Polycarboxylic acid and its use in cement

A technology of polycarboxylic acid and sulphoaluminate cement, which is applied in the field of polycarboxylic acid and its application in cement, and can solve the problem of small initial fluidity or slump, large dosage, poor flow retention or slump retention problems such as prolonging the maintenance of slump and fluidity, meeting engineering requirements, and improving the effect of water reduction and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

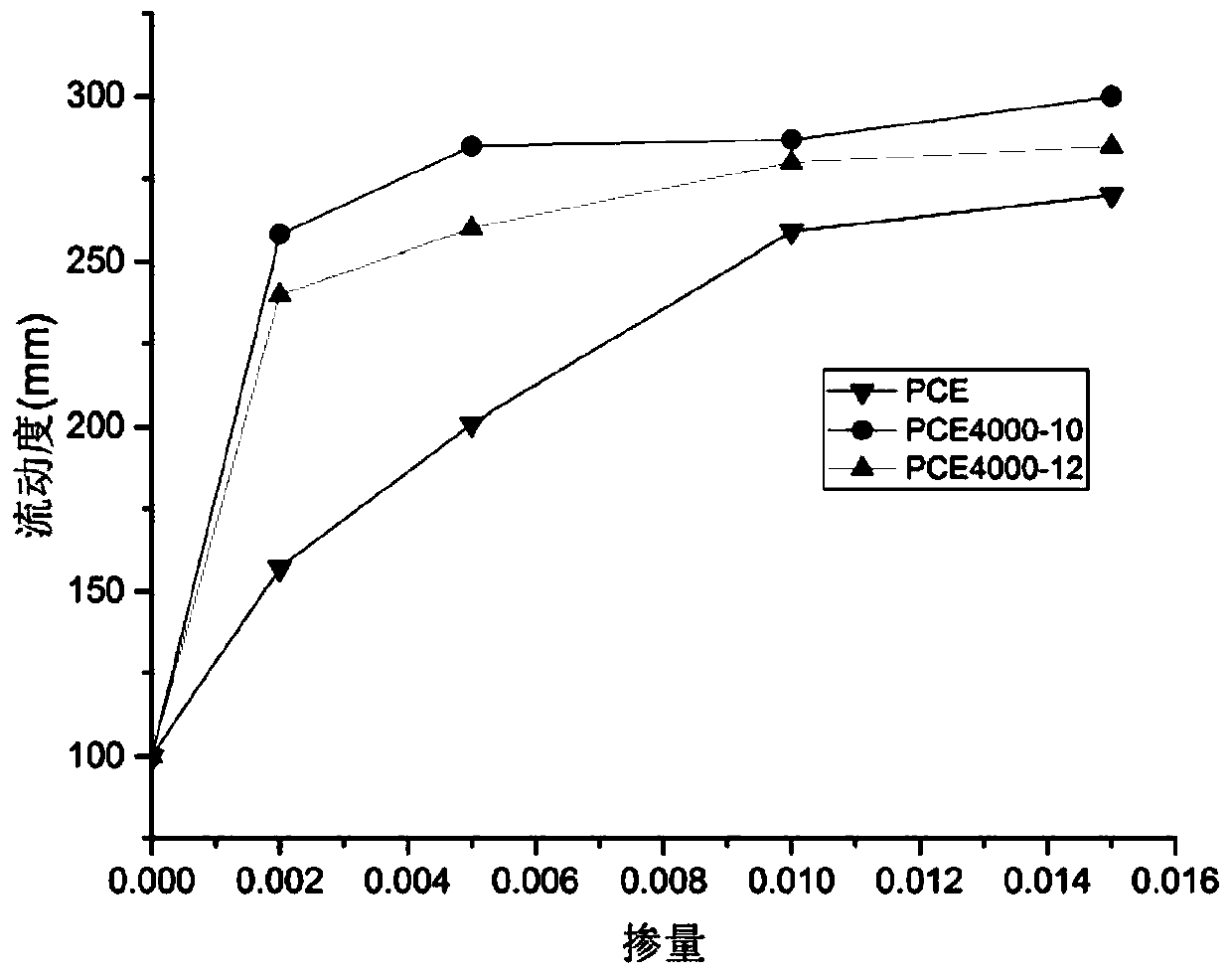

[0058] Synthesis of PCE4000-10: Weigh 82g of water and 50g of HPEG, dissolve and mix evenly, pour into a three-necked flask in a constant temperature water bath, stir at a constant speed of 150rpm with the stirring paddle and raise the temperature to 65°C, weigh 0.37g of HPEG with a mass concentration of 30% 2 o 2 Added to the three-necked flask. Mix 9g AA and 24g water uniformly to prepare dropwise A, and mix 0.204g3-MPA, 0.125gVc and 25g water uniformly to prepare dropwise B. Drop A and drop B are added dropwise into the three-necked flask through a peristaltic pump at a constant speed. The drop time for A is 3 hours, and the time for B drop is 3.5 hours. After the dropwise addition is completed, keep warm for 1 h. After the reaction, the actual solid content test was carried out, and the test result was 29.8%.

Embodiment 2

[0060] Synthesis of PCE4000-12: Weigh 82g of water and 50g of HPEG, dissolve and mix evenly, pour into a three-neck flask in a constant temperature water bath, stir at a constant speed of 150rpm with the stirring paddle and raise the temperature to 65°C, weigh 0.37g of HPEG with a mass concentration of 30% 2 o 2 Added to the three-necked flask. Mix 10.8g AA and 24g water uniformly to prepare dropwise A, and mix 0.241g3-MPA, 0.147gVc and 25g water uniformly to prepare dropwise B. Drop A and drop B are added dropwise into the three-necked flask through a peristaltic pump at a constant speed. The drop time for A is 3 hours, and the time for B drop is 3.5 hours. After the dropwise addition is completed, keep warm for 1 h. After the reaction, the actual solid content test was carried out, and the test result was 28.9%.

Embodiment 3

[0062] Synthesis of PCE4000-16: Weigh 150g of water and 80g of HPEG, dissolve and mix evenly, pour into a three-neck flask in a constant temperature water bath, stir at a constant speed of 150rpm with the stirring paddle and heat up to 65°C, weigh 0.77g of HPEG with a mass concentration of 30% 2 o 2 Added to the three-necked flask. Mix 23.04g AA and 50g water uniformly to prepare dropwise A, and mix 0.505g3-MPA, 0.308gVc and 30g water uniformly to prepare dropwise B. Drop A and drop B are added dropwise into the three-necked flask through a peristaltic pump at a constant speed. The drop time for A is 3 hours, and the time for B drop is 3.5 hours. After the dropwise addition is completed, keep warm for 1 h. After the reaction, the actual solid content test was carried out, and the test result was 28.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com