Drilling device for keyboard circuit board

A technology of keyboard circuit board and drilling device, which is applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc. It can solve the problems of destroying the conductive layer, inconvenience for operators, adhesion, etc., and achieve the effect of accelerating cooling and solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

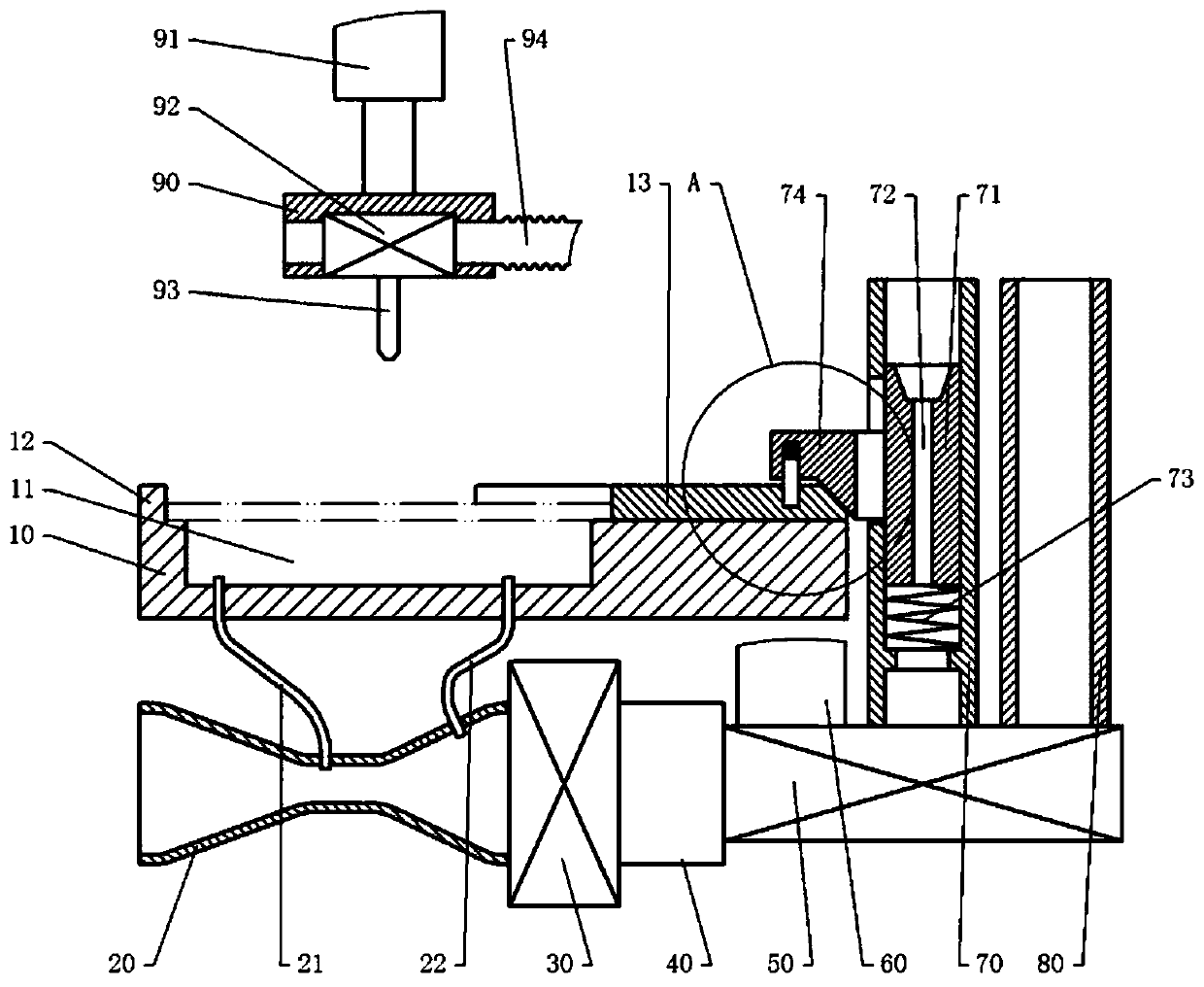

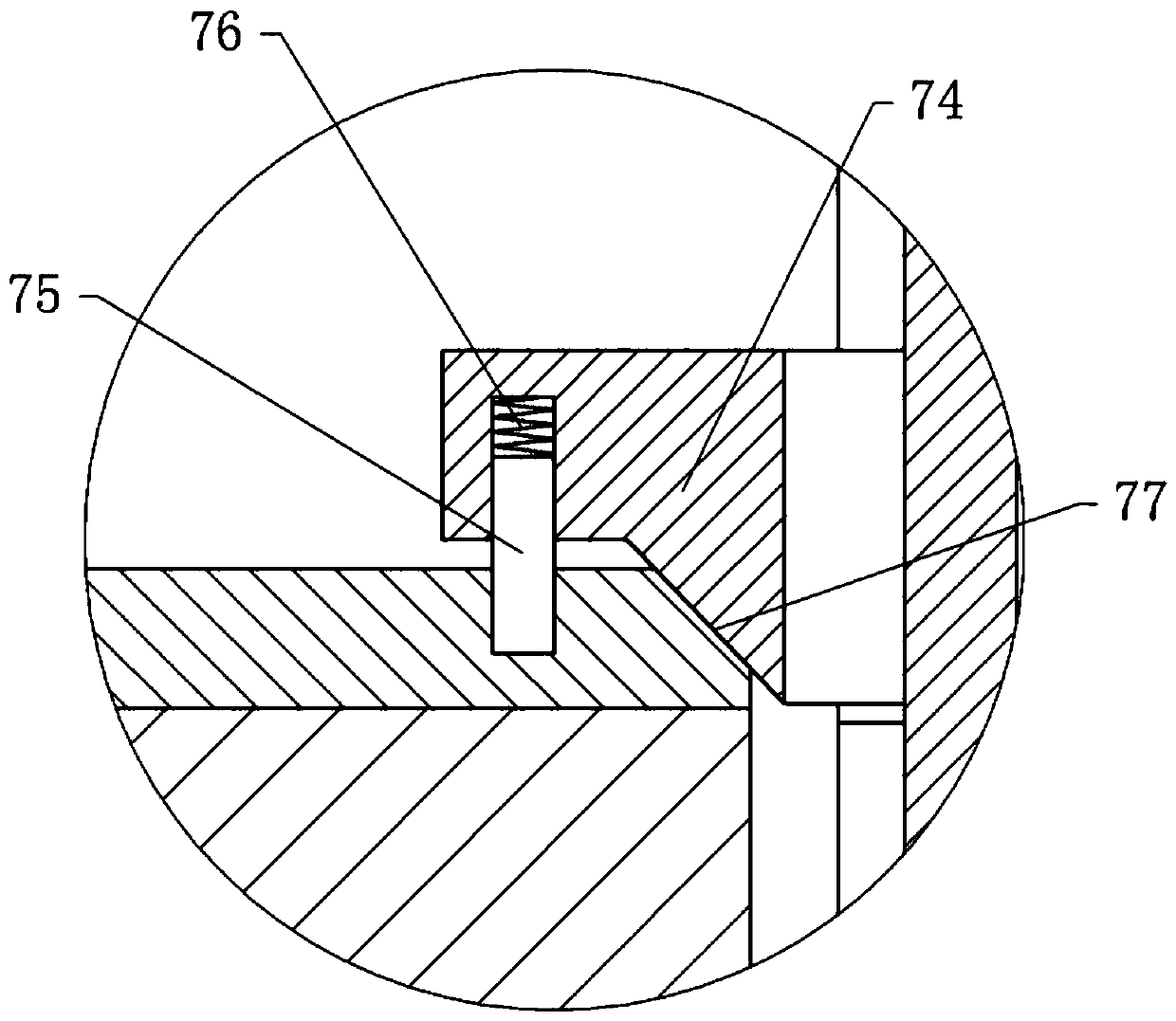

[0022] The reference signs in the accompanying drawings of the description include: seat body 10, groove 11, limiting rib 12, limiting block 13, first air duct 20, first suction tube 21, second suction tube 22, fan 30, second Air duct 40, reversing valve 50, first air intake pipe 60, second air intake pipe 70, pneumatic block 71, air hole 72, second spring 73, extruding block 74, positioning column 75, third spring 76, wedge surface 77. The third air intake pipe 80, slide seat 90, feed cylinder 91, air motor 92, drill bit 93, bellows 94.

[0023] The embodiment is basically as figure 1 , figure 2 Shown:

[0024] The drilling device of the keyboard circuit board of the present embodiment comprises a frame, a base body 10, a first air duct 20, a second air duct 40 and a drilling portion arranged above the base body 10, and the base body 10 is fixed on the frame . Dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com