Preparation method and application of low temperature resistance type shear thickening fluid

A low-temperature-resistant, liquid-resistant technology, applied in the field of low-temperature-resistant materials, can solve the problems of failure of shear thickening behavior and limit the application range of shear thickening liquid, and achieve the effect of stable solution, large flexibility and small thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

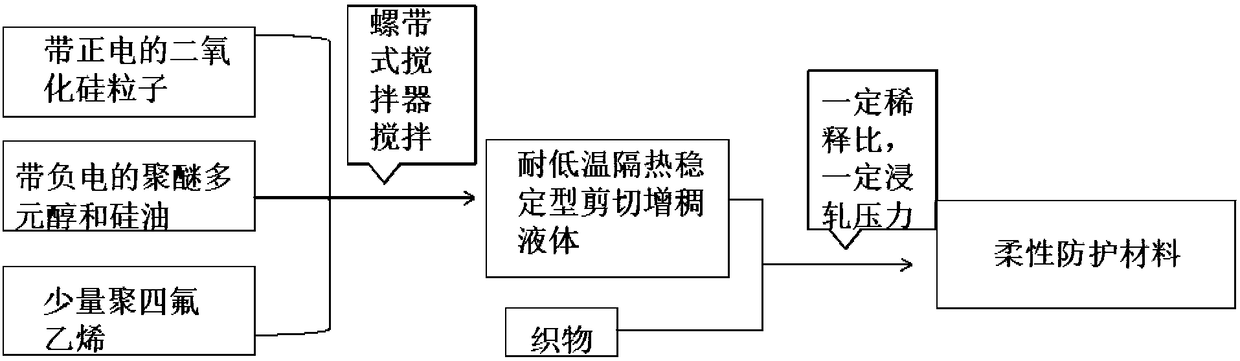

Method used

Image

Examples

Embodiment 1

[0022] A kind of preparation method of low temperature resistance type shear thickening liquid, described preparation method comprises the following steps:

[0023] (1) Add 80 parts of a mixture of polyether polyol 8000 and 20 parts of silicone oil containing 0.01% of anionic surfactant AS-1, and 2 parts of polytetrafluoroethylene into a three-necked flask, mix well, and prepare a mixed dispersion medium;

[0024] (2) 300 parts of SiO with a particle size of 20nm 2 Put the particles in a 1000mL four-necked flask, add 250mL anhydrous toluene and 5mL 3-aminopropyltrioxymethylsilane, and mix them ultrasonically for 30 minutes, reflux at 110°C, and magnetically stir for 24 hours; , ethanol, acetone repeatedly washed; then vacuum-dried at 50°C to obtain positively charged micro-nano spherical silica particles;

[0025] (3) Add the positively charged micro-nano spherical silica particles prepared in step (2) into the mixed dispersion medium prepared in step (1), and use a ribbon s...

Embodiment 2

[0028] A kind of preparation method of low temperature resistance type shear thickening liquid, described preparation method comprises the following steps:

[0029] (1) Add 60 parts of a mixture of polyether polyol 8000 and 40 parts of silicone oil containing 0.01% of anionic surfactant AS-1, and 2 parts of polytetrafluoroethylene into a three-necked flask, mix well, and prepare a mixed dispersion medium;

[0030] (2) 400 parts of SiO with a particle size of 20nm 2 Put the particles in a 1000mL four-necked flask, add 250mL anhydrous toluene and 5mL 3-aminopropyltrioxymethylsilane, and mix them ultrasonically for 30 minutes, reflux at 110°C, and magnetically stir for 24 hours; , ethanol, acetone repeatedly washed; then vacuum-dried at 50°C to obtain positively charged micro-nano spherical silica particles;

[0031] (3) Add the positively charged micro-nano spherical silica particles prepared in step (2) into the mixed dispersion medium prepared in step (1), and use a ribbon s...

Embodiment 3

[0034] A kind of preparation method of low temperature resistance type shear thickening liquid, described preparation method comprises the following steps:

[0035] (1) Add 50 parts of a mixture of polyether polyol 8000 and 50 parts of silicone oil containing 0.01% of anionic surfactant AS-1, and 2 parts of polytetrafluoroethylene into a three-necked flask, mix well, and prepare a mixed dispersion medium;

[0036] (2) 480 parts of SiO with a particle size of 20nm 2 Put the particles in a 1000mL four-necked flask, add 250mL anhydrous toluene and 5mL 3-aminopropyltrioxymethylsilane, and mix them ultrasonically for 30 minutes, reflux at 110°C, and magnetically stir for 24 hours; , ethanol, acetone repeatedly washed; then vacuum-dried at 50°C to obtain positively charged micro-nano spherical silica particles;

[0037] (3) Add the positively charged micro-nano spherical silica particles prepared in step (2) into the mixed dispersion medium prepared in step (1), and use a ribbon s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com