Rapid temperature-reaching and fixing device

A fast, temperature-insulating layer technology, applied in electrical recording, optics, instruments, etc., can solve problems such as long warm-up time, affecting the printing speed of the first page, and poor user experience for users, so as to reduce heat loss, The effect of improving user friendliness and improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

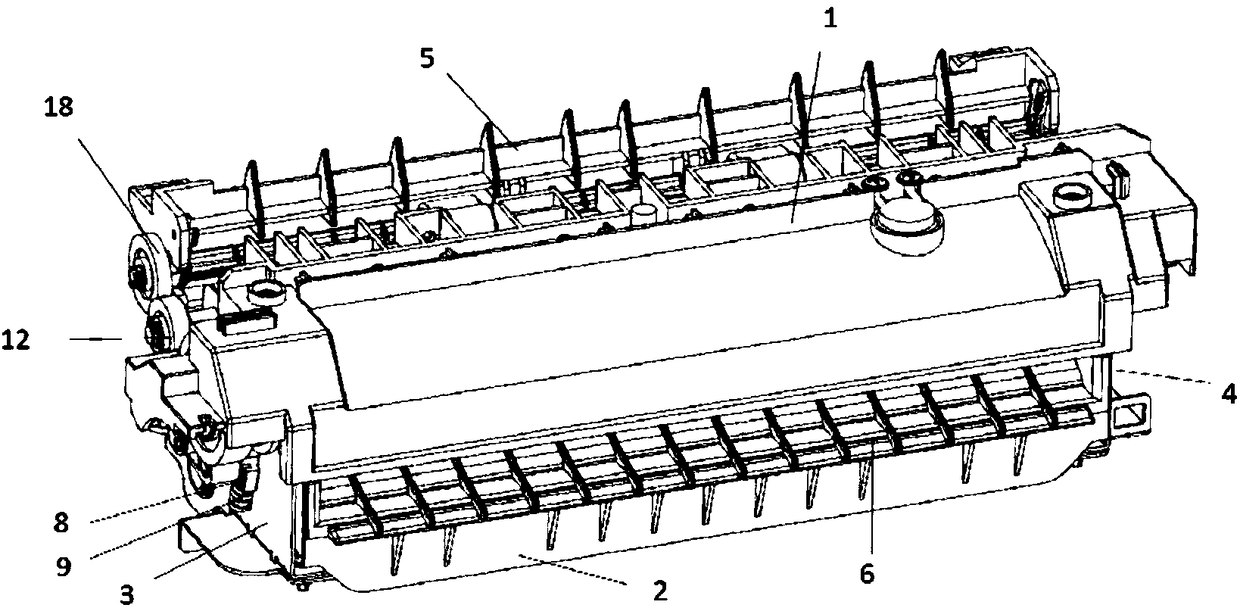

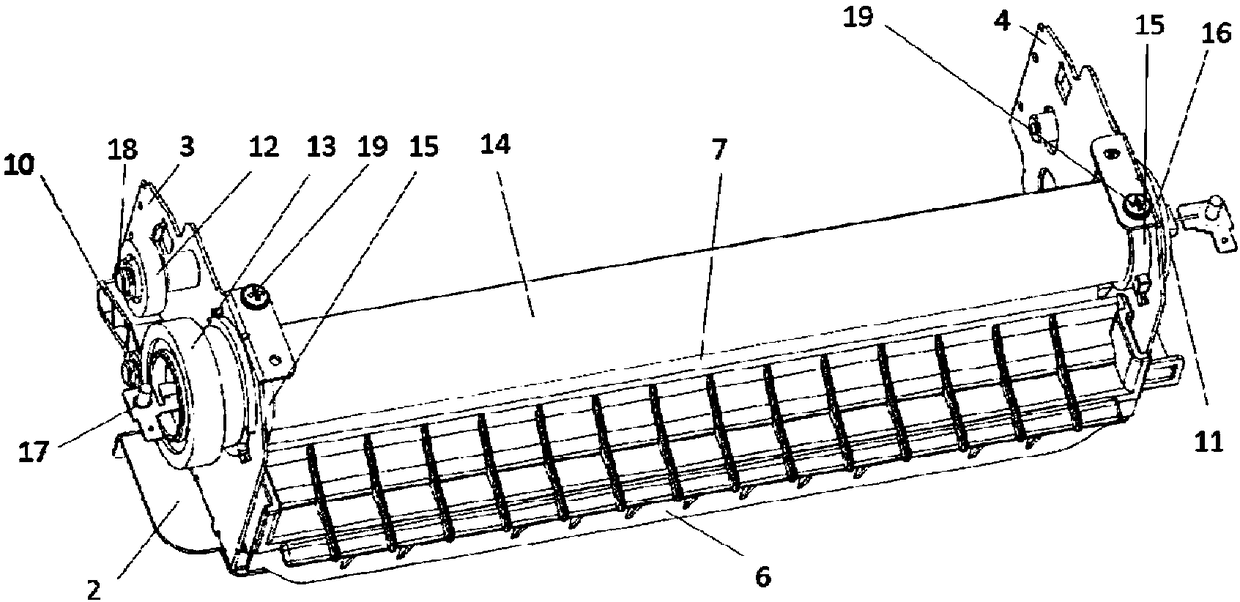

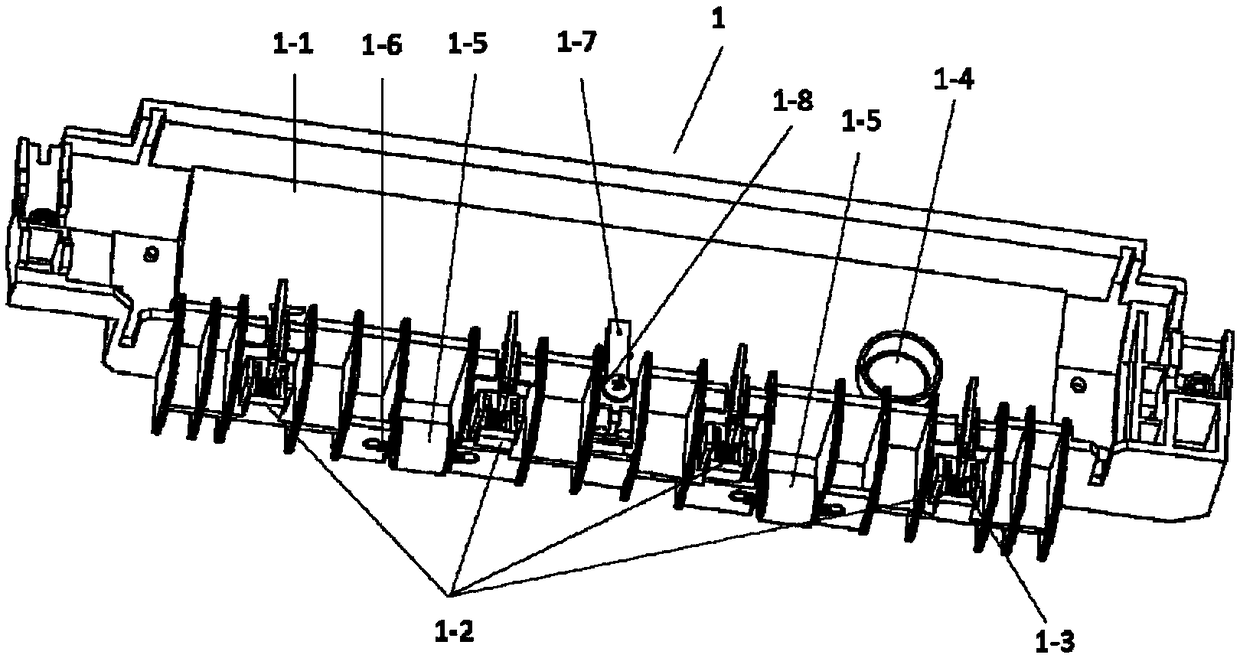

[0104] Such as figure 1 , figure 2 As shown, a fast-to-temperature fixing device in this embodiment includes a thermal insulation fixing upper cover assembly 1, a fixing lower cover 2, a fixing left bracket 3, a fixing right bracket 4, a fixing rear cover assembly 5, a fixing channel frame 6, and a fixing glue Roller 7, fixing rubber roller sleeve 8, fixing rubber roller spring 9, fixing left connecting rod 10, fixing right connecting rod 11, idler wheel 12, heating roller gear 13, heating roller 14, heating roller sleeve 15, heating roller end Cover 16, halogen lamp 17, opening stop ring 18 and self-tapping and self-locking screws 19.

[0105] Such as figure 2 , Figure 13 , Figure 14 and Figure 15 As shown, the fixing left bracket 3 and the fixing right bracket 4 are respectively fixed on both ends of the fixing lower cover 2, wherein the positioning structures 3-1 and 4-1 under the fixing left bracket 3 and the fixing right bracket 4 are respectively inserted into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com