Extruder die head and extruder

A technology of extruder and die head, which is applied in the field of extrusion molding equipment, and can solve problems such as affecting the flow direction of the extrusion medium, uneven distribution of the medium, and rupture of the pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

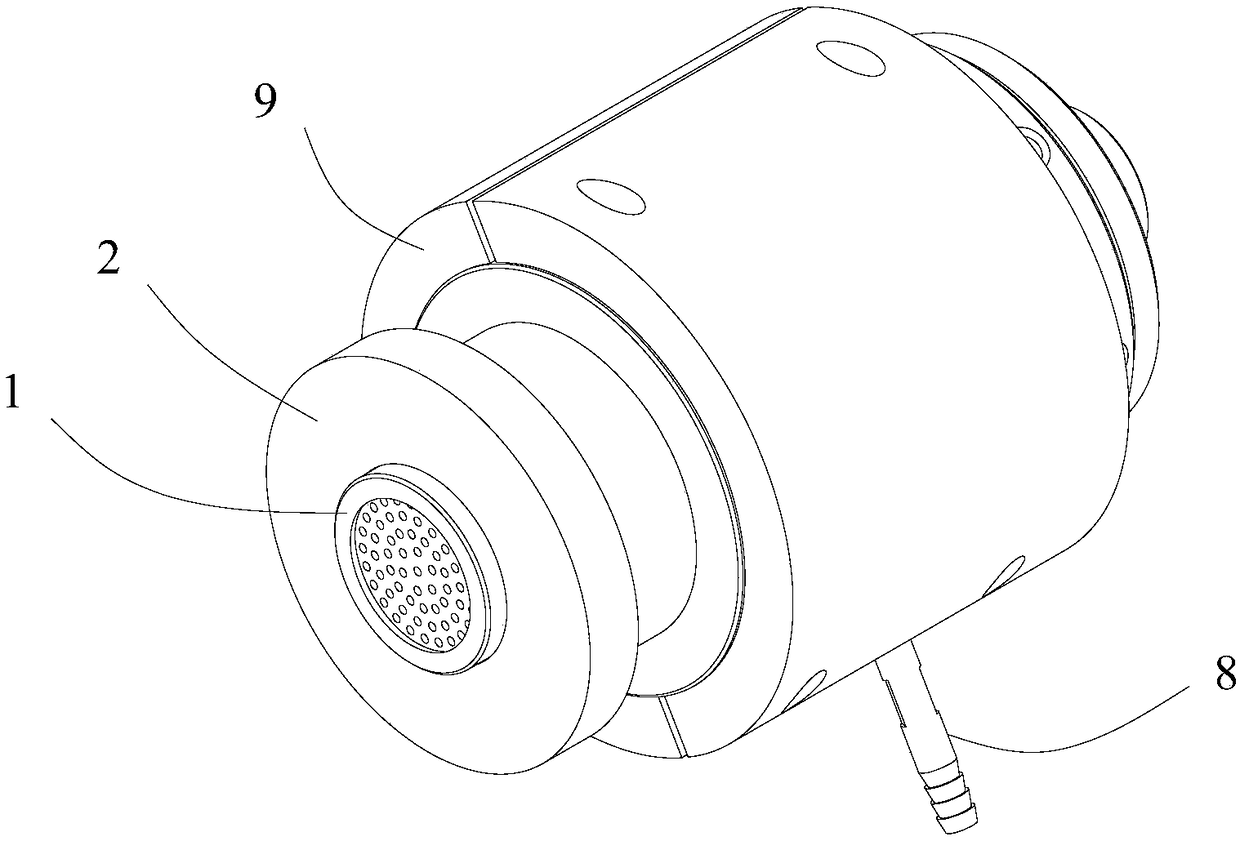

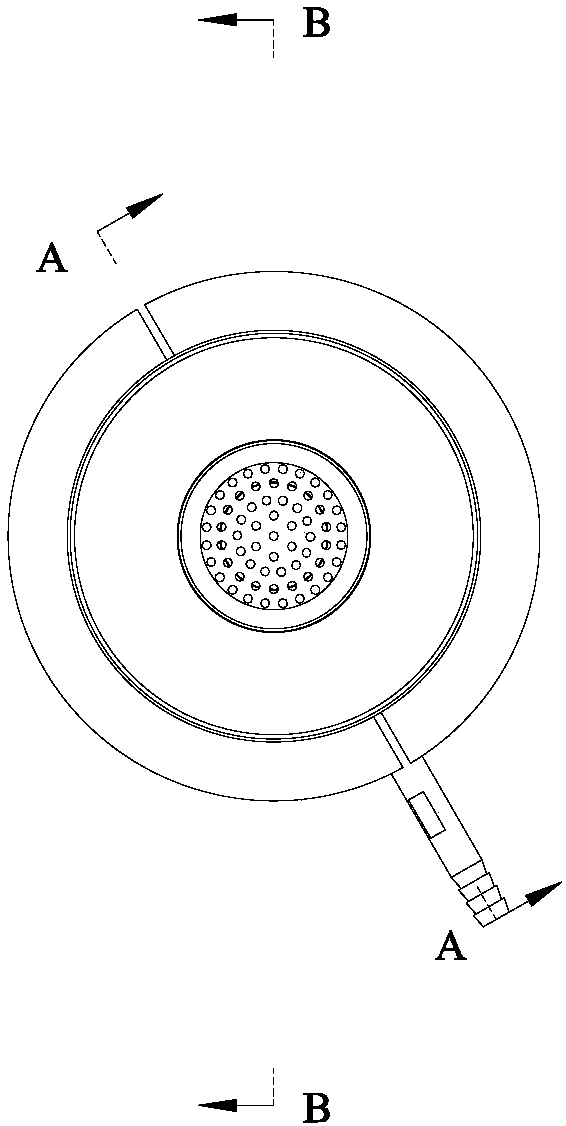

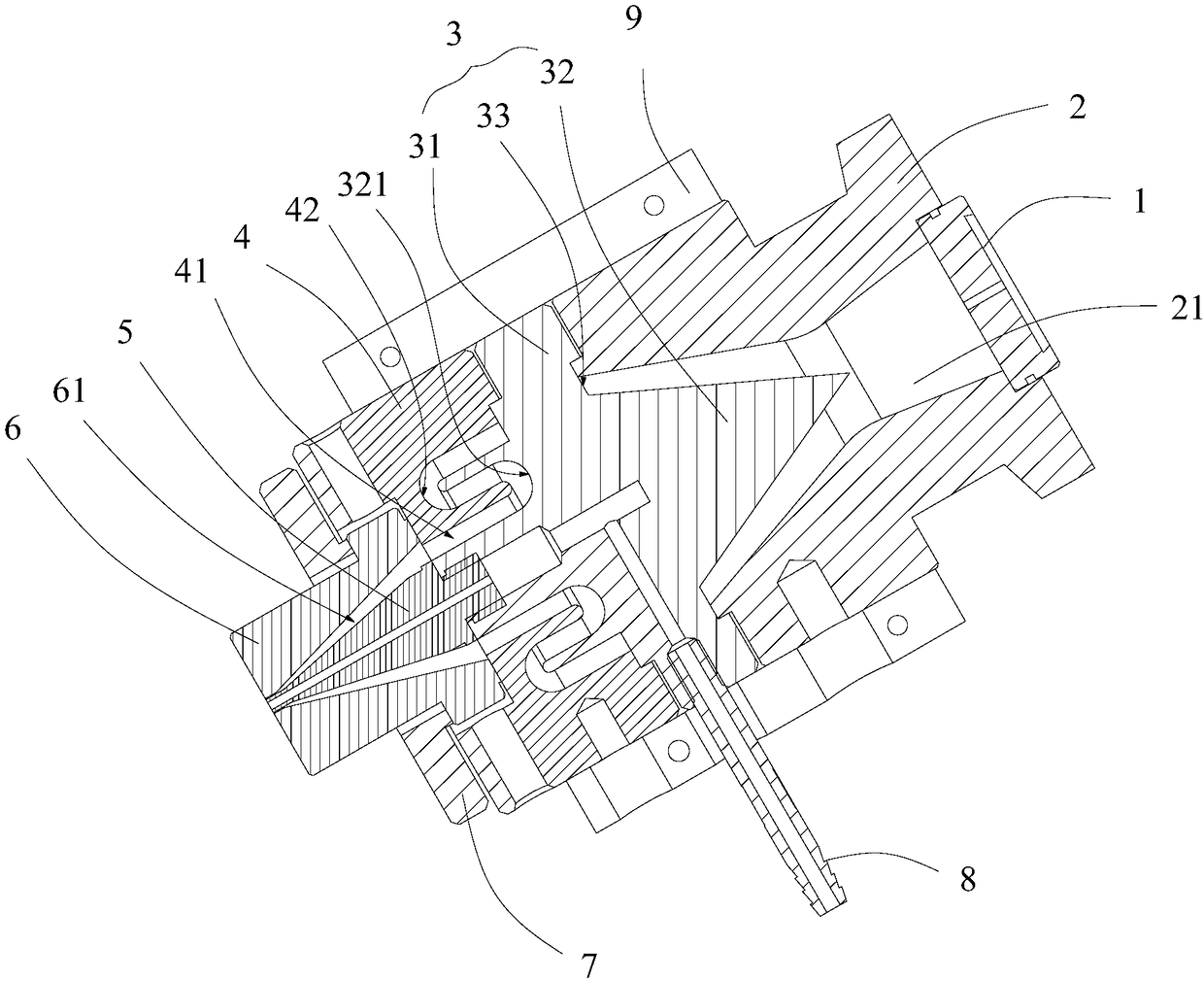

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] The present invention provides an extruder die head, which has a passage against the extrusion direction, wherein the extrusion direction is defined as from the head end to the tail end of the extruder die head. In the present invention, the design of the channel in the reverse direction of extrusion is mainly to eliminate the influence of the barrier medium on the middle edge of the diverter shuttle of the die mentioned below (similar to the connecting part of the diverter shuttle mentioned in the background section). The channel design in the outlet direction can make the extrusion medium still get a chance to be fully mixed after being separated by the ribs, so that the subsequent extrusion medium can be evenly distributed, and the problem of the joint line that is easily caused by the existence of the ribs can be overcome.

[0025] B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com