Turbulence structure in array jet cooling

A technology of array jets and jets, which is applied to the supporting elements of blades, engine elements, machines/engines, etc., can solve the problem of unsatisfactory improvement of heat exchange effect, uneven cooling effect of target plate, uneven heat exchange of impacting target plate, etc. problems, to achieve the effect of simple manufacturing process, low flow resistance loss, and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The invention will be described in further detail below in conjunction with the accompanying drawings and specific examples, but the present invention is not limited to the following examples.

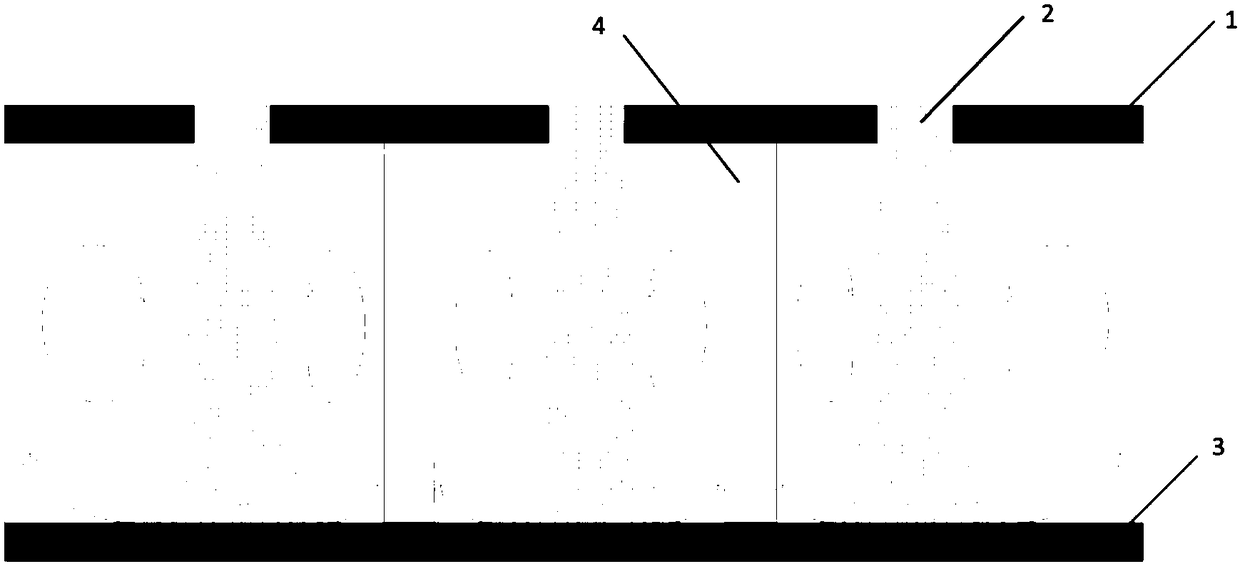

[0034] refer to figure 1 , a highly efficient spoiler column structure in array jet cooling, comprising a jet orifice plate 1 and a jet target plate 3, the jet orifice plate 1 is provided with a plurality of impact holes 2 arranged in an array; the jet orifice plate 1 is located in the The upper part of the jet target plate 3 is designed as a cavity between the two, and the spoiler column 4 is arranged on the jet target plate 3 . In this scheme, the diameter of the impact hole 2 is set to D.

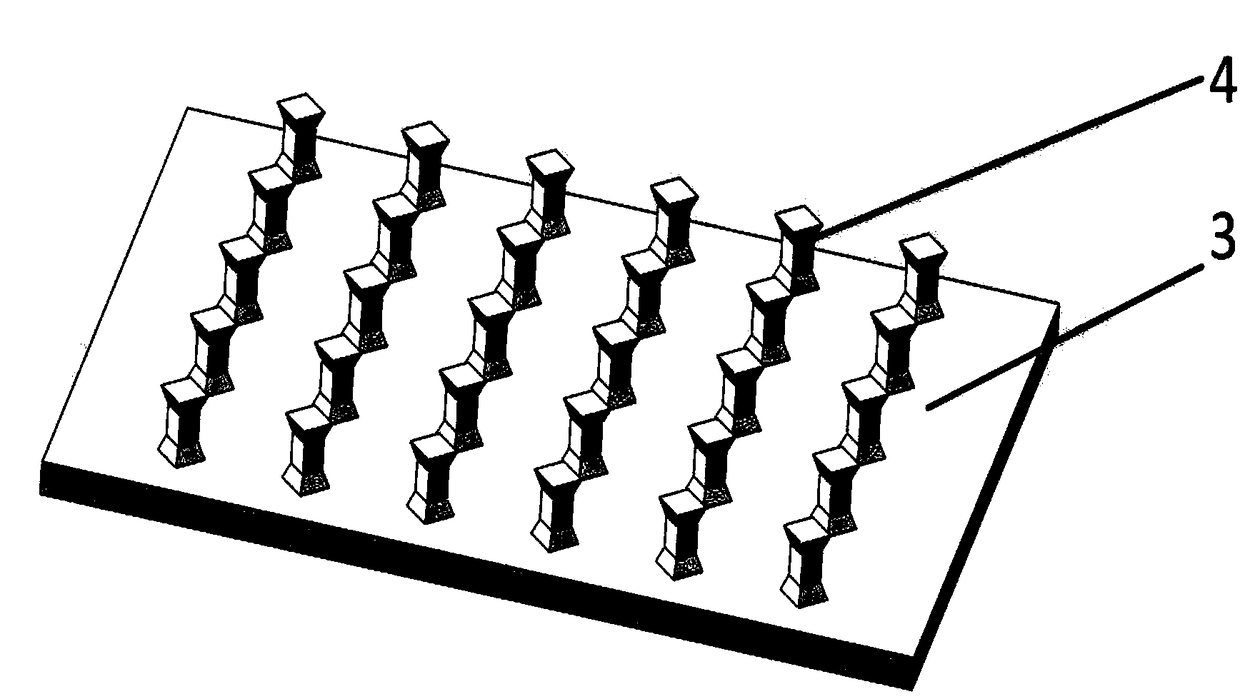

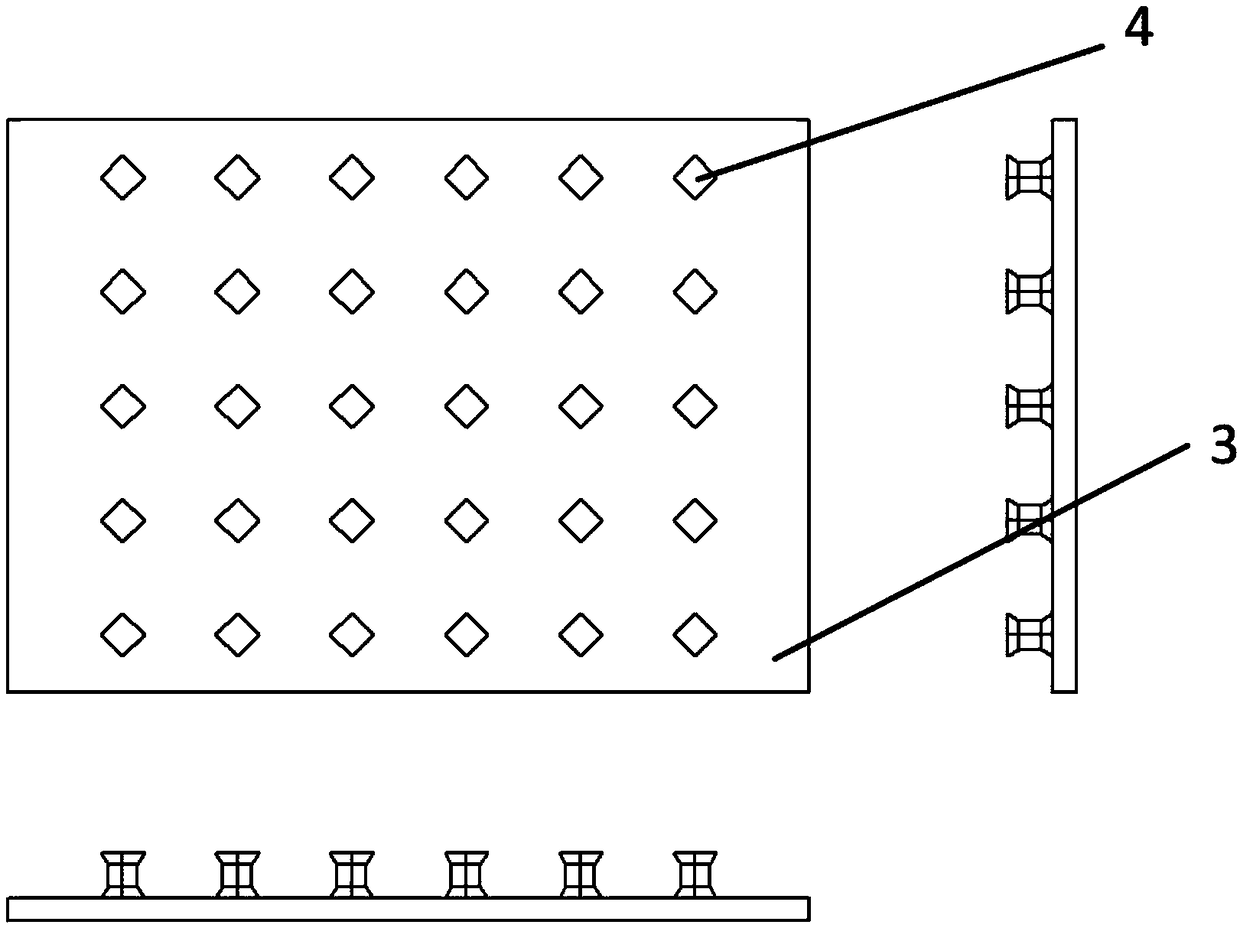

[0035] As a scheme improvement, refer to figure 2 and image 3 , the spoiler column 4 is a quadrangular prism design, and the spoiler column of the quadrangular prism design is divided into upper, middle and lower parts. The top angle is 90°, the side length of the bottom surface is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com