Method for eliminating tiger skin defect of polypropylene composition and polypropylene composition prepared thereby

A technology of polypropylene composition and tiger skin pattern, which is applied in the field of polymer material polypropylene, can solve problems such as no industrialized production scheme, and achieve the effects of large degree of indeterminateness, improved stability, and reduced shear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

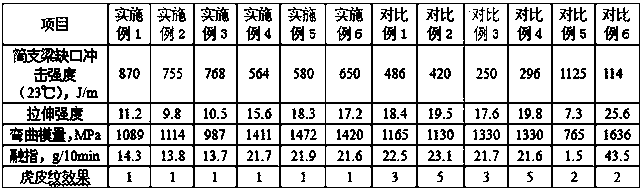

Examples

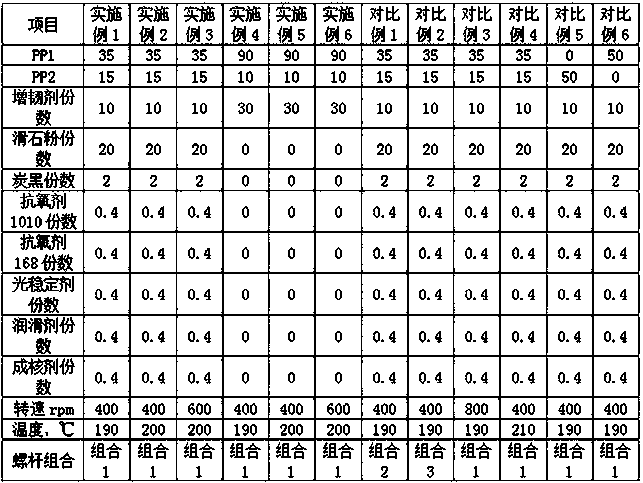

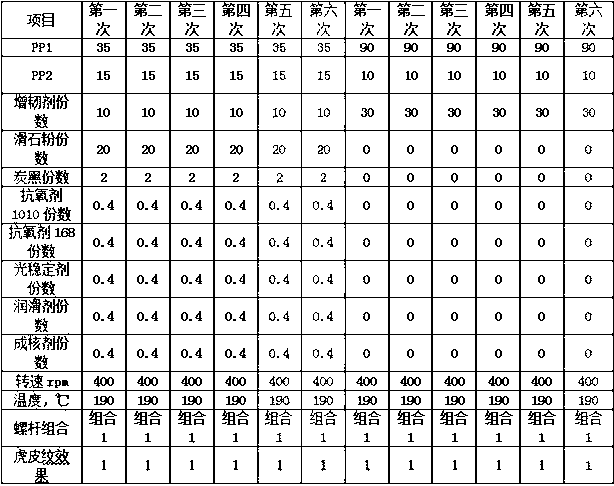

Embodiment 1

[0038] Mix the raw materials of the polypropylene composition according to the ratio in Table 1, and then add them to the twin-screw extruder, and select the screw combination 1 for melt mixing, that is, the screw combination sequence of the melting and plasticizing section of the extruder is 45 / 5 / 42 , 45 / 5 / 42, 36 / 36, 45 / 5 / 42, 45 / 5 / 42, 36 / 36, 45 / 5 / 42, 45 / 5 / 42, 45 / 5 / 42 L, in the mixing and dispersing section The screw combination sequence is 45 / 5 / 42, 45 / 5 / 42, 45 / 5 / 42, 52 / 52, 45 / 5 / 42, 45 / 5 / 42, 45 / 5 / 42, 52 / 52, 36 / 36, 45 / 5 / 42, 45 / 5 / 42, 45 / 5 / 42. The temperature of each section of the extruder is 190° C., the screw speed is 400 rpm, extruded and granulated to obtain a polypropylene composition.

Embodiment 2

[0040] Mix the raw materials of the polypropylene composition according to the ratio in Table 1, and then add them to the twin-screw extruder, and select the screw combination 1 for melt mixing, that is, the screw combination sequence of the melting and plasticizing section of the extruder is 45 / 5 / 42 , 45 / 5 / 42, 36 / 36, 45 / 5 / 42, 45 / 5 / 42, 36 / 36, 45 / 5 / 42, 45 / 5 / 42, 45 / 5 / 42 L, in the mixing and dispersing section The screw combination sequence is 45 / 5 / 42, 45 / 5 / 42, 45 / 5 / 42, 52 / 52, 45 / 5 / 42, 45 / 5 / 42, 45 / 5 / 42, 52 / 52, 36 / 36, 45 / 5 / 42, 45 / 5 / 42, 45 / 5 / 42. The temperature of each section of the extruder is 200° C., the screw speed is 400 rpm, extruded and granulated to obtain a polypropylene composition.

Embodiment 3

[0042] Mix the raw materials of the polypropylene composition according to the ratio in Table 1, and then add them to the twin-screw extruder, and select the screw combination 1 for melt mixing, that is, the screw combination sequence of the melting and plasticizing section of the extruder is 45 / 5 / 42 , 45 / 5 / 42, 36 / 36, 45 / 5 / 42, 45 / 5 / 42, 36 / 36, 45 / 5 / 42, 45 / 5 / 42, 45 / 5 / 42 L, in the mixing and dispersing section The screw combination sequence is 45 / 5 / 42, 45 / 5 / 42, 45 / 5 / 42, 52 / 52, 45 / 5 / 42, 45 / 5 / 42, 45 / 5 / 42, 52 / 52, 36 / 36, 45 / 5 / 42, 45 / 5 / 42, 45 / 5 / 42. The temperature of each section of the extruder is 200° C., the screw speed is 600 rpm, extruded and granulated to obtain a polypropylene composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com