Hard puncture-proof material and preparation method thereof

A stab-proof, hard technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of looseness, easy deformation, easy generation of voids, easy deformation, etc., to achieve good stab-proof effect, Not easy to pierce, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a hard stab-proof material and a preparation method thereof. The hard stab-proof material of the invention has small deformation, good stab-proof effect, is difficult to puncture, and has low cost.

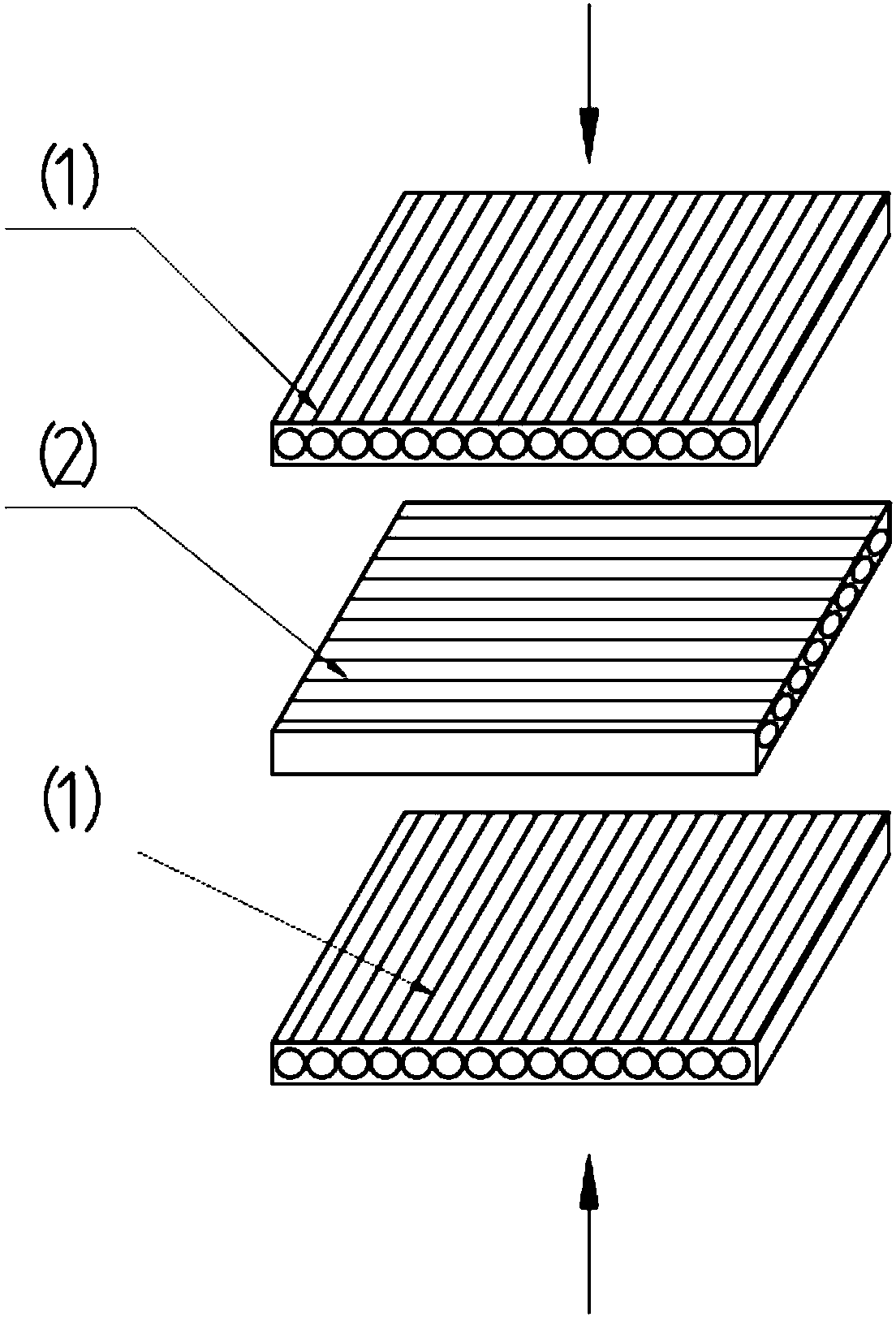

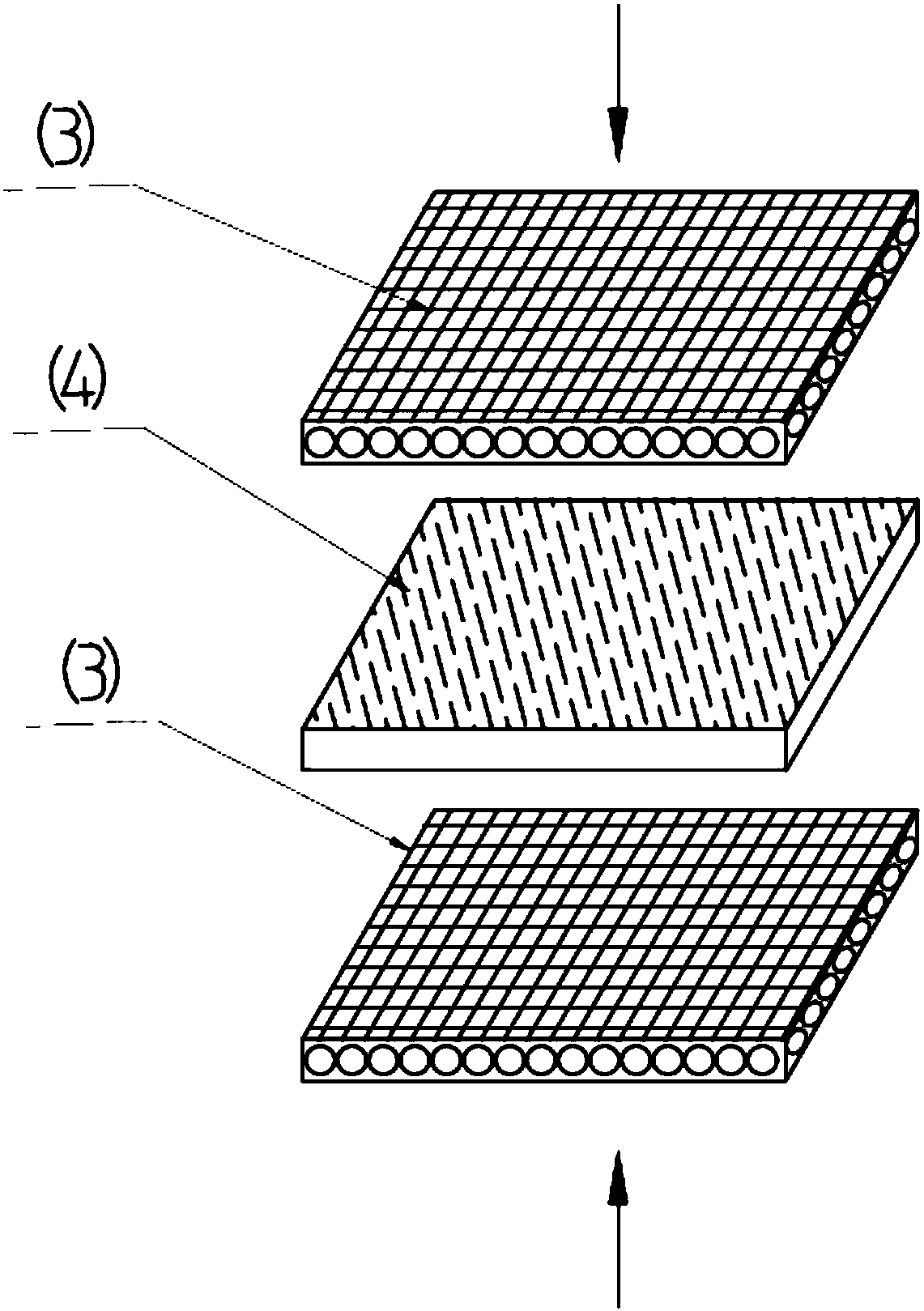

[0034] See figure 1 and figure 2 , the hard anti-stab material of the present invention is made of such as figure 1 The multi-layer unidirectional continuous glass fiber reinforced thermoplastic prepreg tapes (1) and (2) are laminated and pressed at 0° / 90°, or as figure 2 As shown, it is composed of two layers of 0° / 90° composite material (3) and one layer of thermoplastic lightweight felt board (4). The ratio of the thickness of the thermoplastic lightweight felt board to the thickness of the 0° / 90° composite material is 1:(0.5-3):1.

[0035] Wherein, the unidirectional continuous glass fiber reinforced thermoplastic prepreg tape is a prepreg sheet in which continuous glass fibers are completely impregnated in thermoplastic resin.

[0036] The ...

Embodiment 1

[0044] The hard anti-stab material provided in this embodiment is made of 12 layers of unidirectional continuous glass fiber reinforced polypropylene prepreg tapes laminated and pressed at 0° / 90°.

[0045] The specific preparation method is: Lay 12 layers of 0.3mm thick unidirectional continuous glass fiber reinforced polypropylene prepreg tape (glass fiber mass percentage 70%) at 0° / 90°, put it into a flat press and heat it Press molding, the thickness of the finally obtained hard stab-proof material plate is 3.2mm. The hot-pressing process parameters are: hot-pressing temperature 180°C, hot-pressing time 3min, pressure 2MPa. The obtained hard stab-resistant material plate was tested according to the standard of GA68-2008 "Police Stab-resistant Clothing", and the test result was no penetration.

Embodiment 2

[0047] The hard anti-stab material provided in this embodiment is made of two layers of 0° / 90° composite material and one layer of thermoplastic lightweight felt board.

[0048] The specific preparation method is as follows: 6 layers of 0.3mm thick unidirectional continuous glass fiber reinforced polypropylene prepreg tape (glass fiber mass percentage 70%) are laid at 0° / 90°, and pre-pressed into 0° / 90° at 260°C. ° / 90° composite material sheet; then the material is laid according to (0° / 90°) composite material / thermoplastic lightweight felt board / (0° / 90°) composite material structure, in which the thickness of thermoplastic lightweight felt board is 1.2 mm, put it into a flat press after laying and hot-press forming, and the thickness of the finally obtained plate is 4mm; wherein, the mass ratio of glass fiber and polypropylene fiber or glass fiber and polypropylene wire drawing in the thermoplastic lightweight felt board is 1:0.7. The hot-pressing process parameters are: hot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com