High-radioactive nuclear industry waste microwave heating treatment equipment

A microwave heating and high radioactivity technology, which is applied in the field of microwave heating treatment equipment for high radioactive nuclear industrial waste, can solve the problems of increasing nuclear radiation risk, pipeline blockage, and affecting process efficiency, so as to reduce the risk of being irradiated, improve efficiency, reduce The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

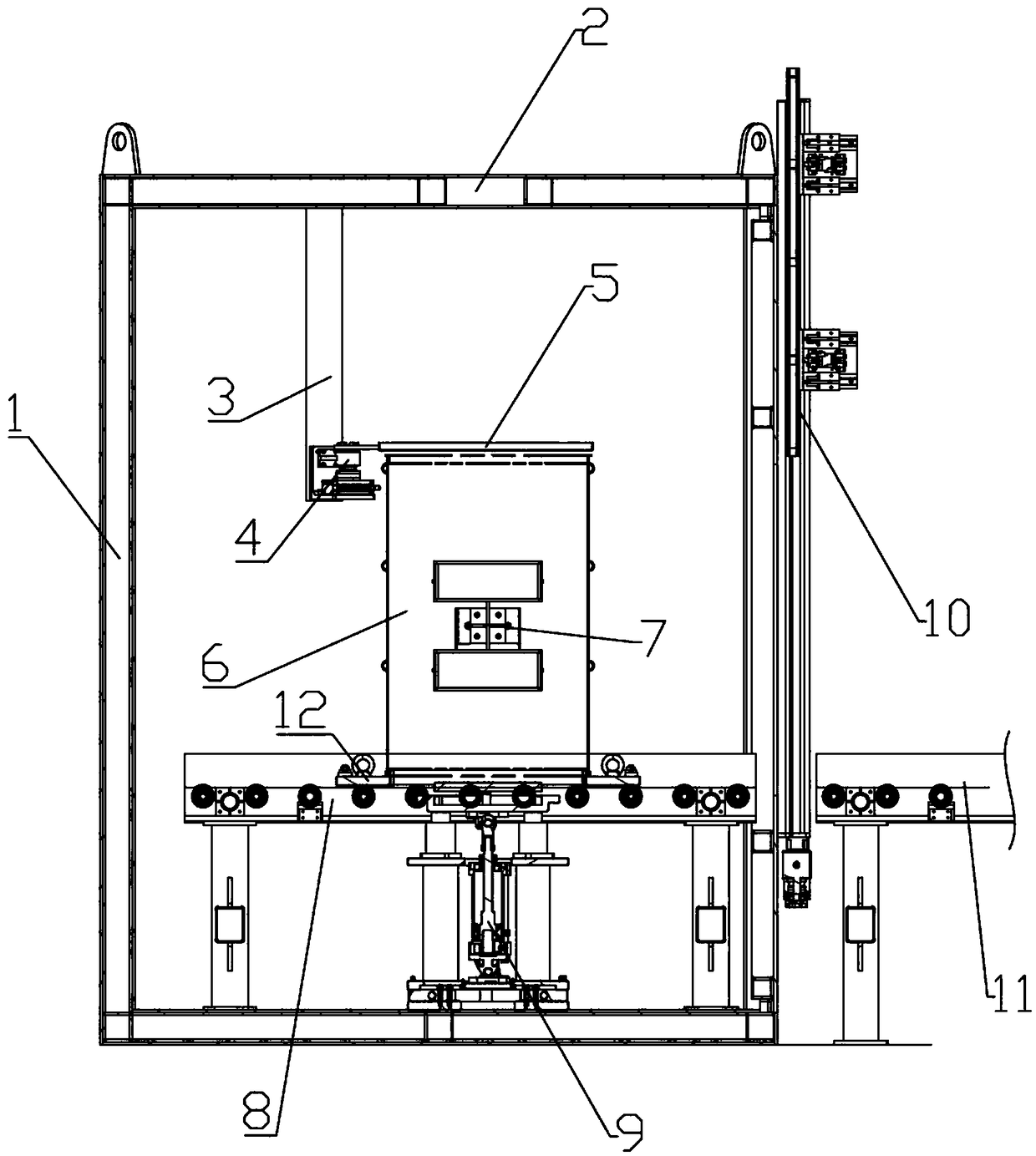

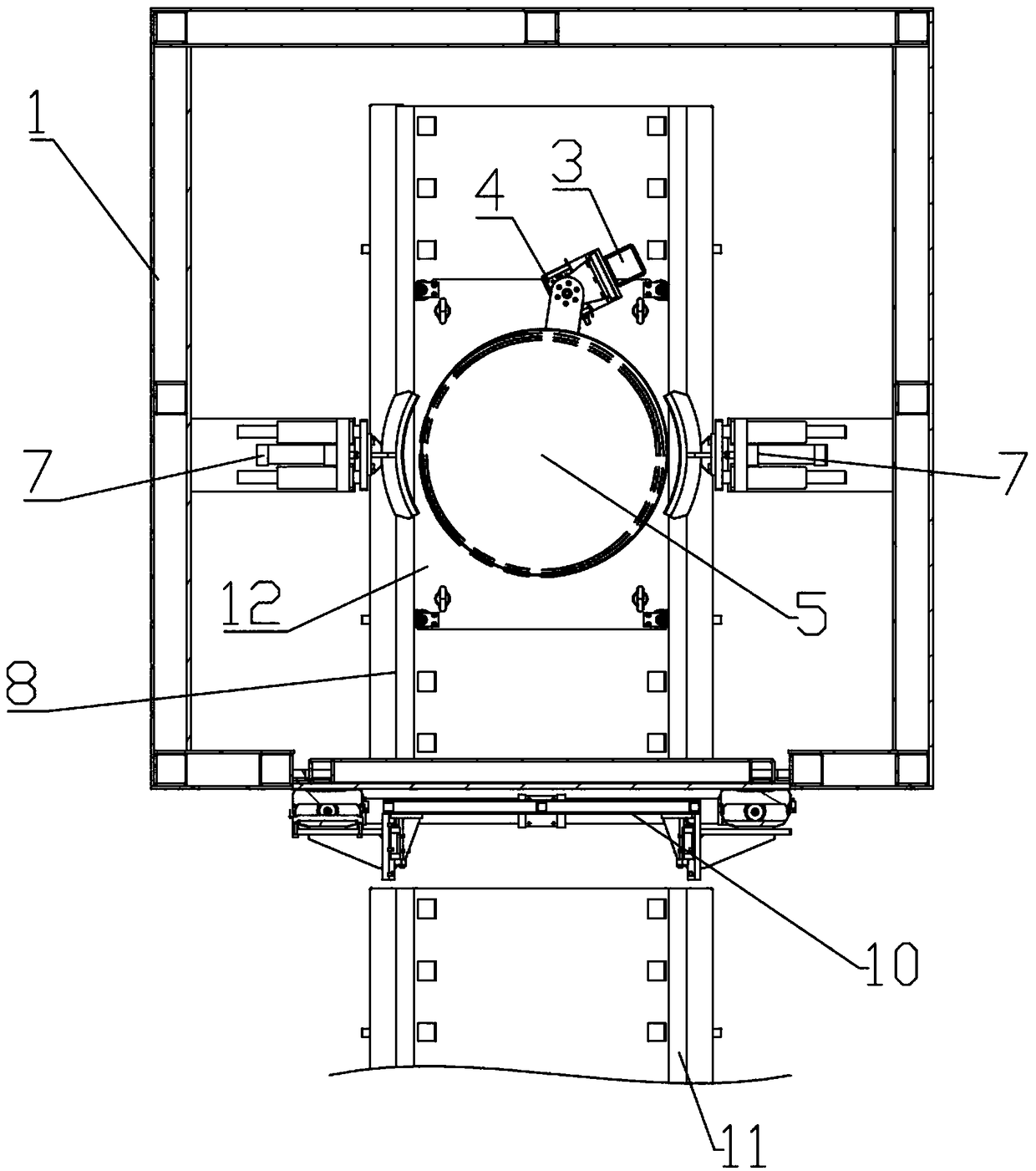

[0050] A microwave heating treatment device for high-radioactive nuclear industrial waste, its structure is as follows figure 1 and figure 2 As shown, it includes a sealed box 1, the top of the sealed box 1 is provided with a microwave heating hole 2 and an exhaust hole for discharging water vapor, a lifting device 9 is arranged below the microwave heating hole 2, and a sealing The door 10, the inside of the sealed box 1 is provided with a transfer device I8 for sending the barrel containing the high-level waste liquid to or from the lifting device 9, and the outside of the sealed box 1 is provided with a transfer device II11, a transfer device I8 and a transfer device The heights of the devices II11 match each other and are located on both sides of the airtight door 10 respectively.

[0051] When it is necessary to heat, evaporate and reduce the volume of the barreled high-level waste liquid, the barrel 6 containing the high-level waste liquid is transported to the sealing ...

Embodiment 2

[0053] On the basis of Embodiment 1, the conveying device I8 and the conveying device II11 are roller conveyors.

[0054] The transfer device I8 is provided with a tray 12 for carrying the bucket 6 containing the high-level waste liquid to move between the transfer device I8 and the transfer device II11.

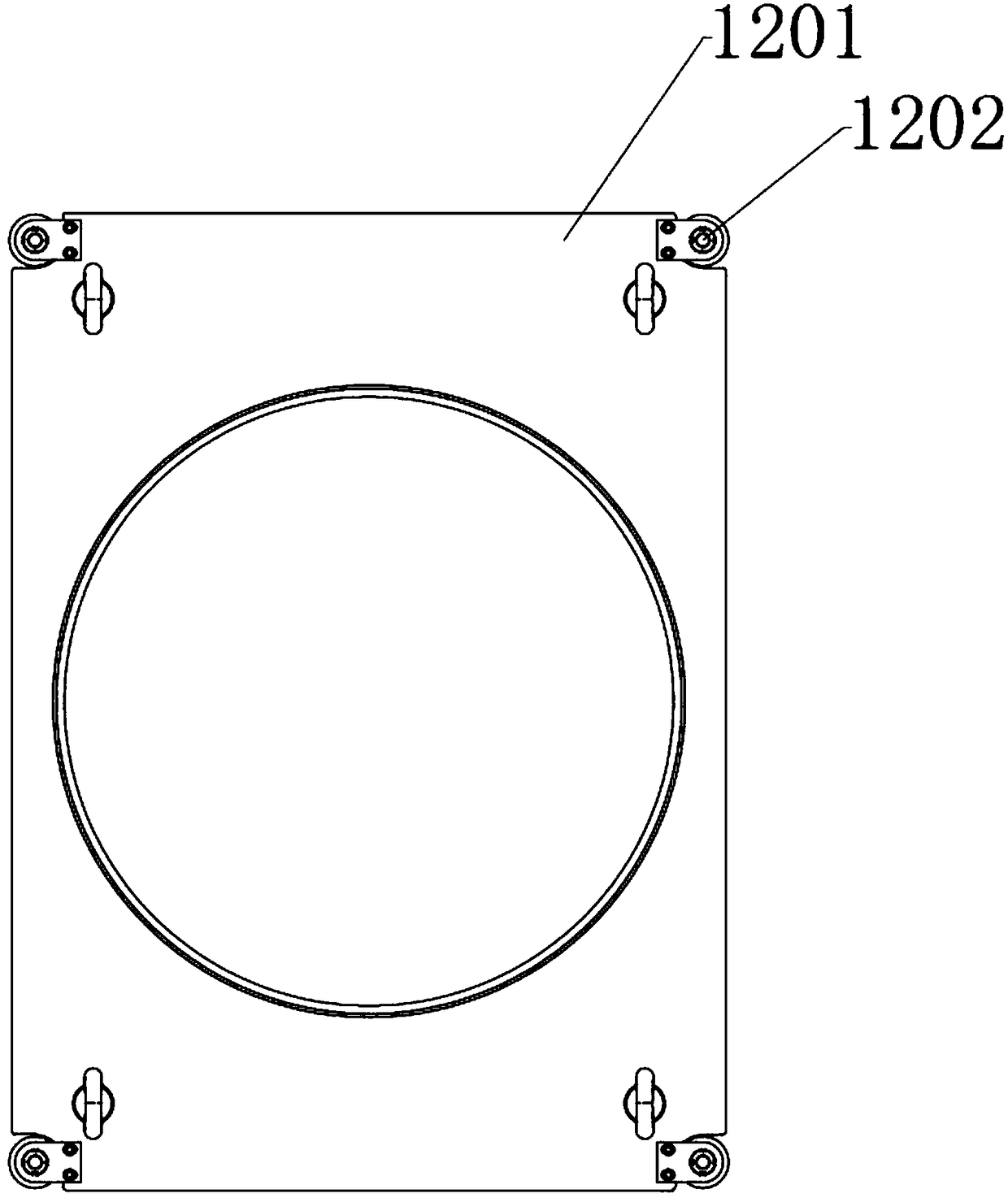

[0055] Tray 12 structure such as image 3 As shown, it includes a tray main body 1201. On both sides of the tray main body 1201, there are at least a pair of rotating assemblies 1202 that can roll relative to the side walls of the conveyor I8 and conveyor II11. The upper surface of the tray body 1201 is provided with a placement part for placing buckets .

[0056] The tray main body 1201 is a rectangular plate made of stainless steel, which has a strong load-carrying capacity and can carry heavy barrels 6 containing high-level waste liquid. The four corners of the tray main body 1201 are provided with arc-shaped notches, each Rotating components 1202 are installed at each ...

Embodiment 3

[0059] On the basis of Embodiment 1, the structure of the airtight door 10 is as follows: Figure 5 and Figure 6 As shown, it includes a large door panel 1006 and a small door panel 1002. The edge of the large door panel 1006 is provided with a plurality of screw holes, and the screw holes are used to fix the large door panel on the door frame 10010. The door frame 10010 is fixedly installed on the box body 1 that needs to be sealed. A sealing strip is arranged between the sealing box body 1 to enhance the sealing performance. The side portions on both sides of the door plate 1006 are respectively provided with a linear sliding mechanism I 1005 parallel to the length direction of the door plate 1006, and the chute of the linear sliding mechanism I 1005 is fixed on the door plate 1006 by screws.

[0060] A plurality of pressing mechanisms 1001 for pressing the small door panel 1002 on the door panel 1006 are connected by screws on the slider of the linear sliding mechanism I1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com