Printing ink as well as preparation method and application thereof

A technology for printing ink and diluent, applied in the field of printing ink, can solve the problems of difficult-to-adhesion layer, affecting the dust removal efficiency of an electrostatic dust collection module, and damage to the ink layer, and achieves the effects of fast drying speed, good viscoelasticity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

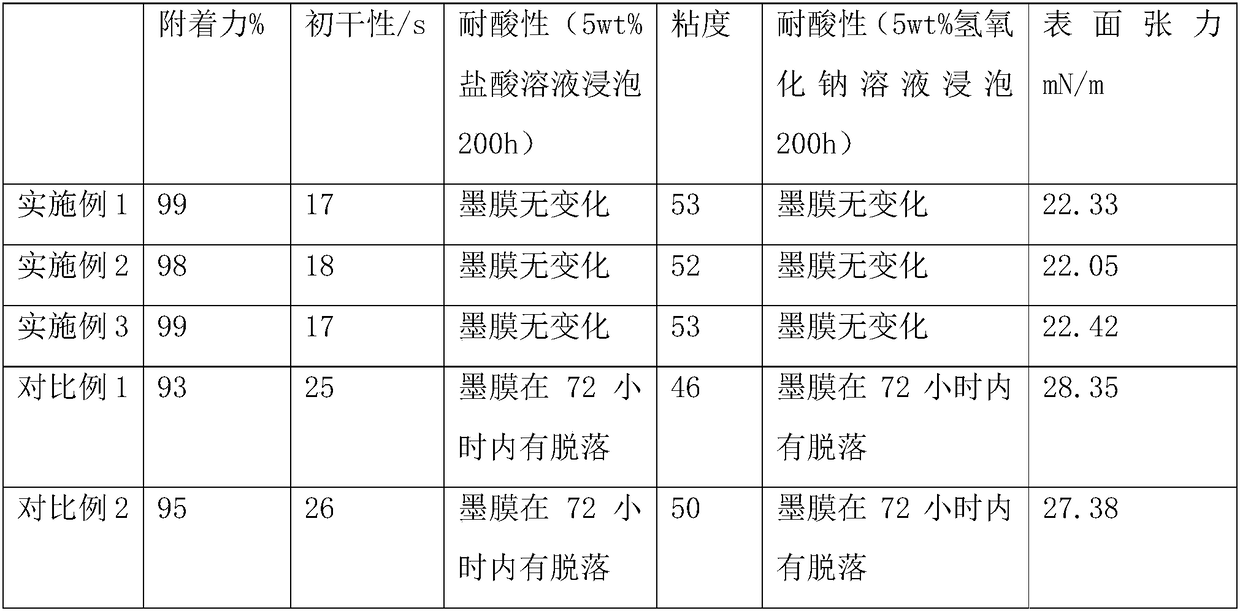

Examples

Embodiment 1

[0055] Printing ink, comprising the following components in parts by weight:

[0056] 23 parts acrylic resin

[0057] Conductive filler 25 parts

[0058] 3 parts adhesion promoter

[0059] Dispersant 0.3 parts

[0060] 0.5 parts of defoamer

[0061] Leveling agent 0.05 part

[0062] 30 parts of diluent.

[0063] The adhesion promoter is a chlorinated polyolefin, and the dispersant is a silane coupling agent;

[0064] The silane coupling agent is γ-methacryloxypropyltrimethoxysilane, and the chlorinated polyolefin is chlorinated polyethylene. The defoamer is ethylene glycol siloxane, and the leveling agent is butyl cellulose;

[0065] Described conductive filler is conductive carbon black and conductive silver powder, and the weight ratio of described conductive carbon black and conductive silver powder is 3:1, and the particle size of described conductive filler is 1 micron;

[0066] Described thinner comprises the component of following parts by weight:

[0067] 5 pa...

Embodiment 2

[0078] Printing ink, comprising the following components in parts by weight:

[0079] 38 parts acrylic resin

[0080] 32 parts of conductive filler

[0081] Adhesion Promoter 8 parts

[0082] Dispersant 1.1 parts

[0083] 1 part defoamer

[0084] Leveling agent 0.1 parts

[0085] 43 parts of diluent.

[0086] The adhesion promoter is a chlorinated polyolefin, and the dispersant is a silane coupling agent;

[0087] The silane coupling agent is γ-methacryloxypropyltrimethoxysilane, and the chlorinated polyolefin is chlorinated polyethylene.

[0088] The defoamer is ethylene glycol siloxane, and the leveling agent is butyl cellulose;

[0089] Described conductive filler is conductive carbon black and conductive silver powder, and the weight ratio of described conductive carbon black and conductive silver powder is 3:1, and the particle size of described conductive filler is 10 microns;

[0090] Described thinner comprises the component of following parts by weight:

[00...

Embodiment 3

[0102] The printing ink is characterized in that: it comprises the following components in parts by weight:

[0103] 25 parts acrylic resin

[0104] Conductive filler 28 parts

[0105] 5 parts adhesion promoter

[0106] Dispersant 0.8 parts

[0107] 0.8 parts of defoamer

[0108] Leveling agent 0.07 parts

[0109] 38 parts of diluent.

[0110] The adhesion promoter is a chlorinated polyolefin, and the dispersant is a silane coupling agent;

[0111] The silane coupling agent is γ-methacryloxypropyltrimethoxysilane, and the chlorinated polyolefin is chlorinated polyethylene.

[0112] The defoamer is ethylene glycol siloxane, and the leveling agent is butyl cellulose;

[0113] Described conductive filler is conductive carbon black and conductive silver powder, and the weight ratio of described conductive carbon black and conductive silver powder is 3:1, and the particle size of described conductive filler is 5 microns;

[0114] Described thinner comprises the component of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com