Continuous suspended dirt filtering device and filtering and back-flushing method

A filtering device and dirt technology, which is applied in the field of sand filtration and water purification, can solve the problems of reduced filtration speed, reduced water production capacity, and increased filtration resistance, achieving the effects of stable operation, saving floor space, and improving processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

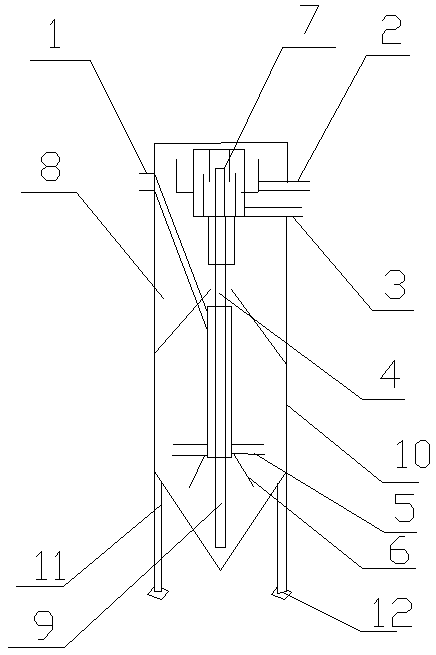

[0019] A continuous suspended dirt filtering device, which consists of: a sand filter tank 10, the sand filter tank is connected to the clean water pipe 3, the clean water pipe is connected to the sand water separator 7, and the sand filter tank is connected to the sand water separator 7. The water separator is respectively connected with the sewage pipe 2 and the air sand lifting pipe 4, and the air sand lifting pipe is respectively connected with the water inlet pipe 1, the air lift pump 9, and the water inlet distribution pipe 5, and the water inlet distribution pipe is respectively connected with the Backflow sand bucket 6 is connected.

Embodiment 2

[0021] According to the continuous suspended dirt filtering device described in Embodiment 1, the sand filter tank is connected to the filter layer 8 and the support frame 11 respectively, and a ground fixing plate 12 is installed under the support frame.

Embodiment 3

[0023] According to the continuous suspended dirt filtering device described in embodiment 1 or 2, the diversion sand bucket is conical, and the sand-water separator is a cross-ring type installed on the upper part of the sand filter cartridge and the air sand lifting pipe. Vertically connected, the water inlet pipe is connected to the air sand lifting pipe at an angle of 30 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com