Real-time fixed-position material level detection system

A material level detection and detection board technology, used in measuring devices, liquid/fluid solids measurement, liquid level indicators for physical variable measurement, etc. Accurate measurement results, excellent sealing effect and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

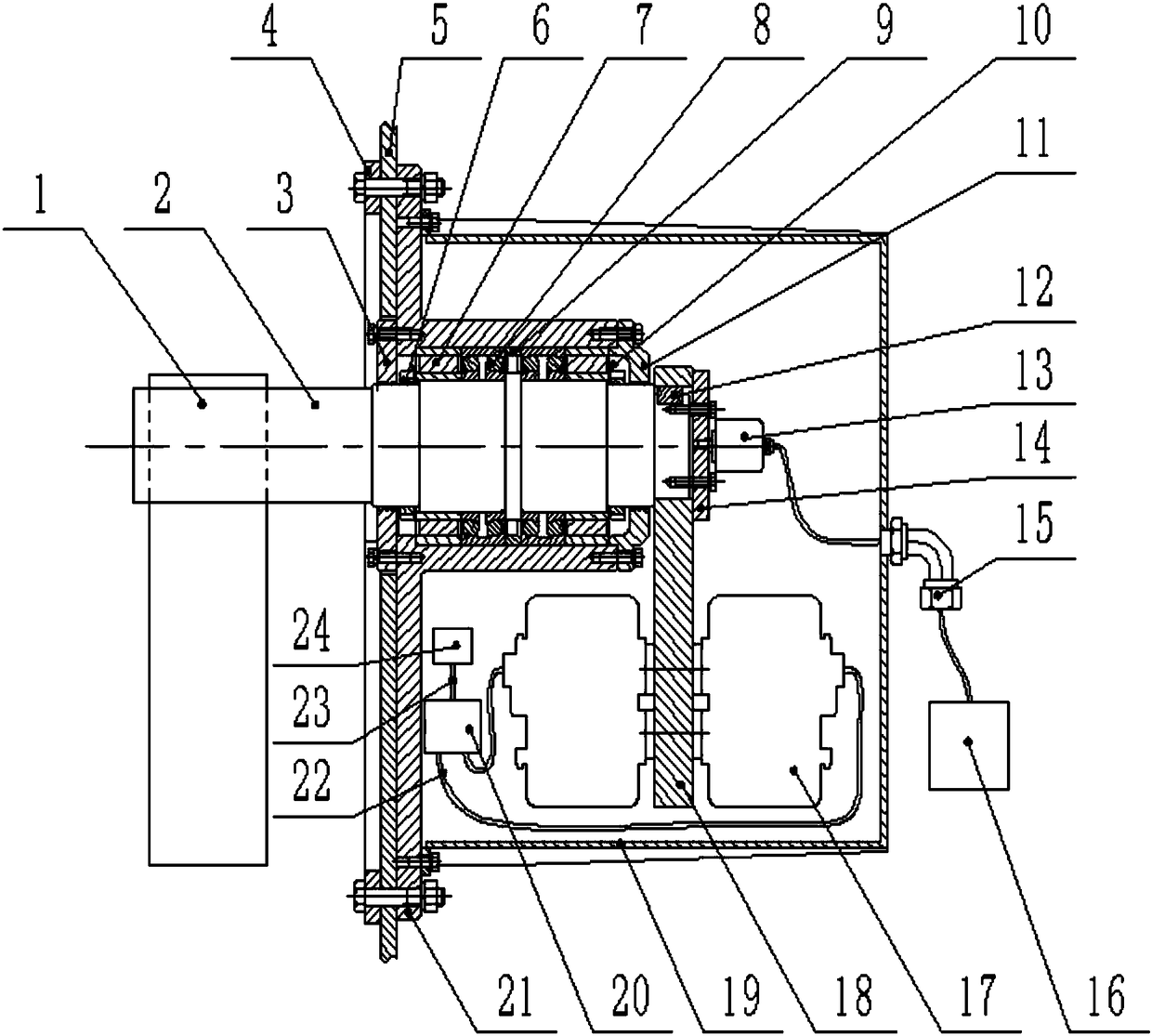

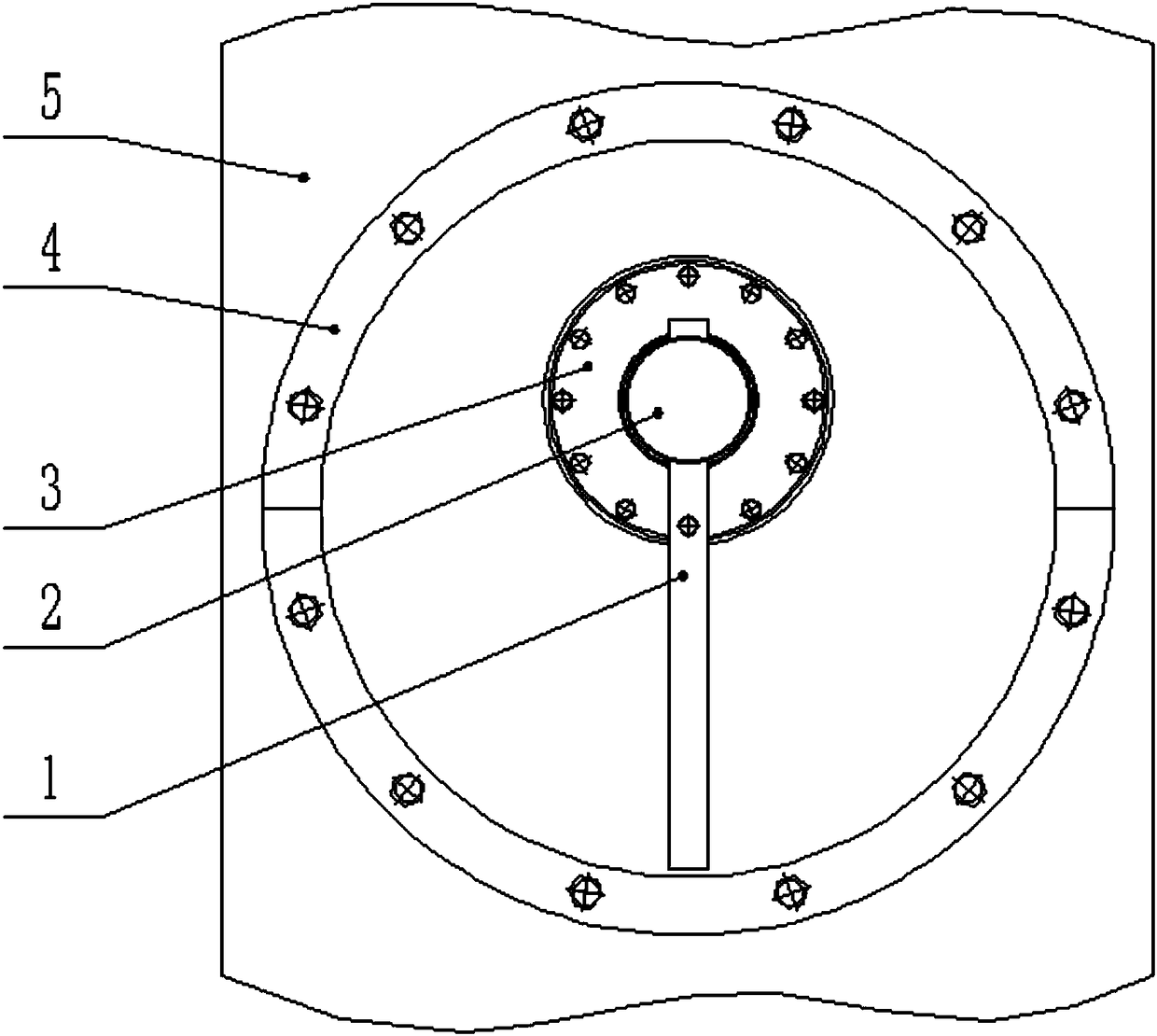

[0015] Such as figure 1 , 2 As shown, a real-time fixed-point material level detection system includes a detection board (1), a transmission shaft (2), a support device, a drive device, a signal acquisition and display device, and a sealing device. The support device includes: bearing seat (21), rubber bearing (7), spherical roller bearing (8), spacer ring (9), round nut (6), stop washer (10) and bearing gland ( 11); the driving device includes: an encoder (24), a frequency modulator (20), an oscillator (17), a mounting plate (18) and a shaft end gland (14); the signal acquisition and display device consists of an angle It consists of a displacement signal collector (13) and a display (16); the sealing device includes: a labyrinth cover (3) and a protective cover (19).

[0016] The detection plate (1) is made of stainless steel and welded to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com