Camera module

A camera module and lens technology, applied in image communication, television, optics, etc., which can solve the problems of space occupation, limited tolerance gap and fit, and large volume of supporting objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

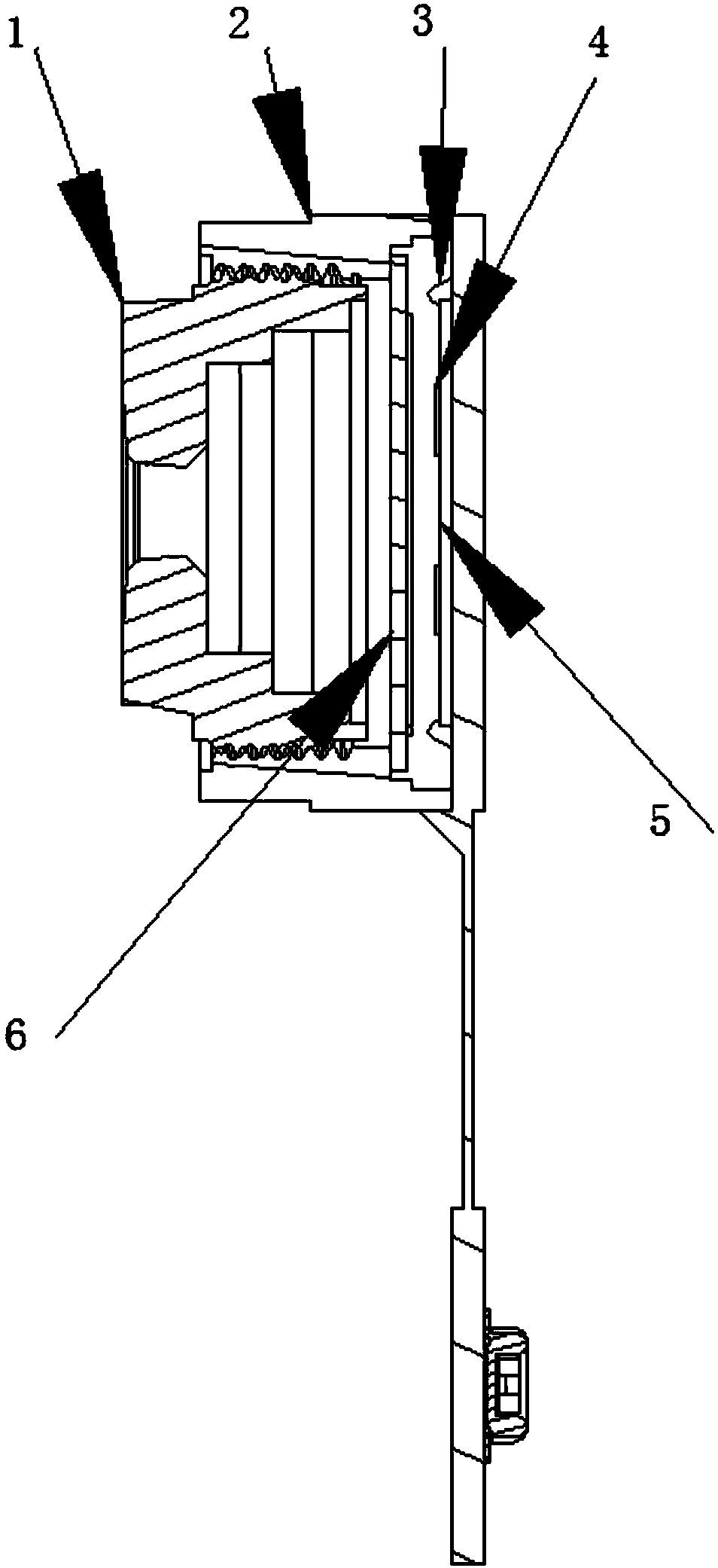

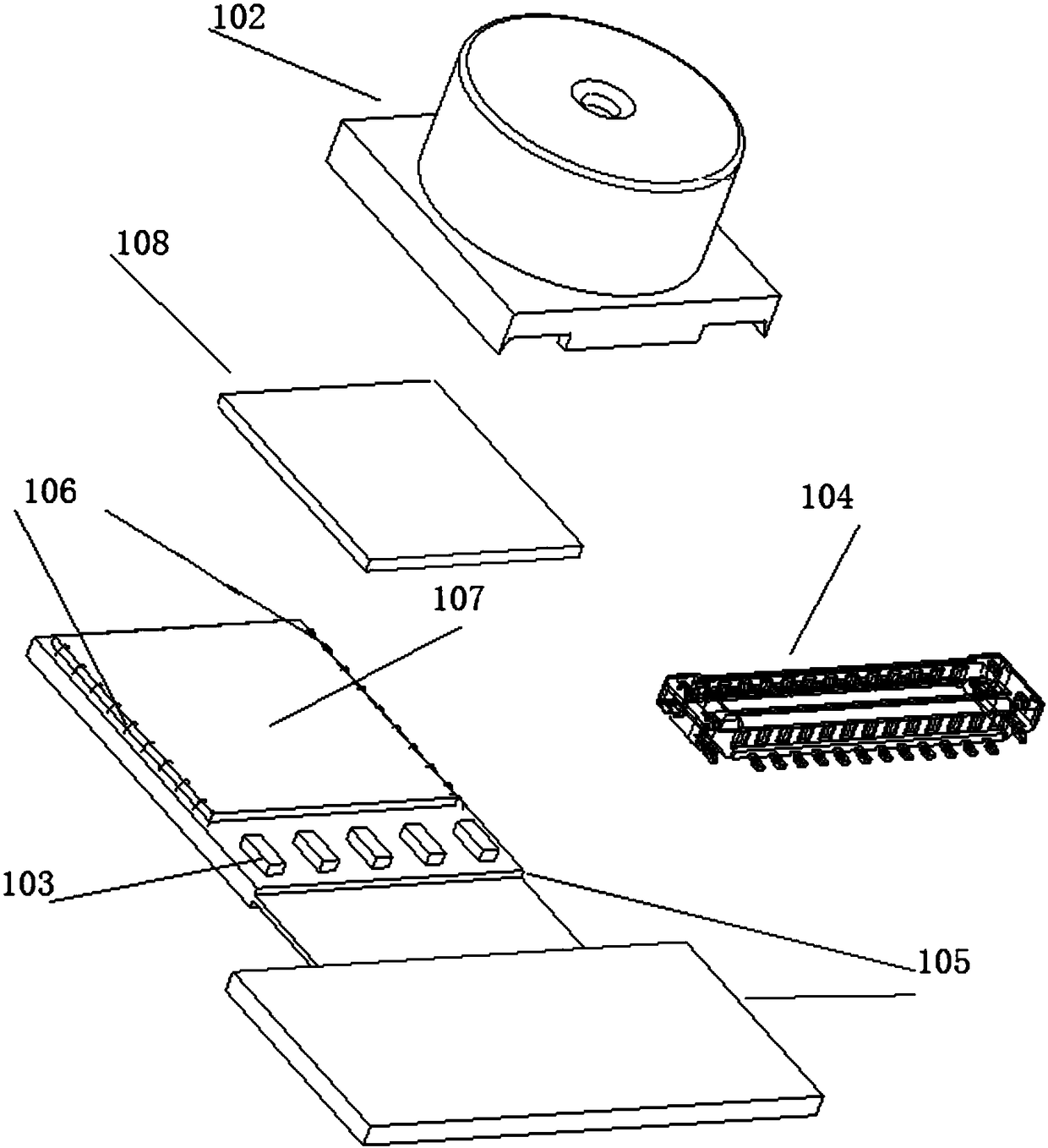

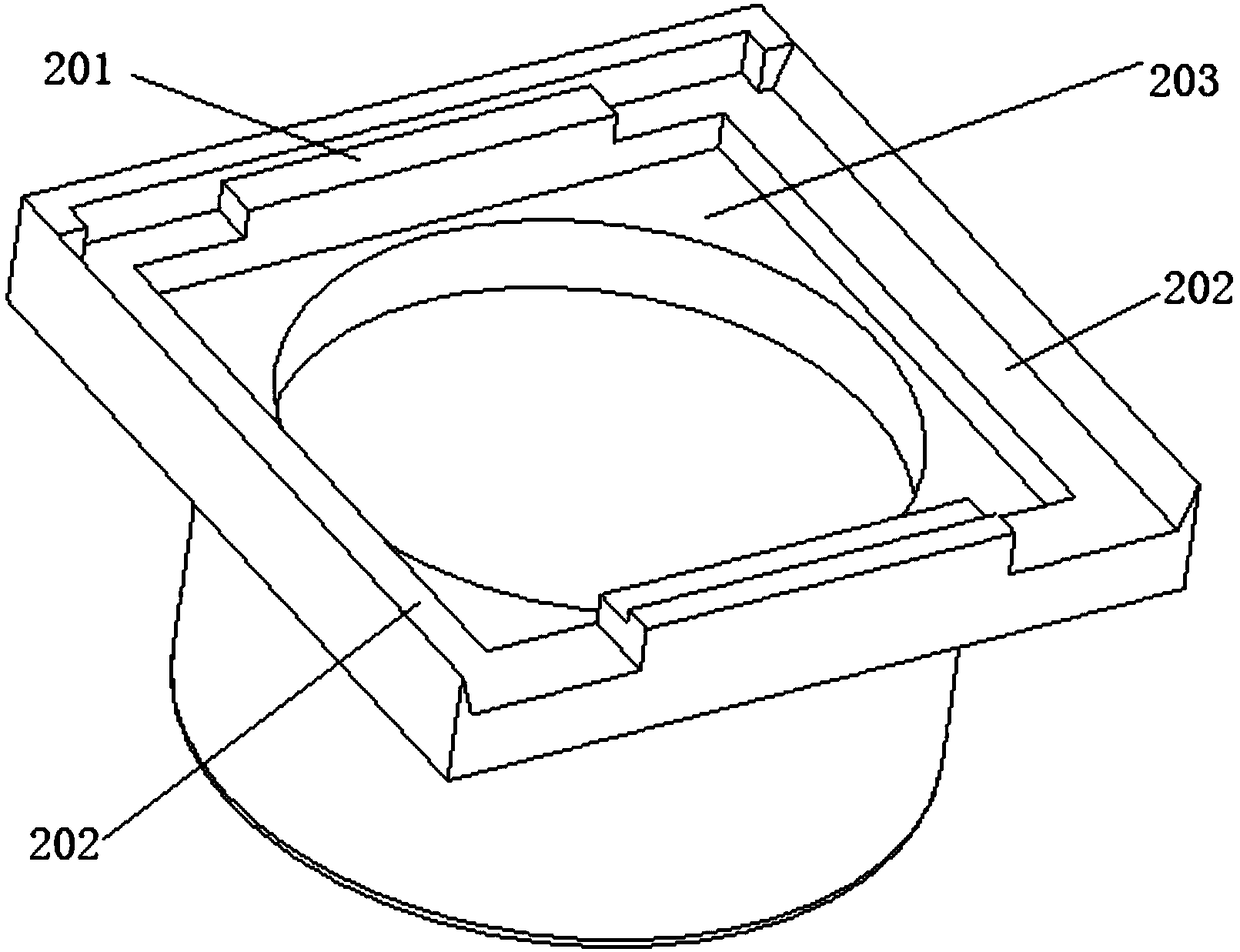

[0022] A camera module, comprising a lens 101, an integrated lens 102, a capacitor 103, a connector 104, a circuit board 105, a gold wire 106, a chip 107, and an optical filter 108, the lens 101 is arranged on the integrated lens 102 Inside. The integrated lens 102 is provided with a lens support part 201 , a space-avoiding part 202 , and a filter support part 203 , and the chip 107 is directly embedded in the lens support part 201 of the inner cavity at the bottom of the integrated lens 102 . The optical filter 108 is directly embedded in the optical filter support portion 203 of the inner cavity at the bottom of the integrated lens 102 .

[0023] The filter 108 , the chip 107 are kept parallel to the integrated lens 102 . The central symmetry axes of the filter 108 , the chip 107 and the integrated lens 102 are coincident.

[0024] The circuit board 105 and the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com