Combined cutting PDC drill bit with spin-tunneling tooth structure

A technology of spin drilling teeth and compound cutting, which is applied in construction and other fields, can solve the problems of early failure efficiency of drill bits and slow drilling speed, and achieve the effect of improving drilling efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

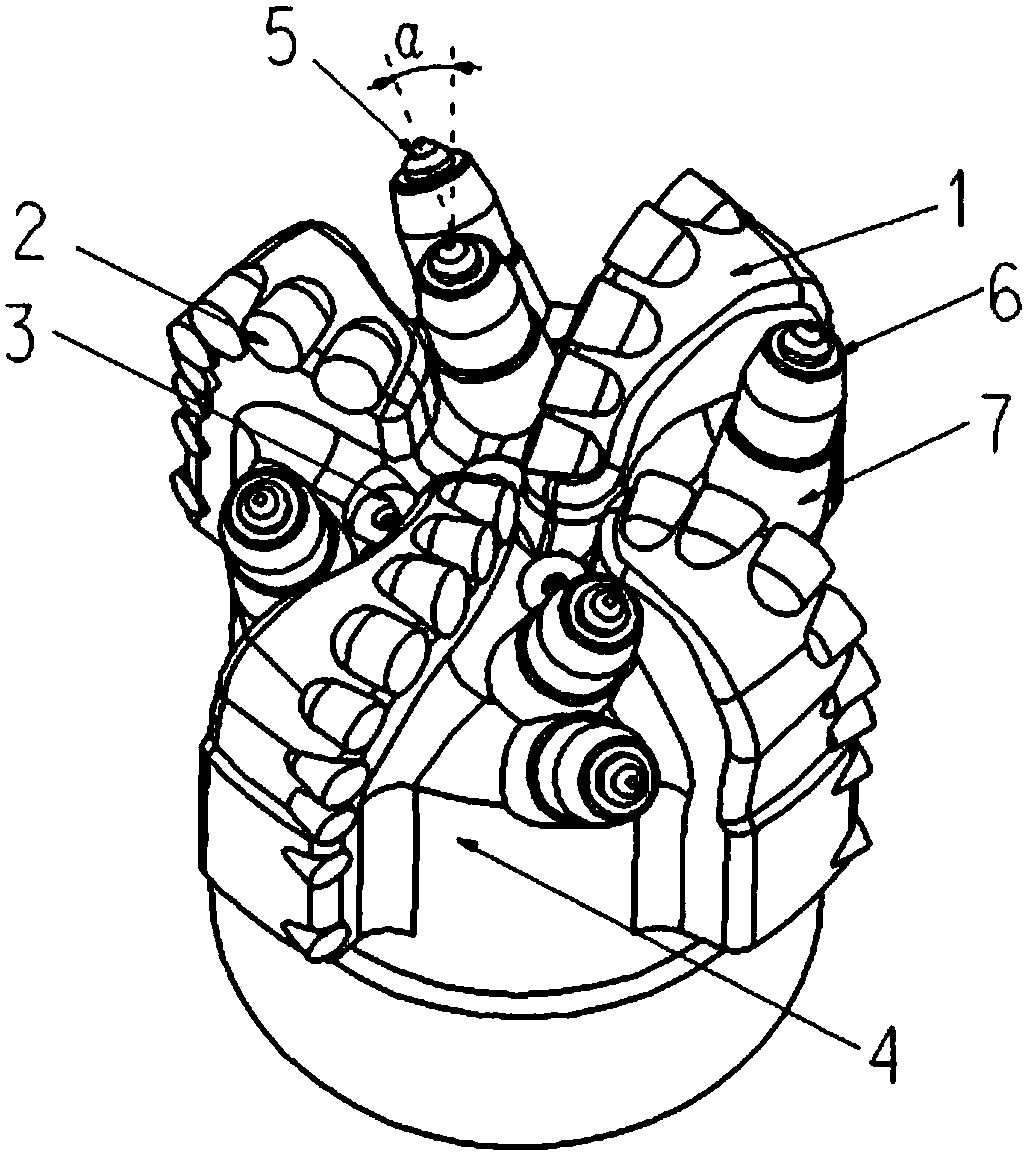

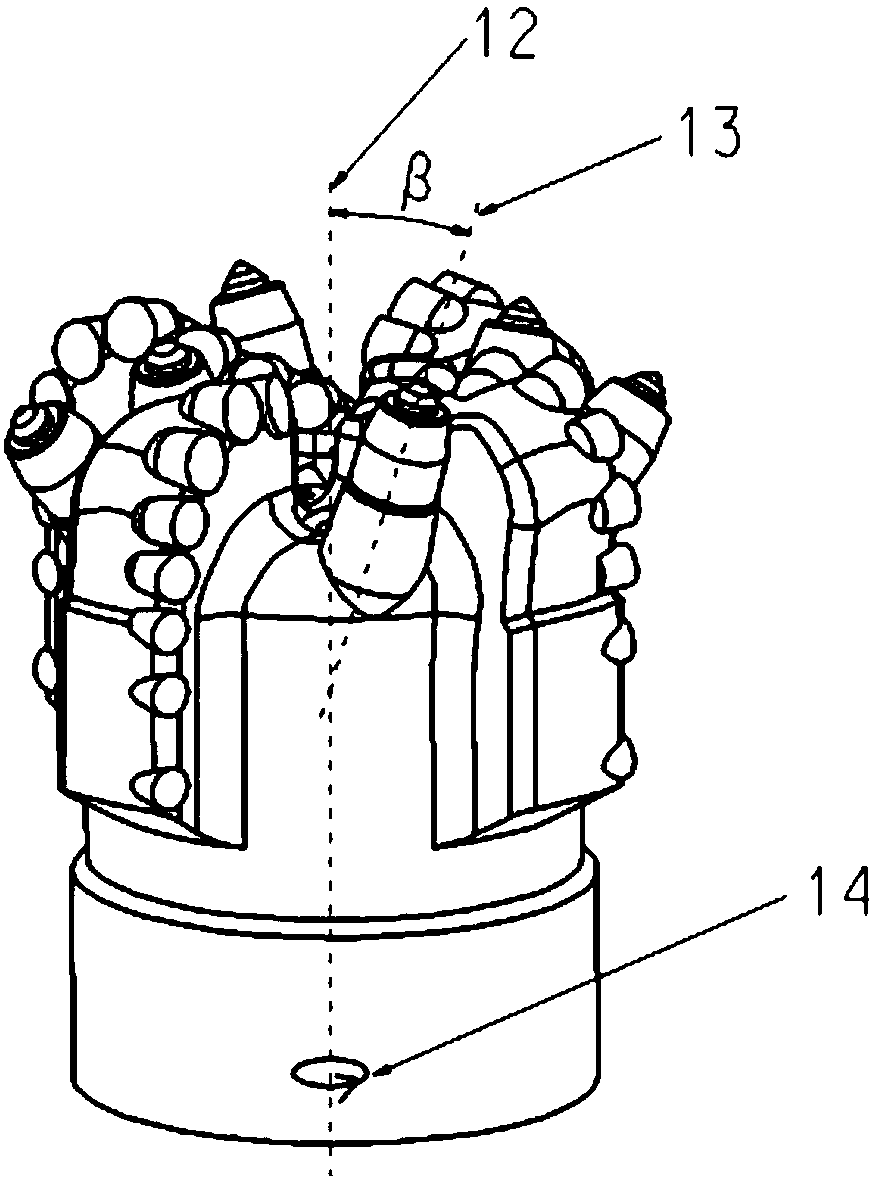

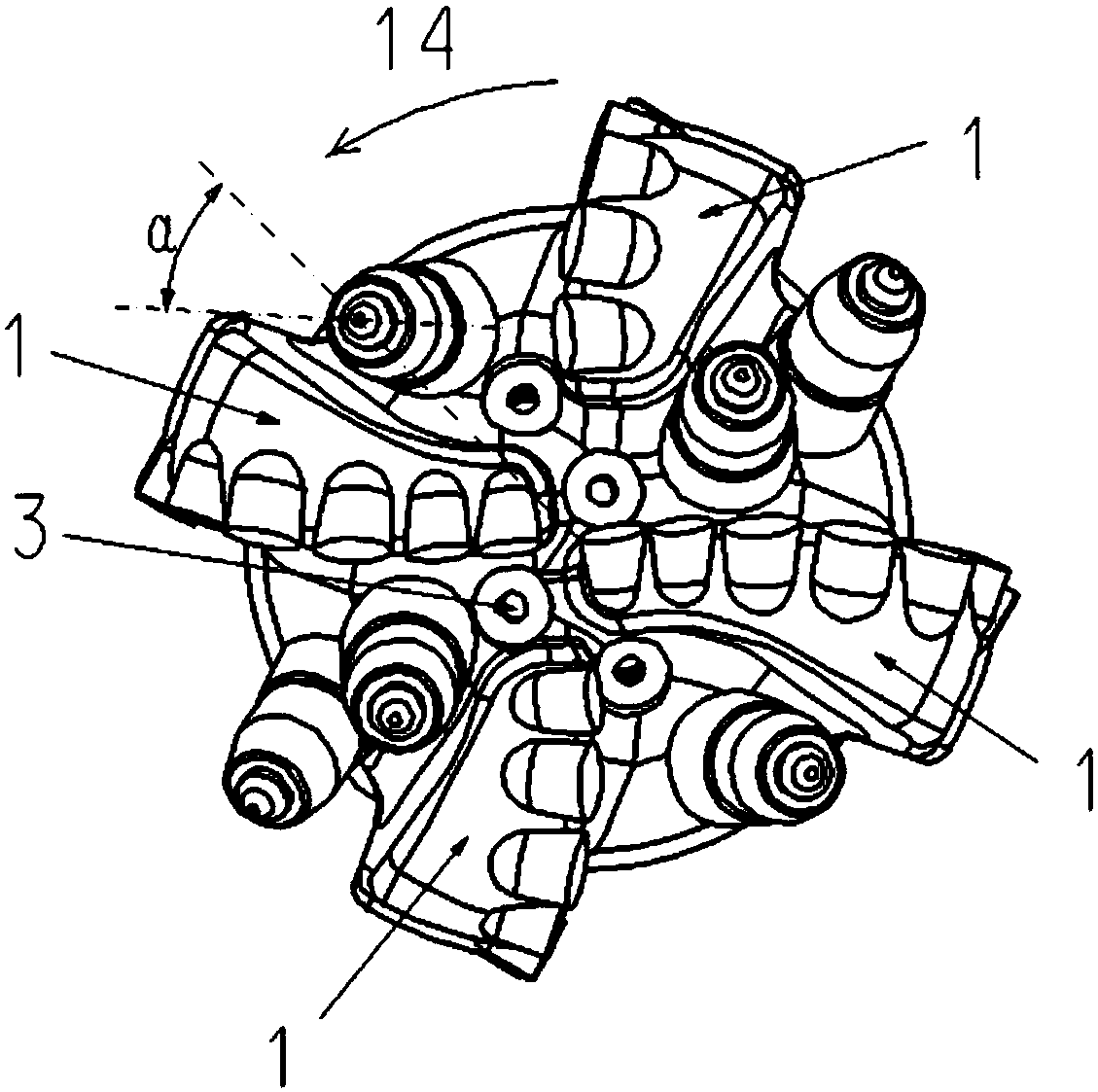

[0037] see figure 1 , shows the overall schematic diagram of one embodiment of the compound cutting PDC drill bit with spin driving tooth structure described in the present invention.

[0038] Wherein, the front end of the drill bit is provided with a plurality of drill blade blades 1, an outer flow channel 4 is arranged between the drill blade blades, and a plurality of PDC main cutters 2 for cutting formation rocks are arranged on each drill blade blade 1, so The drill bit can also be provided with a plurality of nozzles 3 between two drill bit blades 1, so that the drilling fluid can be sprayed out through the nozzles 3 and flow into the annular sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com