A rapid detection method for the void degree of the seam

A detection method and seam separation technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of effective measurement, large workload, time-consuming and labor-intensive, etc., and achieve the effect of improving accuracy and avoiding re-measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

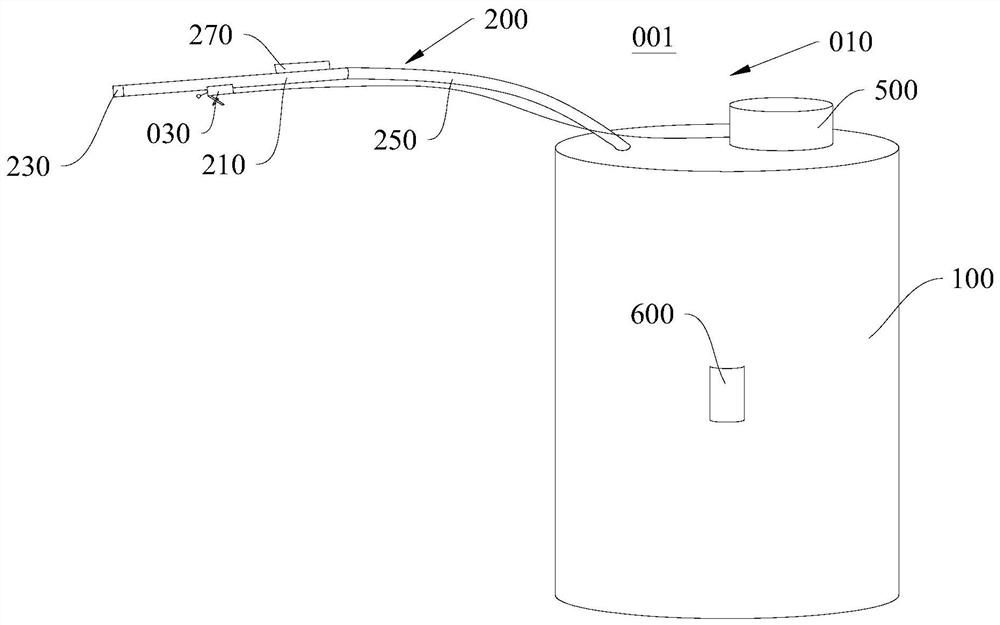

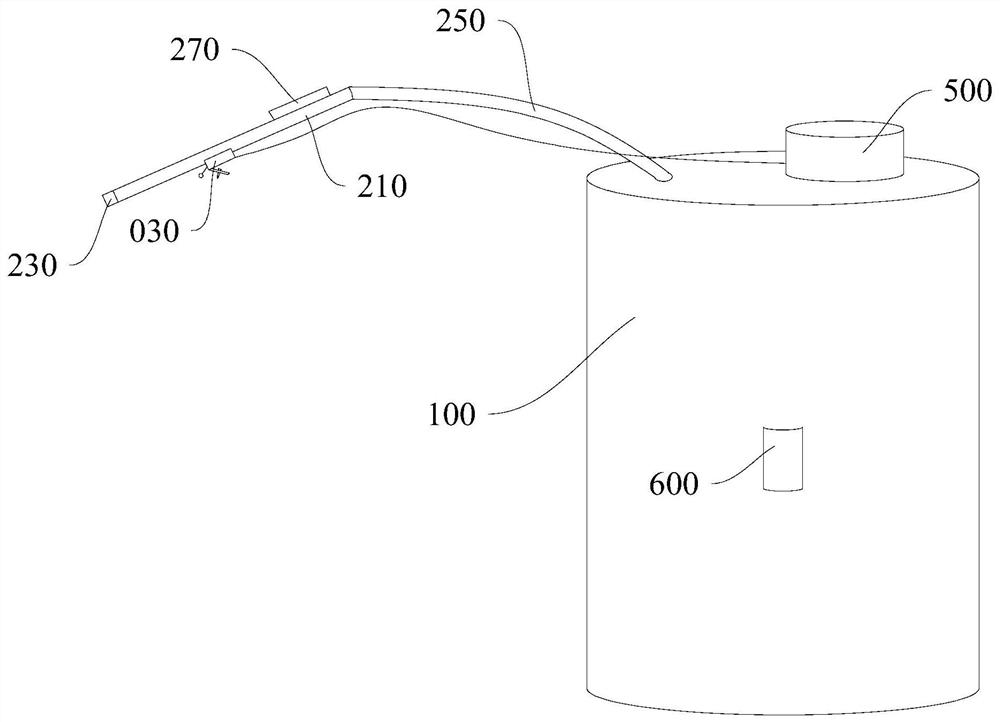

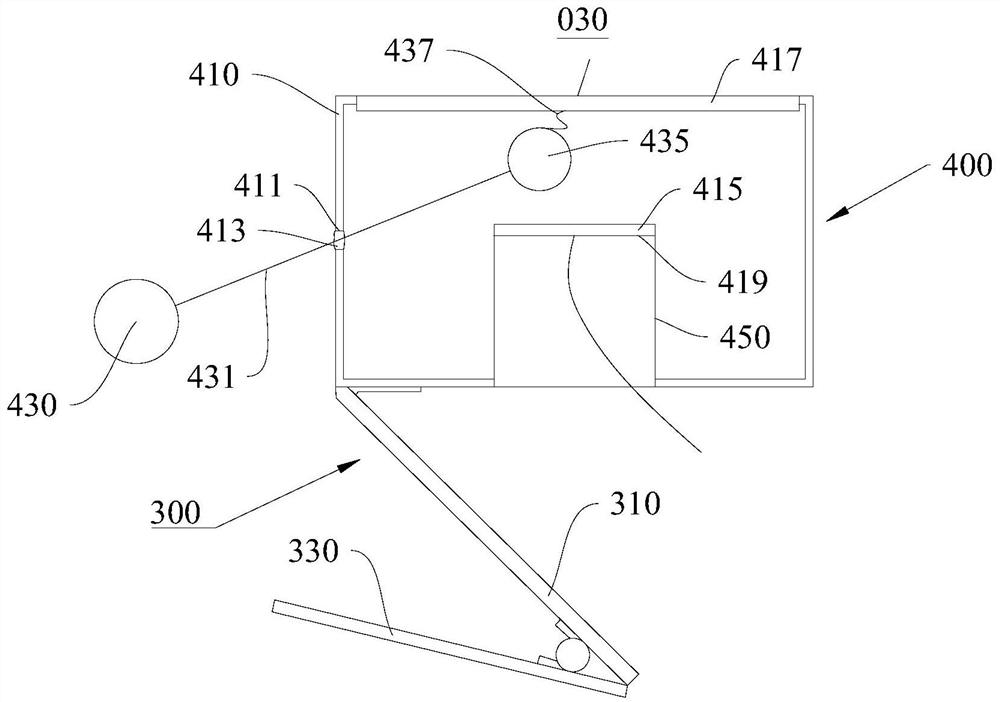

[0031] This embodiment provides a fast detection method for the degree of voiding from the seam, please refer to figure 1 , this rapid detection method for the degree of voiding of the gap is used to detect the degree of voiding of the gap between layers of the track structure, including steps:

[0032] First measure the width b of the seam, where the width of the seam is the gap of the small span of the seam, in the present embodiment, use a feeler gauge to measure the width of the seam;

[0033] Along the length direction of the separation seam, the liquid injection pipe is buried inside the separation seam, and the separation seam is sealed along the length direction of the separation seam, and an observation port is also arranged on the separation seam;

[0034] The perfusion is carried out inside the separation gap, and the perfusion can directly use water. After the liquid flows out of the observation port, the perfusion is stopped, and the volume V of the perfused liqui...

Embodiment 2

[0045] This embodiment provides a liquid injection device 001, please refer to figure 1 , this liquid injection device 001 is used to detect the degree of voiding of the rail gap, and includes a liquid injection machine body 010 and a monitoring part 030 .

[0046] The liquid injection machine body 010 includes a liquid storage part 100 and a liquid outlet part 200. There is a liquid storage space for liquid storage in the liquid storage part 100. In this embodiment, the liquid storage part 100 is used to store tap water. In other embodiments In the process, liquids of different viscosities can also be stored according to different site conditions to accurately measure the track separation in different situations. The liquid storage part 100 is made of a transparent plastic barrel, and a water injection hole is provided on the liquid storage part 100, and water is injected into the liquid storage space through the water injection hole. Since the liquid storage part 100 is made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com