Manufacturing method for autoclaved aerated concrete block

A concrete block, autoclaved gas filling technology, applied in the field of building materials, can solve the problems of reducing the adsorption effect of bamboo charcoal, the injury of block production workers and installation workers, and reducing radioactivity, so as to achieve the goal of not easy to breed bacteria, good bactericidal and antibacterial effects, Effect of improving indoor air environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

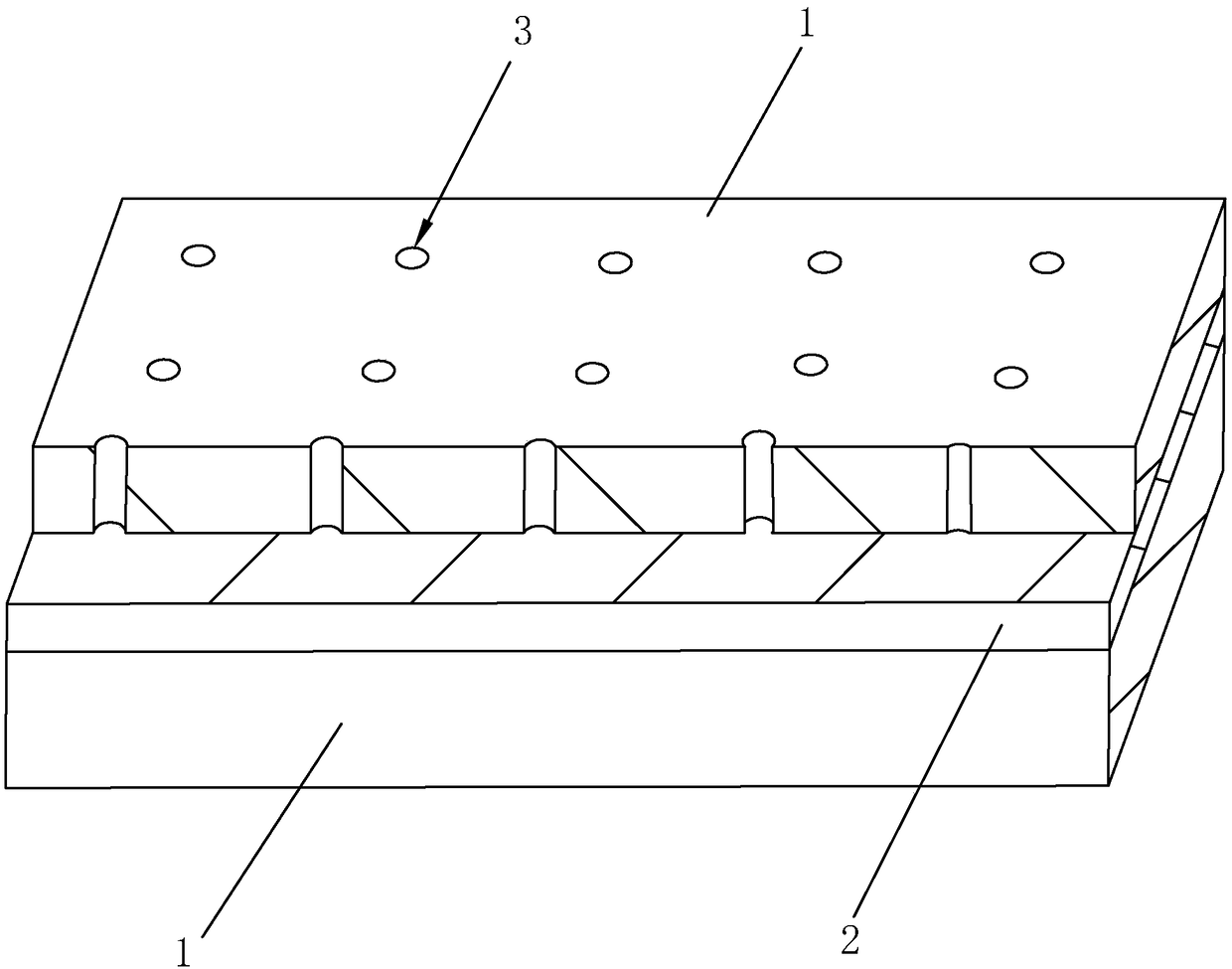

[0053] Embodiment 1: a kind of autoclaved aerated concrete block, such as figure 1 As shown, it includes two base layers 1 and an adsorption layer 2 arranged between the two base layers 1 . A base layer 1 is provided with a plurality of adsorption holes 3 , and the plurality of adsorption holes 3 communicate with the upper surface of the adsorption layer 2 and the base layer 1 . Base layer 1 includes lime, cement, 0.07 parts of foaming agent, 0.5 parts of polyacrylamide water retaining agent, foam stabilizer, 7 parts of vinylon fiber, 7 parts of mint, 7 parts of Senecio, 5 parts of tea, 5 parts of dried ginger, sand , desulfurized gypsum, 10 parts of ceramic waste residue and fly ash, the adsorption layer 2 includes 26 parts of formaldehyde purification adsorbent, 5 parts of tea leaves and 3 parts of vinylon fiber.

Embodiment 2

[0054] Embodiment 2: An autoclaved aerated concrete block. The difference between Embodiment 2 and Embodiment 1 is that the base layer 1 includes lime, cement, 0.07 parts of foaming agent, 0.6 parts of polyacrylamide water-retaining agent, stabilizer Foaming agent, 11 parts of vinylon fiber, 8 parts of mint, 8 parts of Senecio, 5.5 parts of tea, 6 parts of dried ginger, 10 parts of sand, desulfurized gypsum, ceramic waste residue and fly ash, adsorption layer 2 includes 33 parts of formaldehyde purification adsorbent , 7 parts of tea leaves and 3.5 parts of vinylon fiber.

Embodiment 3

[0055] Example 3: An autoclaved aerated concrete block. The difference between Example 3 and Example 1 is that the base layer 1 includes lime, cement, 0.07 parts of foaming agent, 0.7 part of polyacrylamide water-retaining agent, stabilizer Foaming agent, 15 parts of vinylon fiber, 9 parts of mint, 9 parts of Senecio, 6 parts of tea, 7 parts of dried ginger, 10 parts of sand, desulfurized gypsum, ceramic waste residue and fly ash, adsorption layer 2 includes 41 parts of formaldehyde purification adsorbent , 10 parts of tea leaves and 4 parts of vinylon fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com