Resource-recyclable zero-discharge treatment technology and device for desulfurization wastewater in power plant

A technology for desulfurization wastewater and resource recovery, which is applied in the direction of gaseous effluent wastewater treatment, dehydration/drying/thickened sludge treatment, water/sewage treatment, etc. High-level problems, to achieve the effect of reducing the burden and the risk of fouling, good capture and removal, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

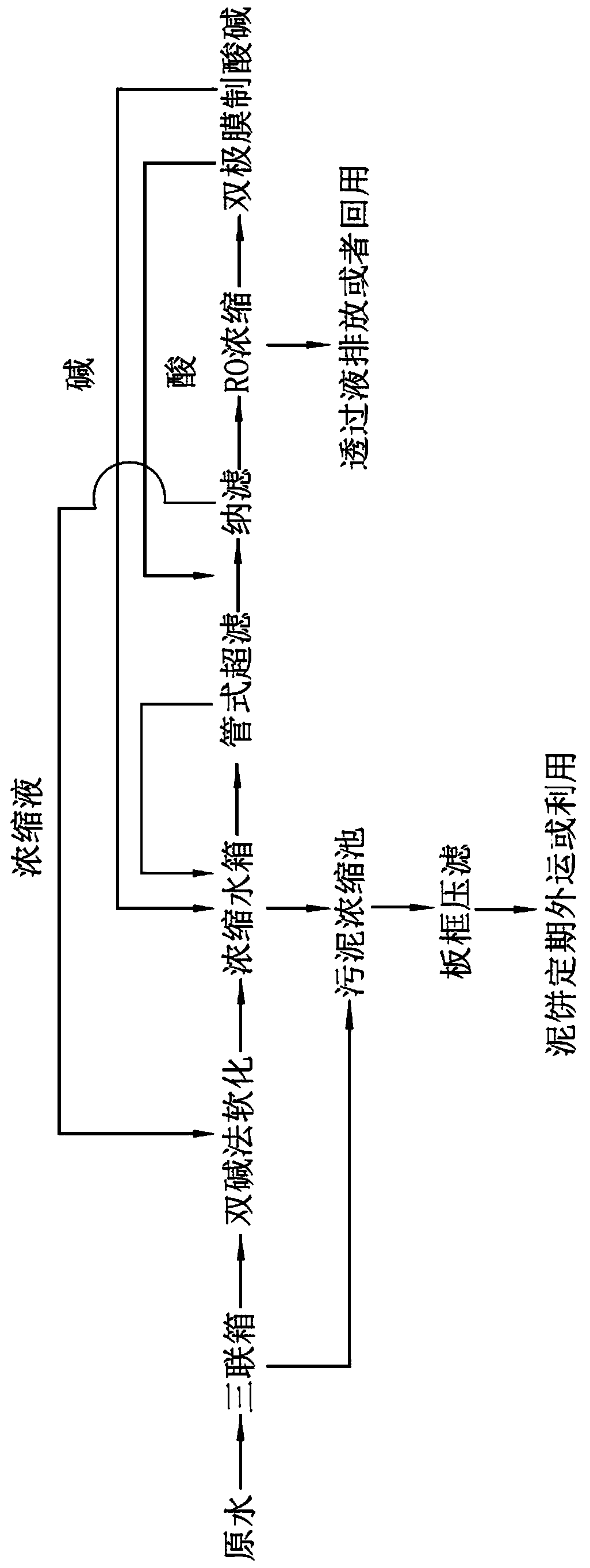

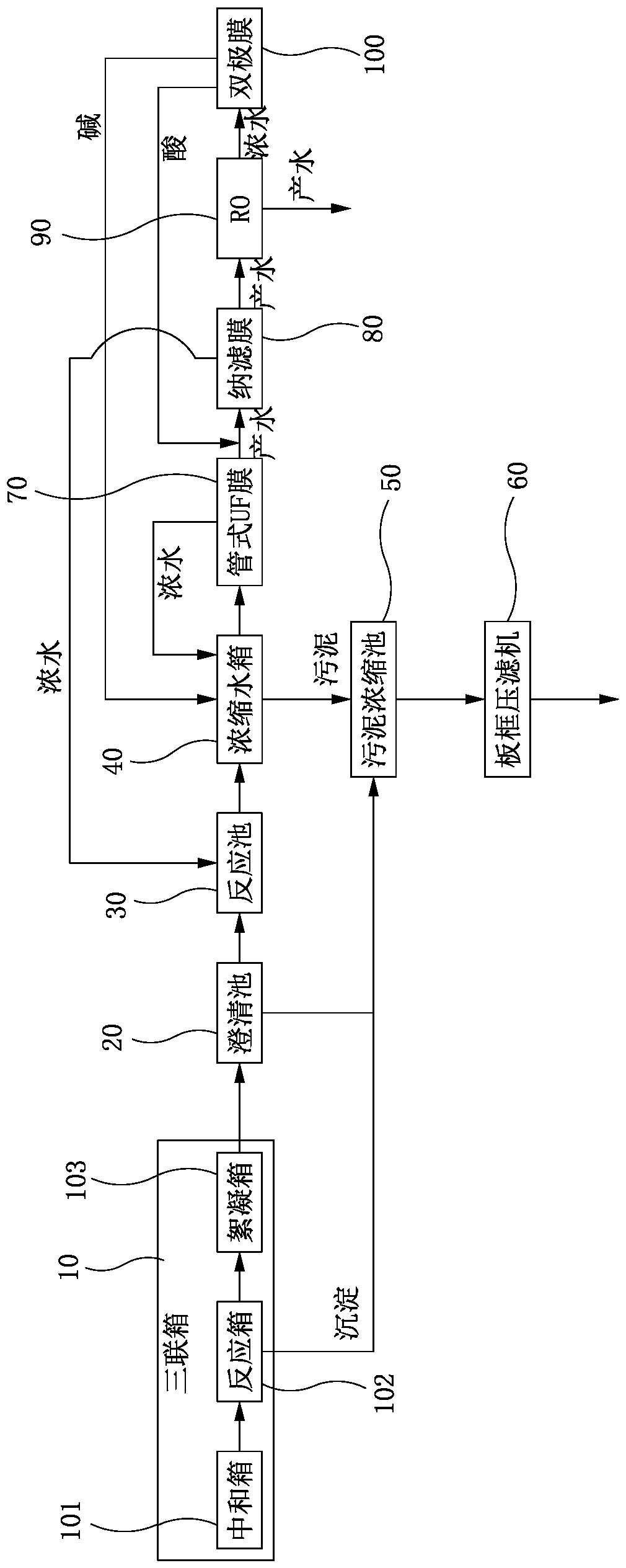

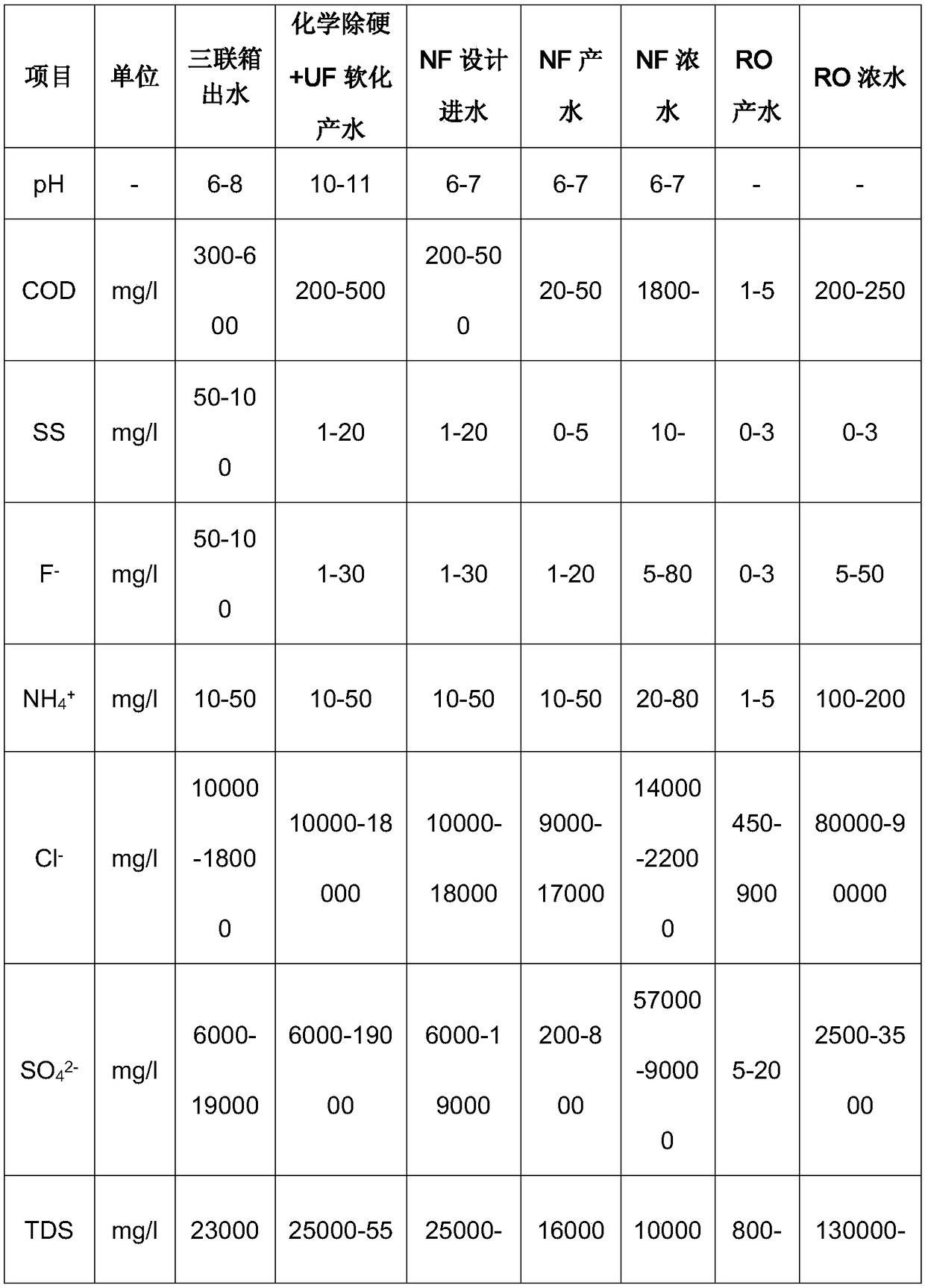

[0064] Such as figure 2 As shown, the zero-discharge treatment device for power plant desulfurization wastewater disclosed in this embodiment includes a triple box 10, a clarifier 20, a reaction tank 30, a concentrated water tank 40, a sludge concentration tank 50, and a plate-and-frame filter press 60 , tubular UF membrane module 70, nanofiltration membrane module 80, RO membrane module 90, and bipolar membrane electrodialysis system 100; wherein the triple box 10 includes a neutralization box 101, a reaction box 102, and a flocculation box 103 connected in sequence, and the flocculation box 103 is connected to the clarification tank 20, the clarification tank 20 is connected to the reaction tank 30, the reaction tank 30 is connected to the concentrated water tank 40, the sludge outlet of the concentrated water tank 40 is connected to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com