Warehousing system used for truck unloading

A storage system and truck technology, which is applied in the field of storage systems for truck unloading, can solve the problems of unsuitable moisture content and high dust removal costs in silos, and achieve the effects of reducing spillage, simple structure, and reducing dust removal costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the technical solutions of the present invention will be described in detail below with reference to the accompanying drawings. The following examples are only used to more clearly illustrate the technical solutions of the present invention, and are therefore only used as examples, and cannot be used to limit the protection scope of the present invention.

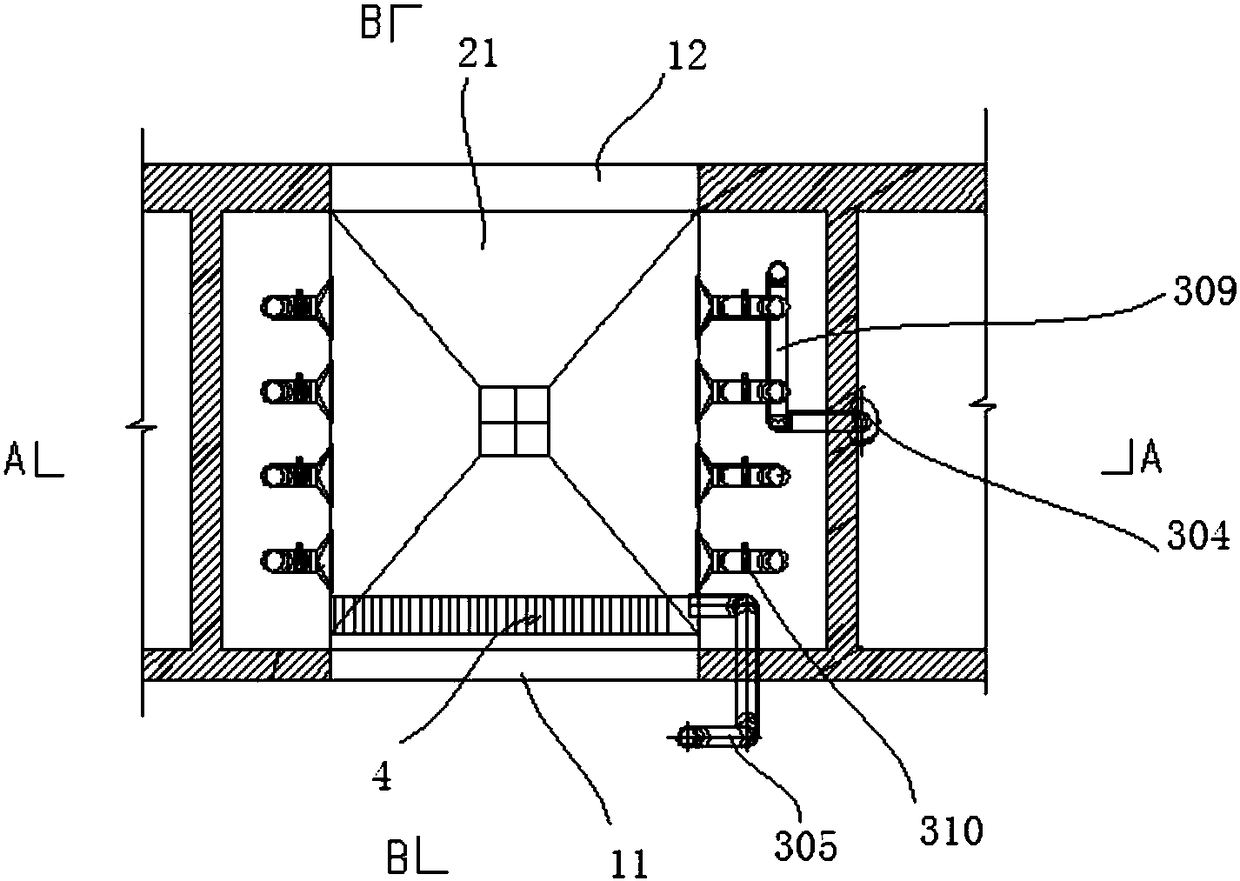

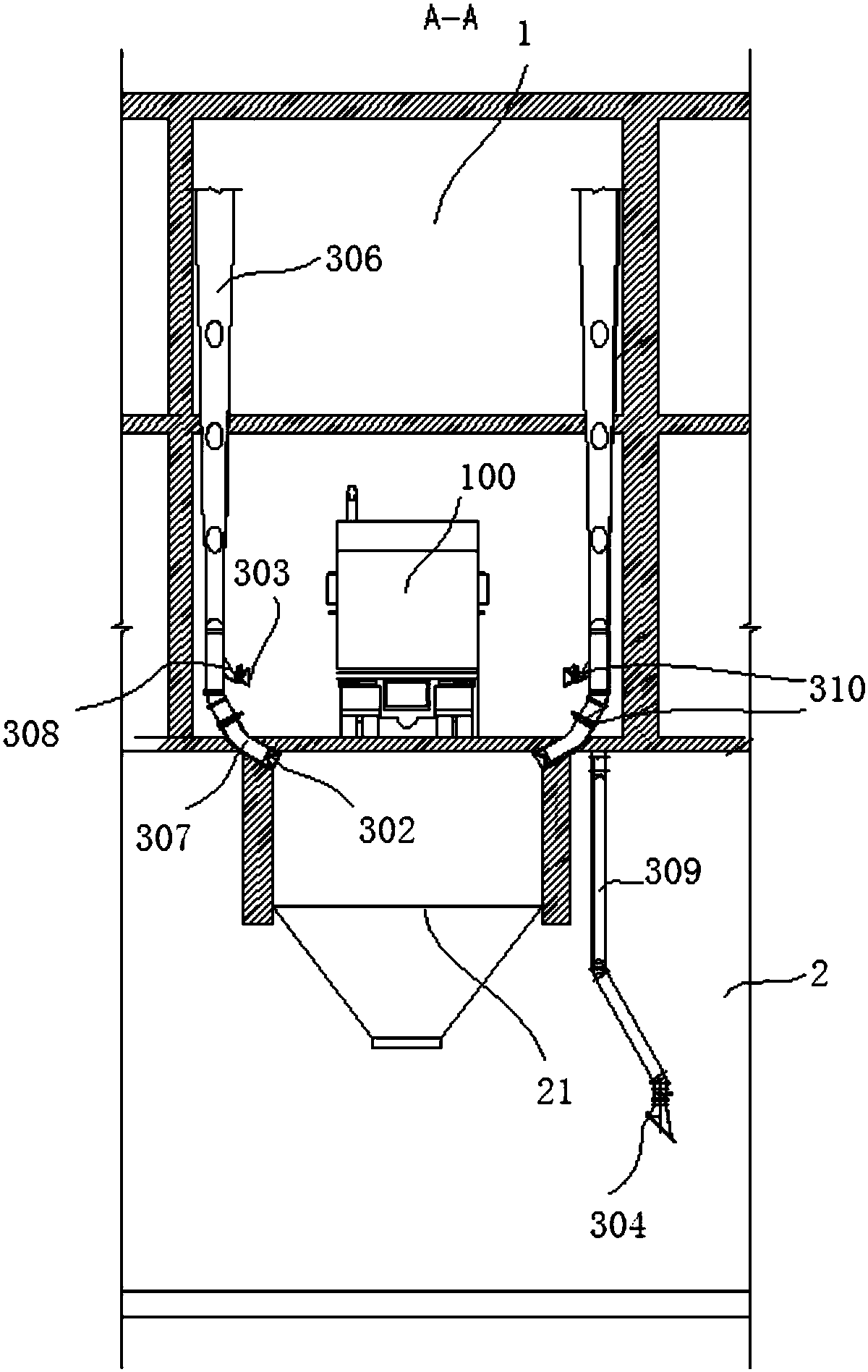

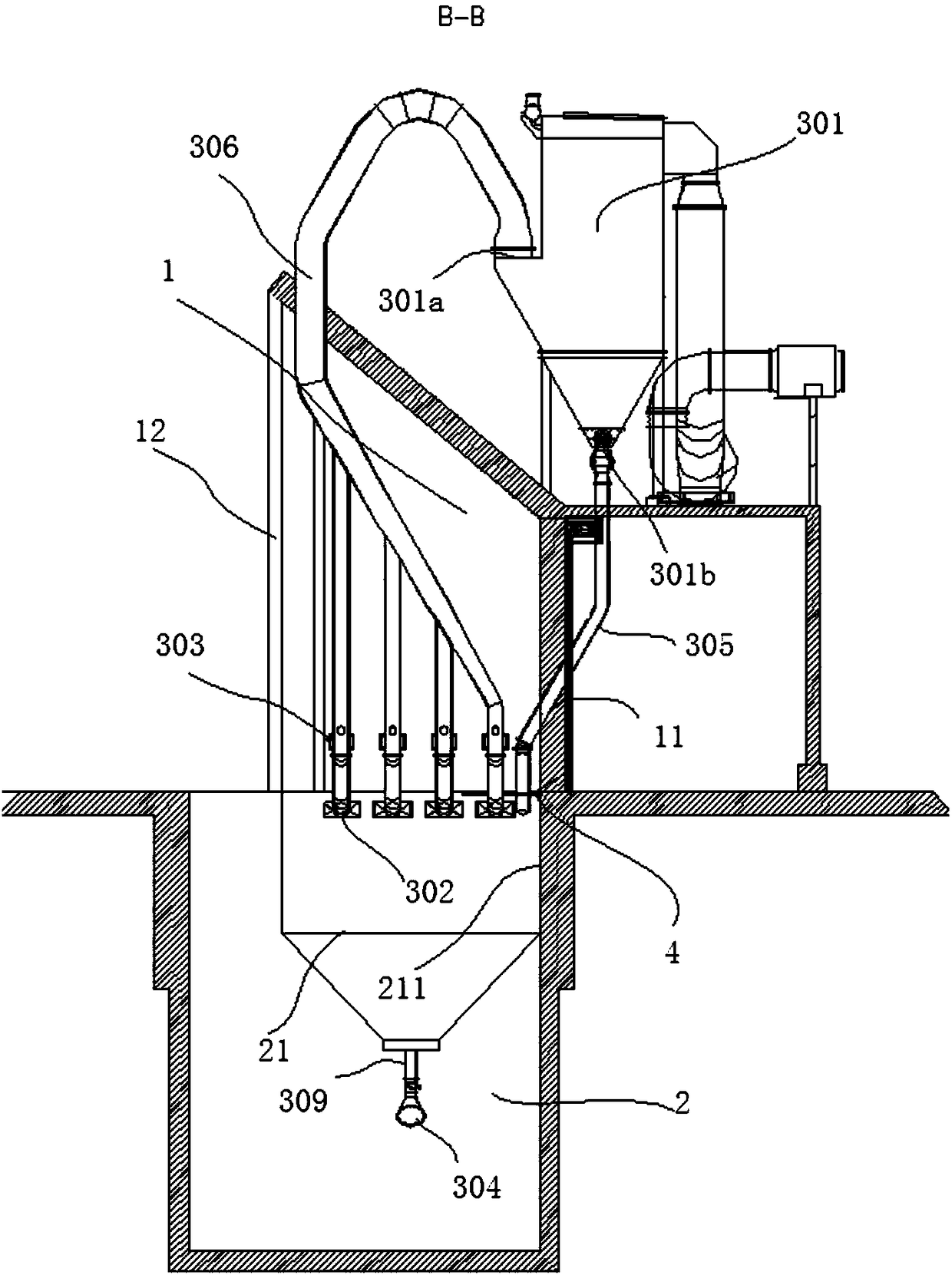

[0021] figure 1 It is a schematic structural diagram of a storage system for truck unloading according to an embodiment of the present invention, figure 2 for figure 1 The A-A view, image 3 for figure 1 The B-B oriented view, such as Figure 1-3 As shown, it includes a warehouse 1 , an underground silo 21 arranged in the warehouse 1 , a dust removal device 3 and a dust suppression baffle 4 . The warehouse 1 has a drive-in 11 and a drive-out 12 . The underground silo 21 can receive the material to be unloaded by the truck 100 through its top opening. The dust removal device 3 includes a dust co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com