A semi-automatic intermittent feeding vibrating screening device

A vibrating screening and feeding device technology, which is applied in the fields of filtration, solid separation, chemical instruments and methods, etc., can solve the problems of low degree of automation, easy blockage of sieve holes, single movement form, etc., and achieves high degree of automation and applicable The effect of wide range and high classification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments and illustrations.

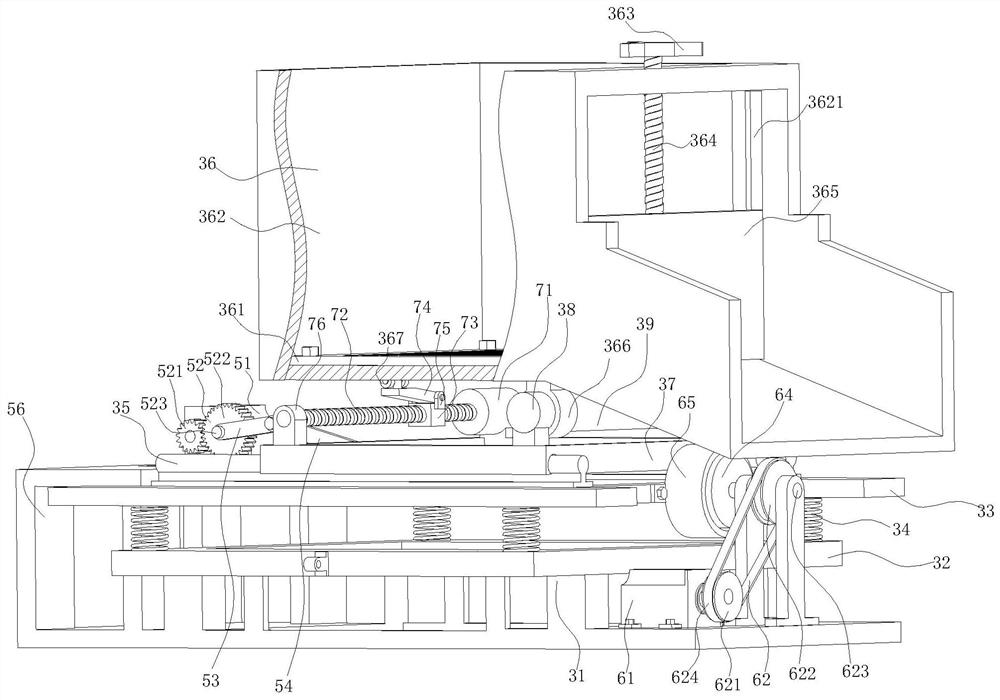

[0024] Such as figure 1 As shown, a semi-automatic intermittent feeding vibrating screening device includes a frame 1, a feeding device 2, a sieve body 3, a driving device 4, a driving device 2 5, a driving device 3 6, an adjusting device 7, and a controller 8. The vibration branch chain 9, the frame 1 includes an upper plate 11, an inclined plate 12, a base plate 13, a base plate 2 14, a leg 15, a vertical plate 16, a vertical plate 2 17, and a motor seat 18. The motor seat 18 described above is fixedly connected on the upper plate 11, and the described supporting legs 15 have six, which are all fixedly connected on the upper plate 11, and the described inclined plate 12 is fixedly connected on the left side four supporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com