A Forging Method for Improving the Grain Size of 15-5ph Stainless Steel

A technology of stainless steel and grain size, which is applied in the field of material processing, can solve the problems of easy growth of grains and achieve the effect of improving the reliability of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

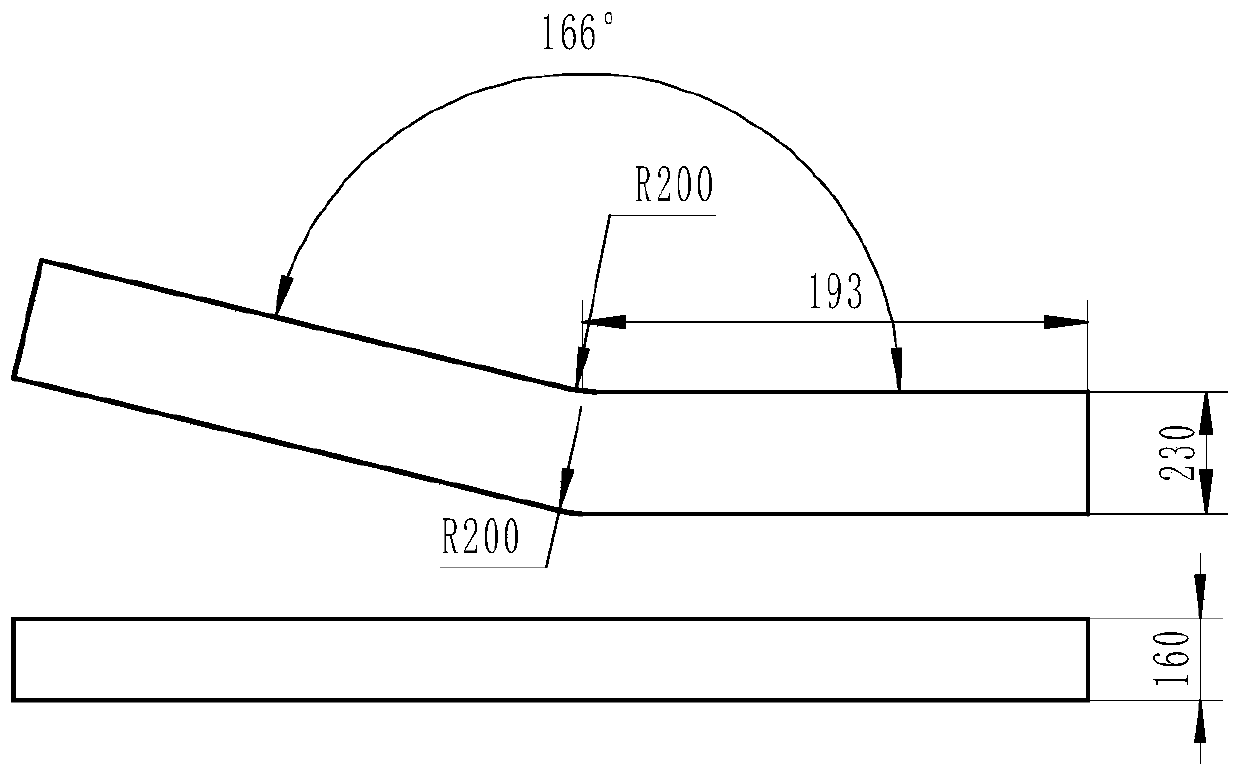

Method used

Image

Examples

Embodiment 1

[0026] 1.1 Raw materials

[0027] (1) The chemical composition of the raw material of 15-5PH stainless steel billet was re-inspected according to the standard AMS 5659, and the result was qualified, see Table 1;

[0028] Table 1 Chemical Composition of Raw Materials

[0029]

[0030] (2) The mechanical properties of raw materials are re-inspected according to the standard AMS5659, and the result is qualified, see Table 2;

[0031] Table 2 Mechanical Properties of Raw Materials

[0032]

[0033] (3) Low-magnification structure of raw materials: no metallurgical defects, standard: AMS 5659;

[0034] (4) High-magnification structure of raw materials: no free ferrite, standard: AMS 5659;

[0035] (5) Raw material flaw detection: According to Φ2.0 flat bottom hole, the result is qualified, standard: A grade in AMS-STD-2154;

[0036] Grain size evaluation metallographic diagram of raw materials figure 2 shown.

[0037] 1.2 Forging, heat treatment and inspection

[0038...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com