Remolding-realizable carbon fiber sheet material with weaving texture on whole surface and preparation method thereof

A carbon fiber board and carbon fiber board technology, which is applied in the field of composite material manufacturing, can solve the problems of destroying the appearance integrity and lack of full-surface weaving texture, and achieves the effects of fast processing speed, low production cost, good strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and embodiment example, the present invention will be further described:

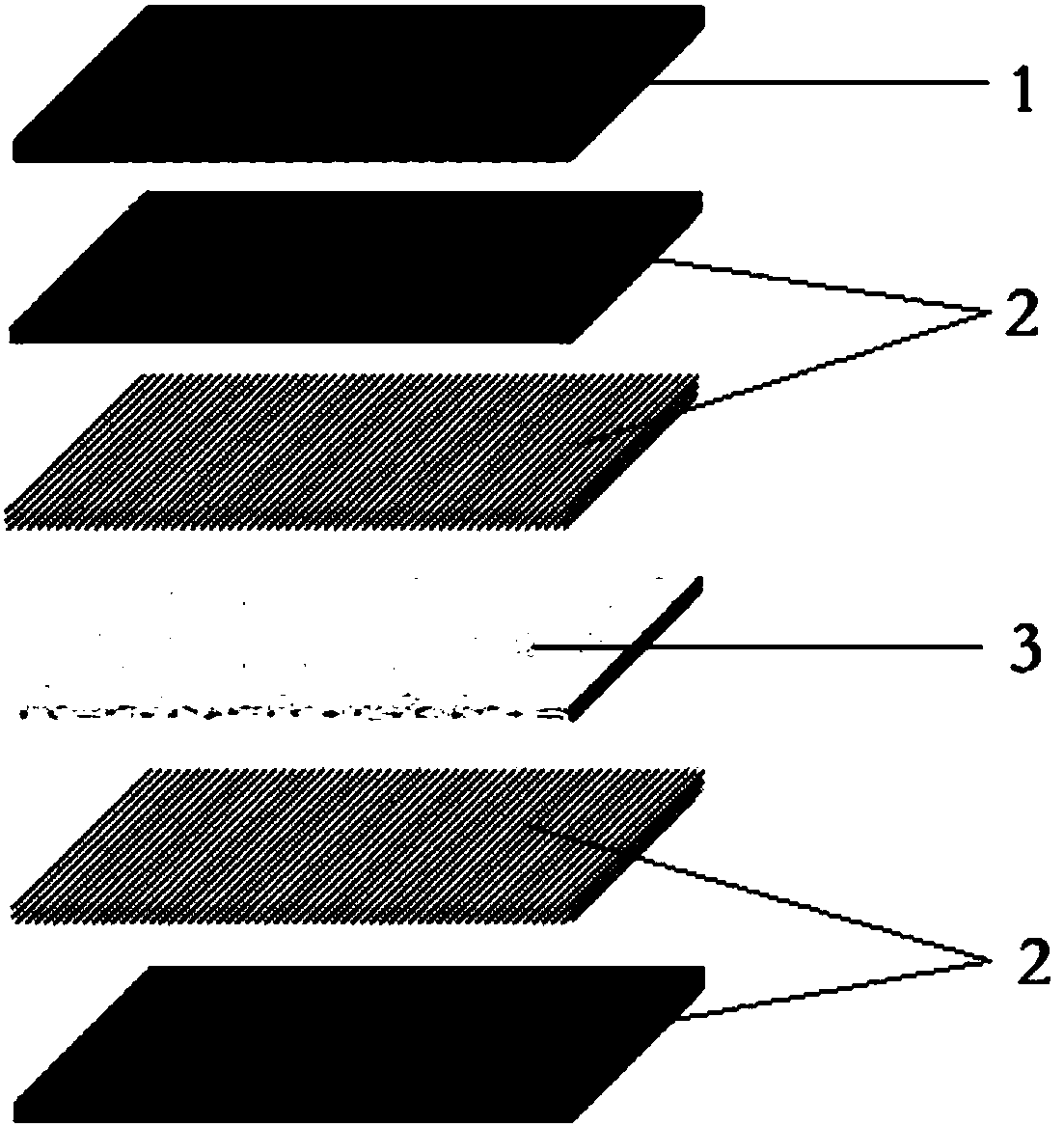

[0040] Such as figure 1 , 6 A remodelable carbon fiber sheet with a woven texture on the entire surface is shown, including a carbon fiber sheet body, the carbon fiber sheet body includes a multi-layer thermosetting carbon fiber prepreg layer 2, a glass bead-filled interlayer 3, and a glass bead-filled interlayer 2 Arranged in the middle of the multi-layer thermosetting carbon fiber prepreg layer 3, the carbon fiber plate also includes a thermoplastic carbon fiber woven cloth prepreg layer 1 arranged on the uppermost layer of the carbon fiber plate main body. Among them: the thermosetting carbon fiber prepreg layer 2 is a thermosetting unidirectional carbon fiber prepreg layer, the number of layers is an even number, and the number of layers of the thermosetting carbon fiber prepreg layer 2 located above and below the glass bead-filled interlayer 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com