Linkage locking anti-rebounding civil defense door utilizing fluid pressure

A fluid pressure, civil air defense door technology, applied to non-mechanical transmission-operated locks, building locks, door/window accessories, etc. Stable and reliable, good synchronization, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

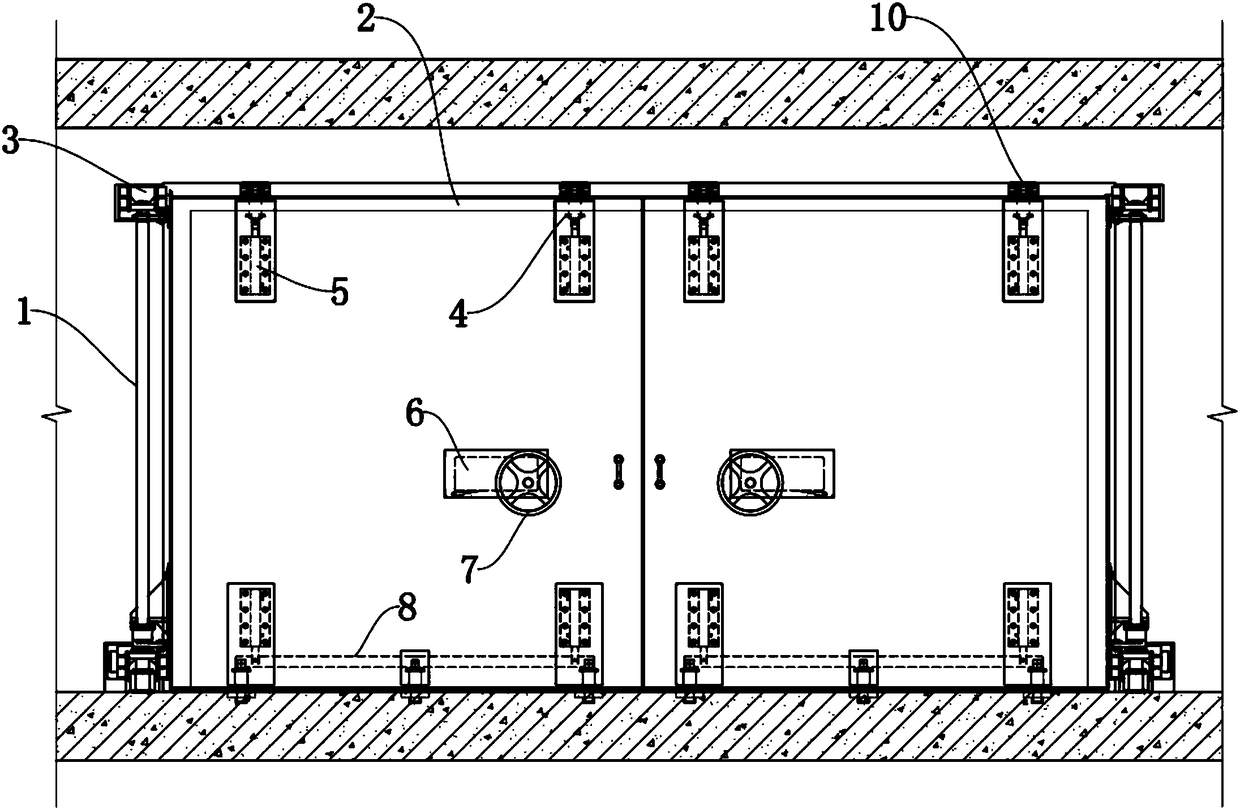

[0040] Such as figure 1 , figure 2 As shown, this embodiment discloses a linkage locking anti-rebound civil air defense door using fluid pressure, including a door frame 1, a door leaf 2, a fluid pressure system arranged on the door leaf 2, and a lock head 4 for switching.

[0041]The door frame 1 is fixed on the wall, and the door leaf 2 is connected to the door frame 1 through the hinge 3. The fluid pressure system includes a pump 6, a reversing valve 12, pipelines and multiple synchronously operating double-acting pressure cylinders 5, and the pump 6 communicates with Reversing valve 12. The reversing valve 12 communicates with the double-acting pressure cylinder 5 through a pipeline; the double-acting pressure cylinder 5 includes a cylinder body and a piston rod, and the cylinder body is fixed on the door leaf 2 or in the door leaf 2 through the cylinder seat 501; the lock head 4 is connected with the double-acting pressure cylinder 5. The lock head 4 includes a lock bo...

Embodiment 2

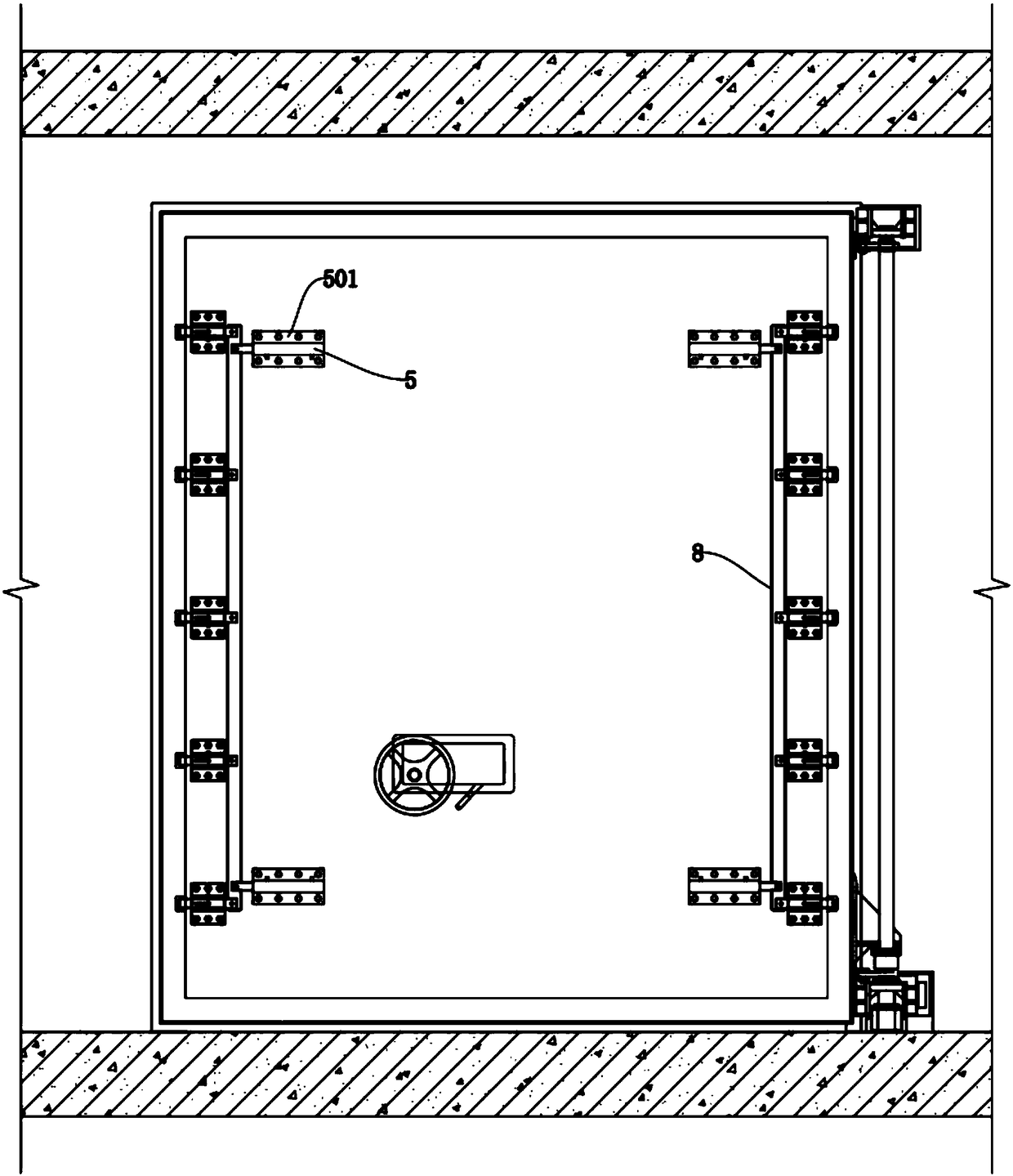

[0052] Such as image 3 As shown, this embodiment discloses a linkage locking anti-rebound civil air defense door utilizing fluid pressure, including a door frame 1, a door leaf 2 arranged in the door frame 1, a fluid pressure system arranged on the door leaf 2 and a lock head for switching 4.

[0053] The structure and connection relationship of each part in this embodiment are the same as in Embodiment 1, the difference is:

[0054] In this embodiment, the double-acting pressure cylinder 5 is arranged horizontally, the piston rod corresponds to the lateral movement, the lock head 4 connected to the double-acting pressure cylinder 5 is arranged horizontally, and the lock cylinder 402 corresponds to the lateral movement. Two double-acting pressure cylinders 5 are respectively arranged on the left and right sides of the door leaf 2, and a reinforcing plate is arranged between the double-acting pressure cylinder 5 and the door leaf 2, and the double-acting pressure cylinder 5, ...

Embodiment 3

[0057] Such as Figure 4 As shown, this embodiment discloses a linkage locking anti-rebound civil air defense door utilizing fluid pressure, including a door frame 1, a door leaf 2 arranged in the door frame 1, a fluid pressure system arranged on the door leaf 2 and a lock head for switching 4.

[0058] The structure and connection relationship of each part in this embodiment are the same as in Embodiment 1, the difference is:

[0059] In this embodiment, the lock core 402 and the piston rod are connected through a shaft-hole matching structure, and fastening bolts are provided at the connection for fastening. In this matching structure, the lock core 402 is provided with a hole, the end of the piston rod is provided with a shaft that fits into the hole, and the lock core 402 is provided with a screw hole communicating with the hole, and the fastening bolt is located in the screw hole and press against the shaft; or the end of the lock cylinder 402 is provided with a shaft, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com