Tobacco distributing equipment

A tobacco and equipment technology, which is applied in the fields of threshing and redrying and shred material distribution equipment and equipment in the tobacco industry, can solve the problems of long adjustment time, low adjustment accuracy, and position change of material distribution rollers, etc., so as to achieve simple control and improve adjustment The effect of high precision and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

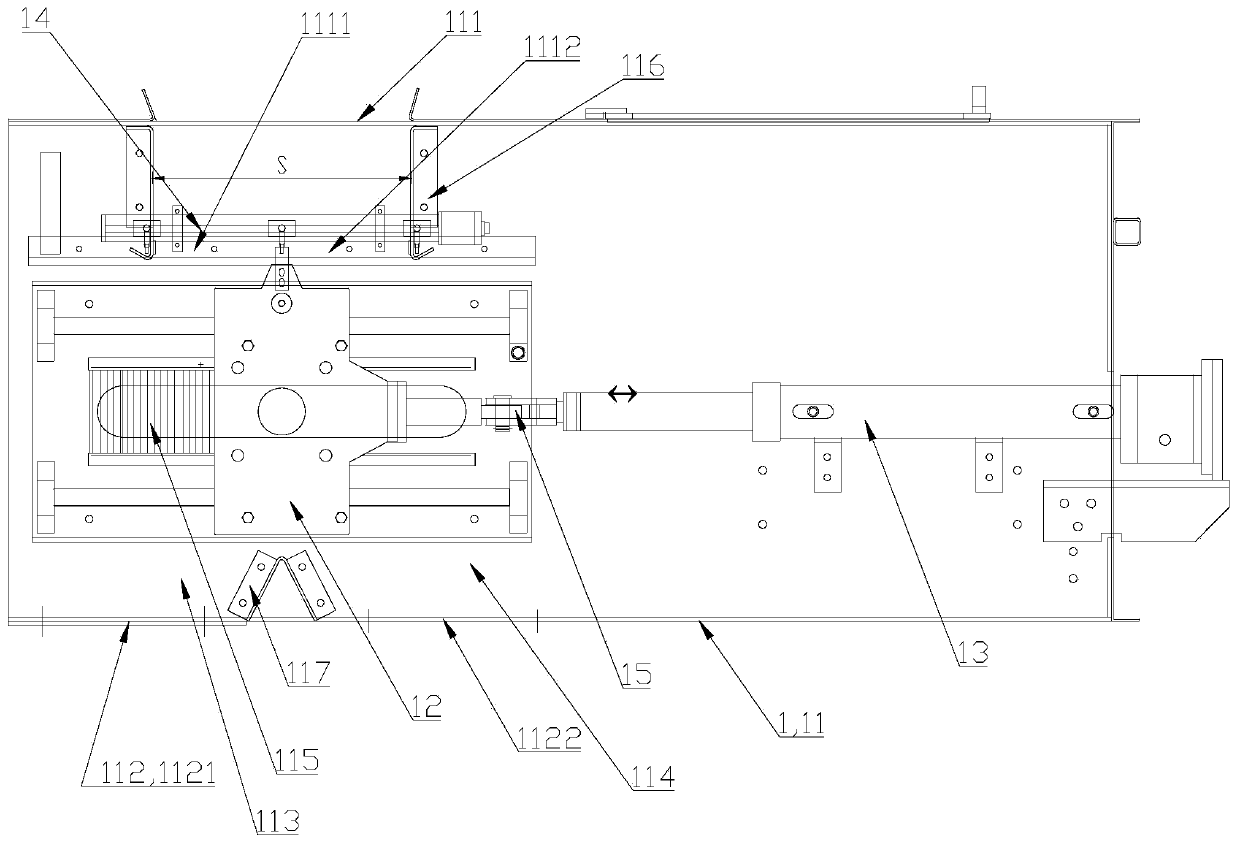

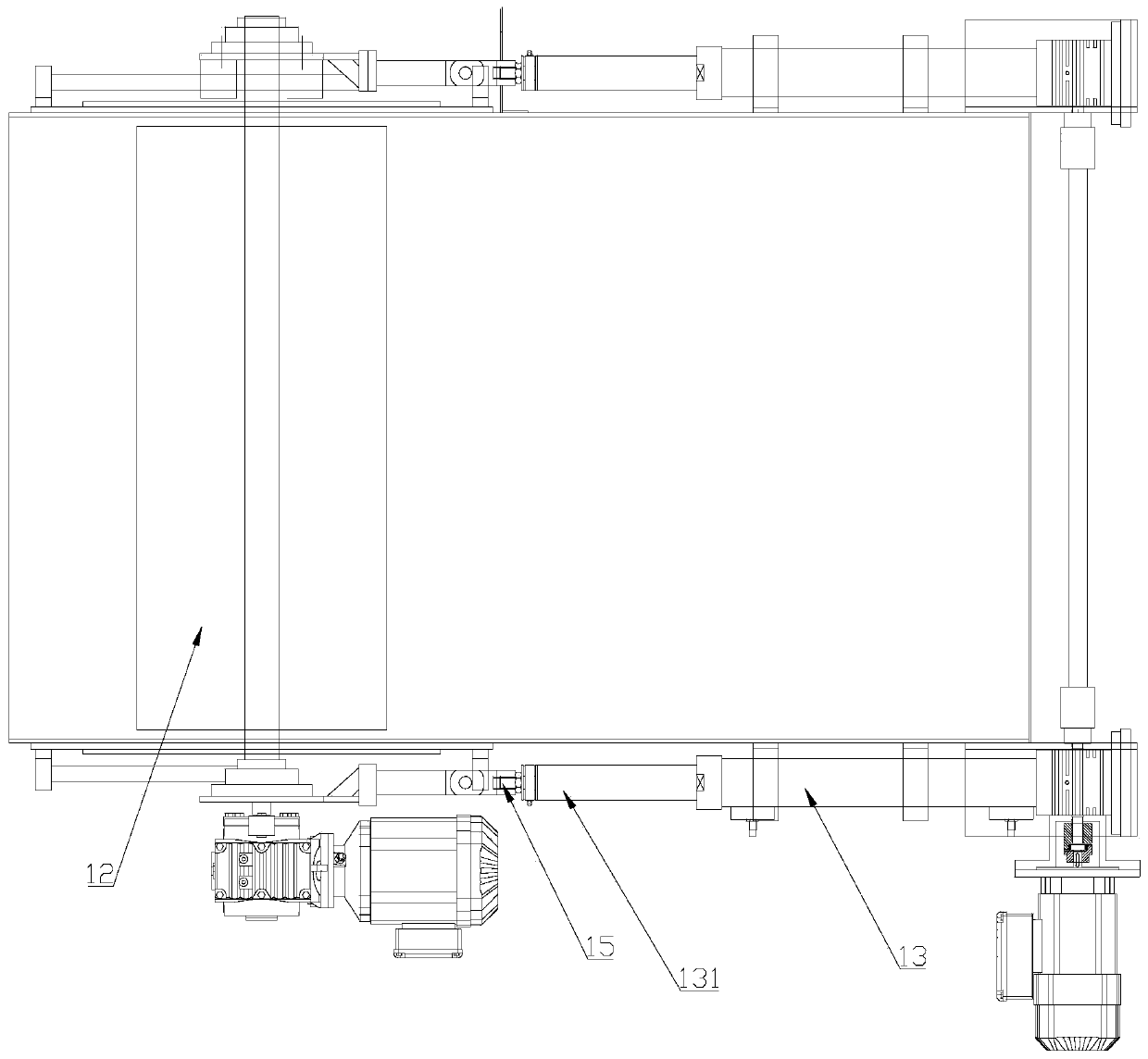

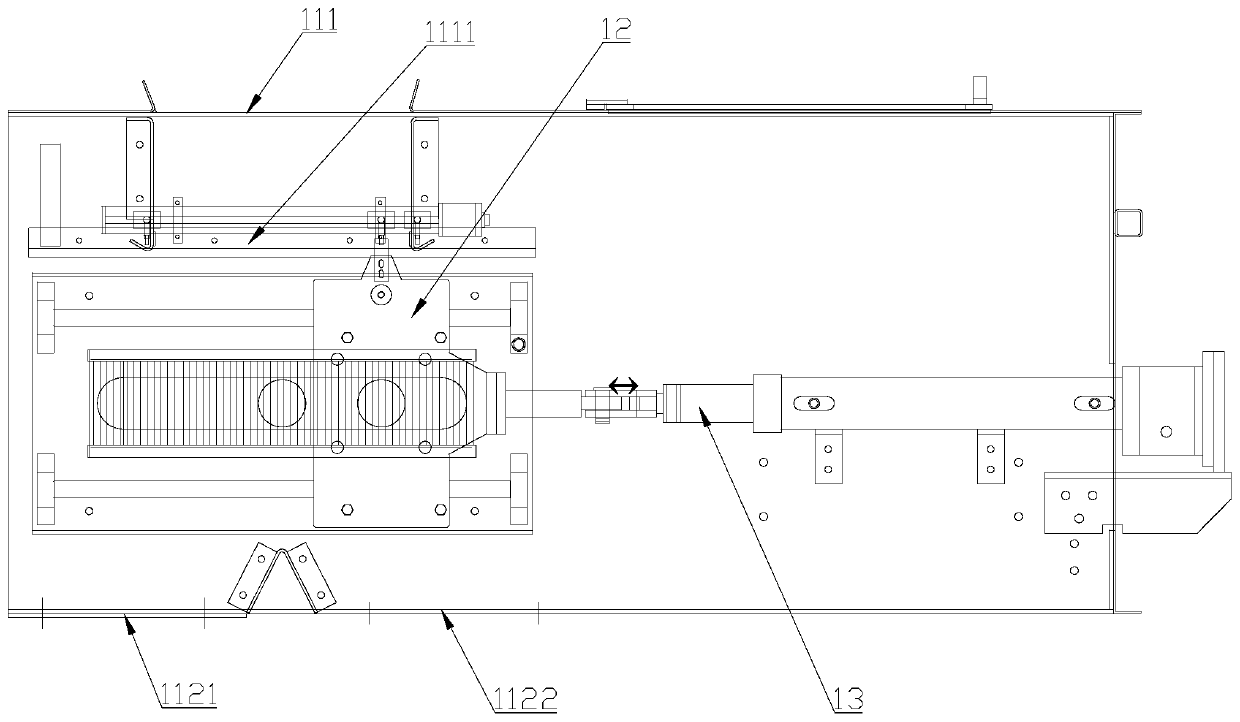

[0034] Such as Figure 1 to Figure 2 As shown, a tobacco distributing device 1 is introduced in this embodiment. The tobacco distributing device 1 includes a housing 11, an inlet 111 arranged on the housing 11 and at least two outlets 112. The tobacco The material distribution device 1 also includes a material distribution roller device 12 and an electric push rod device 13. The material distribution roller device 12 is arranged inside the housing 11 of the tobacco distribution device 1, between adjacent discharge ports 112, and feeds the material Port 111 is divided into a plurality of distribution ports, and each distribution port is connected with the corresponding discharge port; the electric push rod device 13 is connected with the distribution roller device 12, and drives the distribution roller device 12 to move, to adjust the The size of the material opening, thereby adjusting the amount of material that enters from each material distribution port and is discharged thr...

Embodiment 2

[0042] Such as Figures 1 to 2 As shown, the tobacco distributing equipment 1 also includes a connection device 15, the electric push rod device 13 is arranged horizontally, and is fixedly connected with the distribution roller device 12 through the connection device 15, and the electric push rod device 13 is stretched through the horizontal expansion and contraction of the push rod 131 Drive the distribution roller device 12 to move back and forth, thereby adjusting the size of the first distribution opening 1111 and the second distribution opening 1112 .

[0043] In this embodiment, the electric push rod device 13 is arranged on the outside of the casing 11, and is fixedly connected with the part of the distribution roller device 12 passing through the casing 11 through the connection device 15, and the electric push rod device 13 is driven by the connection device 15 The part of the distribution roller device 12 passing through the housing 11 moves back and forth, and the p...

Embodiment 3

[0049] Such as Figure 1 to Figure 2 As shown, in this embodiment, the distributing equipment 1 also includes a displacement sensor 14 arranged on the housing 11 for detecting the position of the distributing roller device 12, and the electric push rod device 13 receives the signal from the displacement sensor 14 to drive The distribution roller device 12 starts and stops at any position within the range S. By setting the displacement sensor, the displacement sensor can detect the position of the distributing roller device, and feed back the point control signal to the electric push rod device. Start and stop at any position.

[0050] In this embodiment, the measuring range S is the distance between the two ends of the feeding port along the moving direction of the material distribution roller device 12 .

[0051] image 3 It shows a schematic structural diagram of the tobacco distributing device 1 when all the materials are discharged from the first discharge port 1121. At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com