Sulphoaluminate cement foamed concrete used in low-temperature environment and preparation method thereof

A technology of sulphoaluminate cement and foam concrete, which is applied in applications, household utensils, ceramic products, etc., and can solve the problems of sulphoaluminate cement not being steam-cured, slow sulphoaluminate cement hydration, and low strength of foam concrete, etc. problems, to achieve the effect of unaffected concrete strength, fast hardening, and early strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

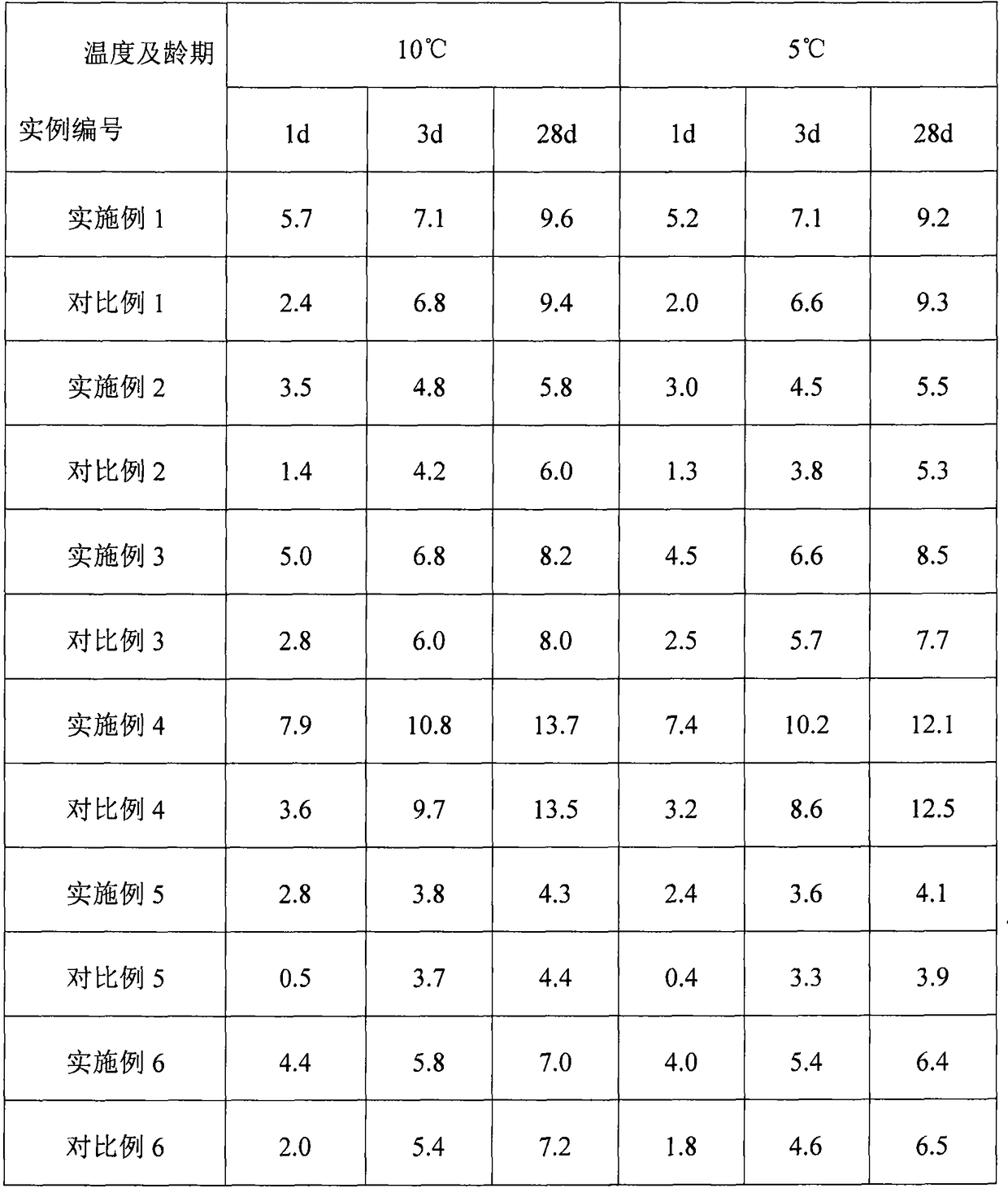

Examples

preparation example Construction

[0035] In addition, the present invention also provides a kind of preparation method of sulphoaluminate cement foam concrete, and this preparation method comprises the following steps:

[0036] 1) Weigh the sulfoaluminate cement, fly ash, concrete water, water reducer, fiber, light aggregate, and nanomaterials according to the above proportions, and then put them into the concrete mixer and mix them evenly. The mixing time is 2-4 minutes , to obtain sulphoaluminate cement slurry;

[0037]2) Weigh the foaming agent water and foaming agent according to the proportion; pour the weighed foaming agent into the foaming agent water and stir evenly for 0.5-1.5 min to obtain a foaming agent solution;

[0038] 3) Blow the foaming agent solution in step 2) into concrete foam through the foaming agent, add the concrete foam into the sulphoaluminate cement slurry obtained in step 1) according to the proportion, and continue stirring for 0.5-1.5min , to get sulphoaluminate cement foam conc...

Embodiment 1

[0040] This embodiment also provides a preparation method of sulphoaluminate cement foam concrete, the preparation method comprising the following steps:

[0041] 1) Weigh 100 parts of sulphoaluminate cement, 30 parts of concrete water, 1 part of water reducer, 0.2 part of fiber, 50 parts of light aggregate, and 1 part of nanomaterials according to the above ratio, then put them into the concrete mixer and mix them Uniform, stirring time is 3min, get sulphoaluminate cement slurry;

[0042] 2) Weigh foaming agent water and foaming agent according to the proportioning ratio of foaming agent and foaming agent water of 1:45 by weight; pour the foaming agent after weighing into foaming agent water and stir evenly, Stirring time is 1min to obtain foaming agent solution;

[0043] 3) The blowing agent solution in step 2) is blown into concrete foam through the blowing agent, and the concrete foam is added to step 1) according to the volume ratio of sulfoaluminate cement slurry and co...

Embodiment 2

[0047] This embodiment also provides a preparation method of sulphoaluminate cement foam concrete, the preparation method comprising the following steps:

[0048] 1) After weighing 75 parts of sulfoaluminate cement, 25 parts of fly ash, 25 parts of concrete water, 1.5 parts of water reducing agent, 0.3 parts of fiber, 80 parts of light aggregate and 0.2 parts of nanomaterials according to the above ratio Put it into a concrete mixer and stir evenly for 4 minutes to obtain a sulphoaluminate cement slurry;

[0049] 2) Weigh foaming agent water and foaming agent according to the proportioning ratio of foaming agent and foaming agent water in a weight ratio of 1:60; pour the weighed foaming agent into foaming agent water and stir evenly, Stirring time is 0.5min to obtain foaming agent solution;

[0050] 3) The blowing agent solution in step 2) is blown into concrete foam through the blowing agent, and the concrete foam is added to step 1) according to the volume ratio of sulfoalu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com