber.

[0063] The silane coupling agent is bis(γ-triethoxysilylpropyl)-tetrasulfide.

[0064] The lubricant is composed of magnesium stearate, graphite and molybdenum disulfide in a mass ratio of 5:2:1.

[0065] The curing agent is compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com