Welding method of target material assembly and target material assembly welding structure

A welding method and welding structure technology, which is applied in welding equipment, semiconductor devices, circuits, etc., can solve the problems that the quality of aluminum target components needs to be improved, and achieve the effects of ensuring welding strength, reducing weld width, and reducing the use of solder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] It can be seen from the background art that the quality of the aluminum target assembly formed in the prior art still needs to be improved.

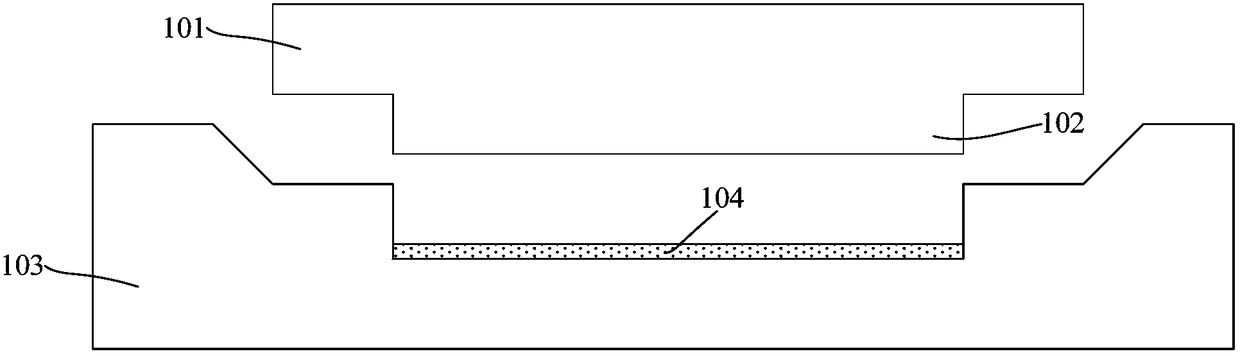

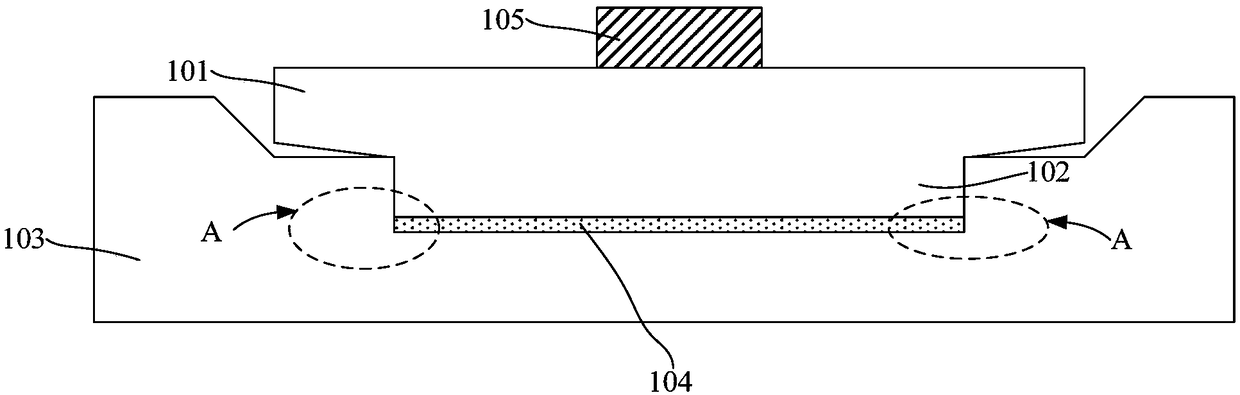

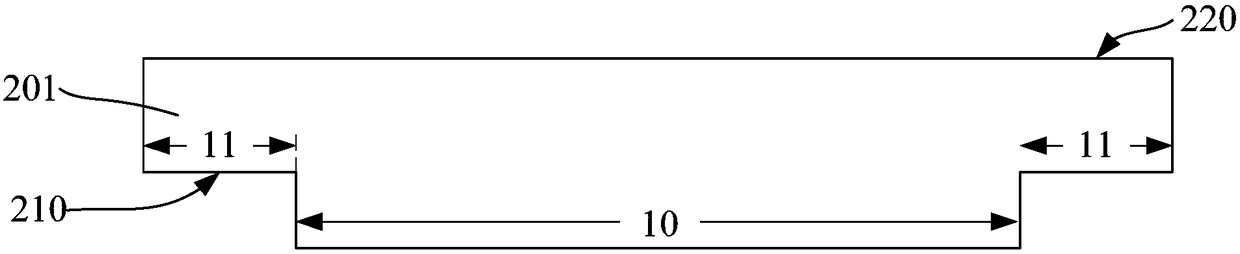

[0039] Combining with a welding method of aluminum target components, the reasons why the quality of aluminum target components needs to be improved are analyzed. figure 1 and figure 2 It is a schematic cross-sectional structure diagram corresponding to each step of a welding method for an aluminum target assembly.

[0040] refer tofigure 1 , provide an aluminum target 101 and an aluminum back plate 103 ; put solder 104 on the welding surface of the aluminum back plate 103 .

[0041] Generally, it is considered that when the aluminum target 101 and the aluminum back plate 103 are welded, the greater the amount of solder input, the greater the welding strength of the formed aluminum target assembly. For this purpose, the welding surface of the aluminum target 101 has a step 102, and correspondingly, the welding surface of the al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com