Flatness control process for large-span deck

A flatness and large-span technology, applied to ships and other directions, can solve the problems of difficult overall flatness and precision control, low work efficiency, etc., and achieve the effect of high construction efficiency, low production efficiency, and clear focus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention is further described below in conjunction with specific embodiments:

[0020] A long-span deck flatness control process includes a segmented structure form, a construction process, a precision control method, and deformation correction measures.

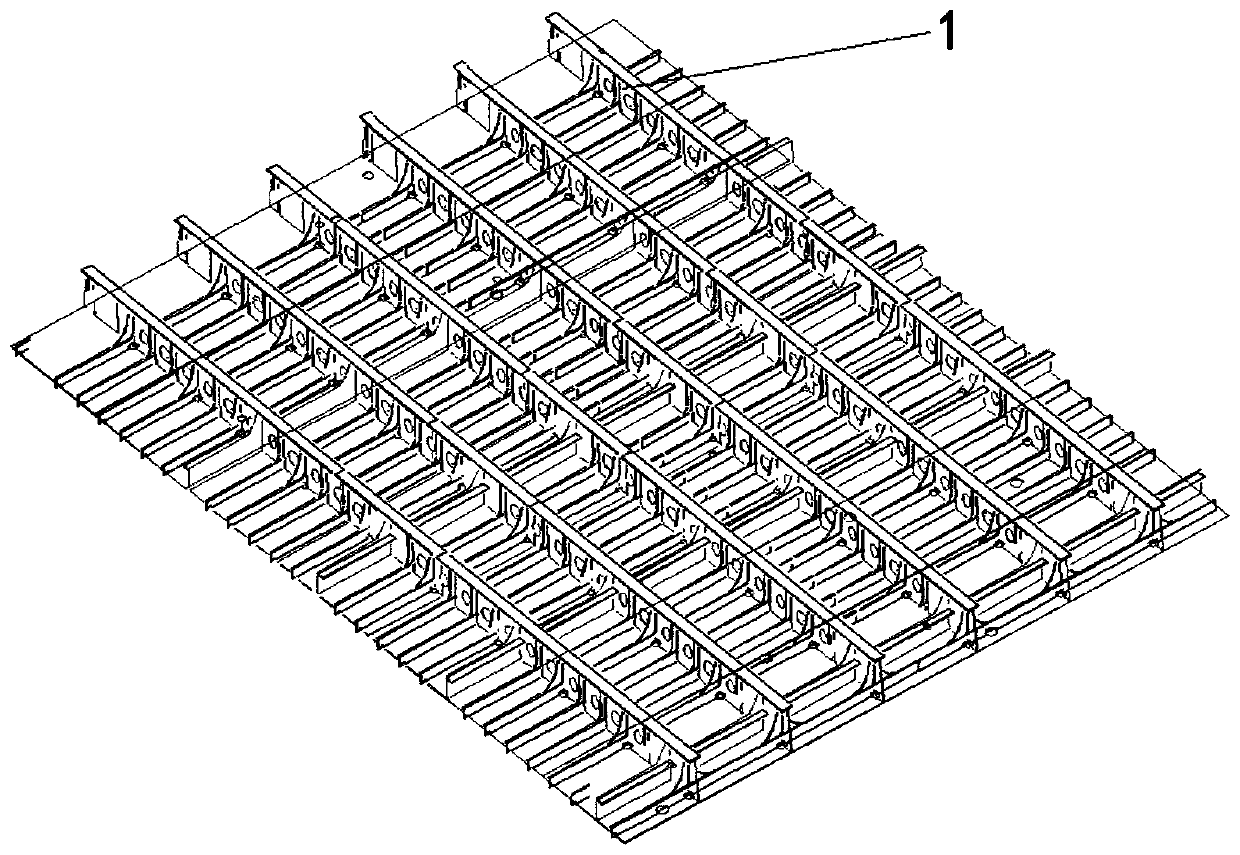

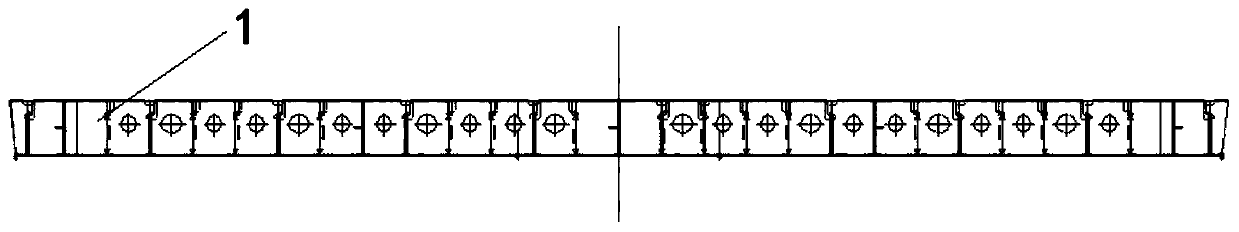

[0021] The segmented structure is aimed at the structural form of the main deck 1 of the ship. The main deck 1 adopts a longitudinal skeleton structure design, and the longitudinal skeleton structure is divided into a longitudinal structure and a transverse structure. The transverse structure uses welded T-profiles with a spacing of 2.4m.

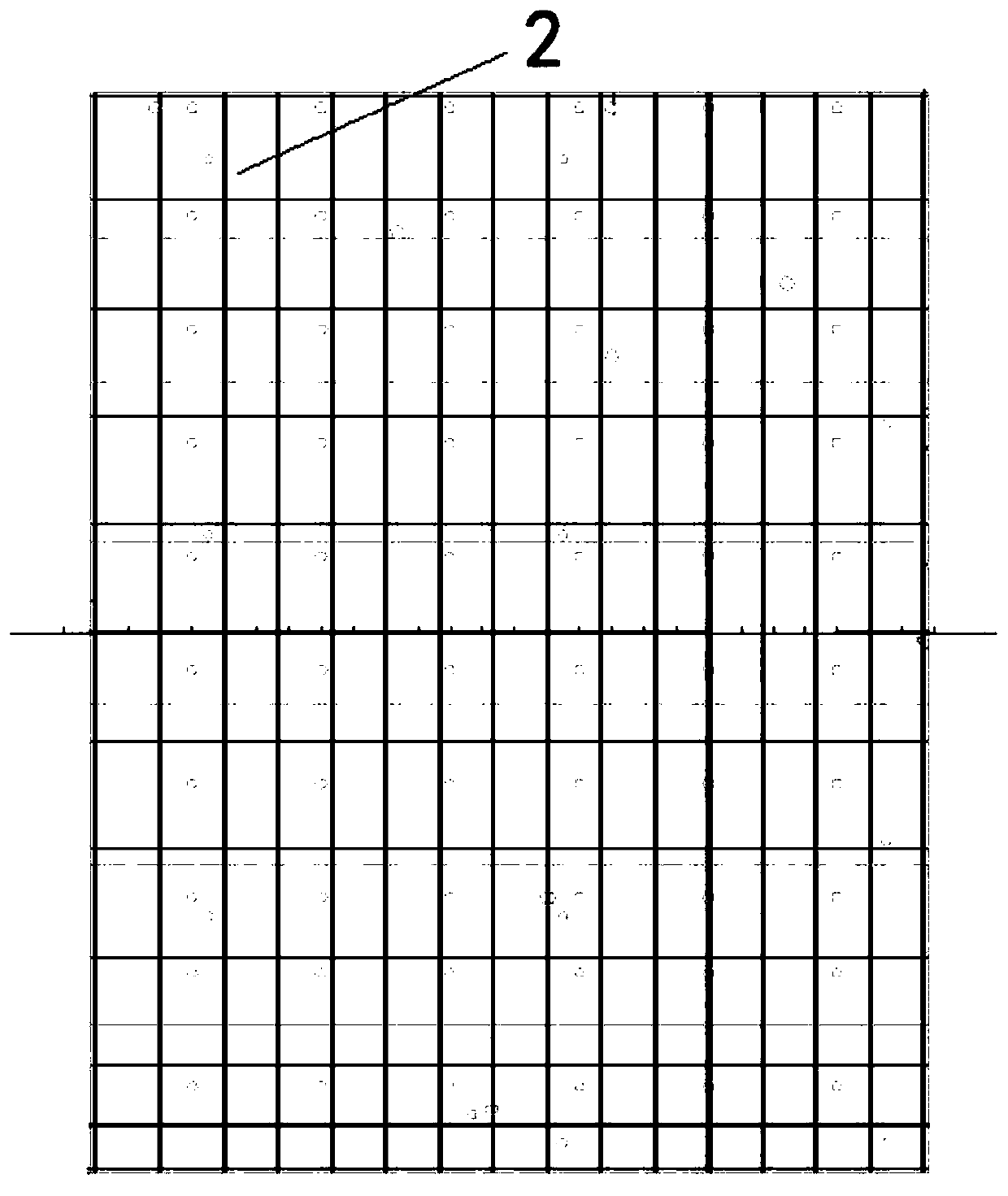

[0022] The construction process includes pre-construction preparation, tire frame 2 manufacturing, main deck 1 planking and welding, frame marking and assembly, frame welding, completion measurement, segmental turning welding, deformation correction, submission for acceptance, and segmental completion barge.

[0023] The truss-type tire frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com