Antibacterial burn-out printed fabric

A technology of burnt-out printing and fabrics, applied in the field of antibacterial burnt-out printed fabrics, can solve the problem of single function of antibacterial fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

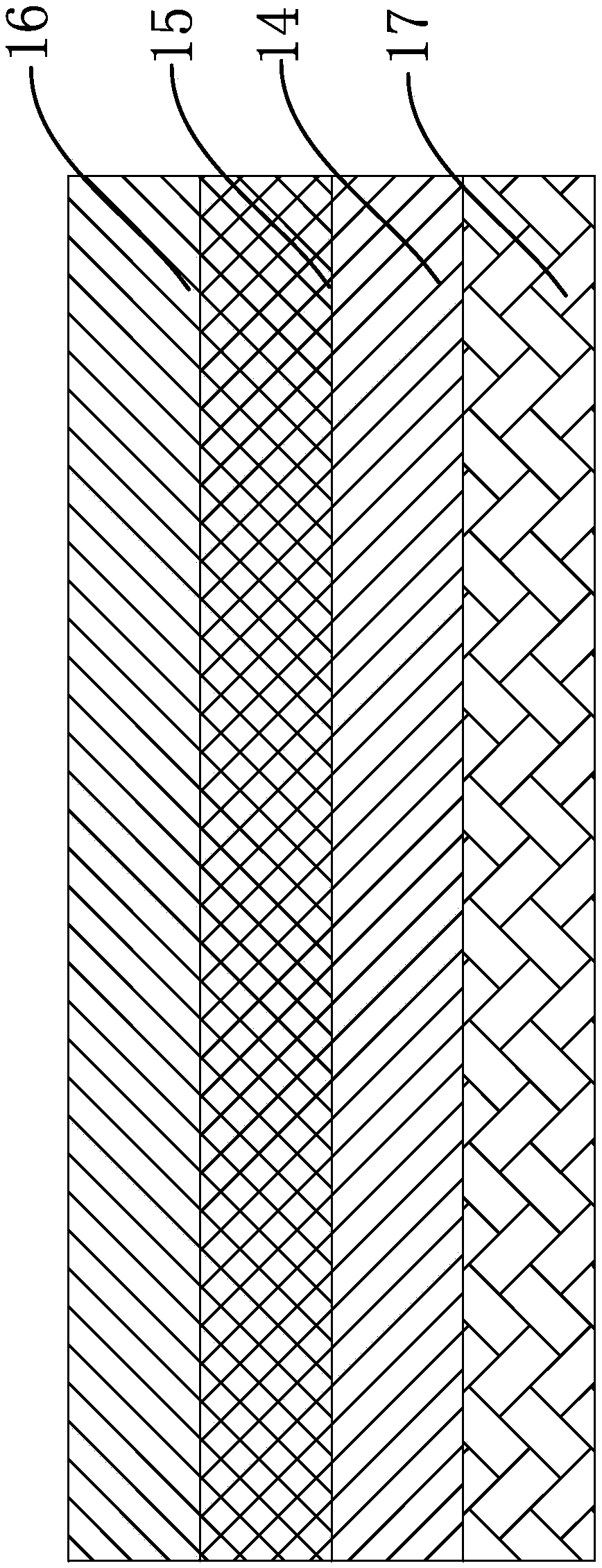

[0020] Such as figure 1 As shown, a kind of antibacterial type burnt-out printing fabric comprises base cloth layer 14, is characterized in that, base cloth layer 14 one side is provided with anti-ultraviolet layer 15 and antibacterial layer 16 successively, and base cloth layer 14 other side is provided with flame retardant layer 17; the antibacterial layer 16 is woven by nano-silver ion fibers; the nano-silver ion fibers are immersed in the antibacterial liquid for 50-60 minutes, and the pH value of the anti-bacterial liquid is 5-6; the anti-ultraviolet layer 15 is silver glue coating, anti-ultraviolet The layer 15 has a thickness of 1-2 mm; the flame-retardant layer 17 is woven from flame-retardant nylon yarn.

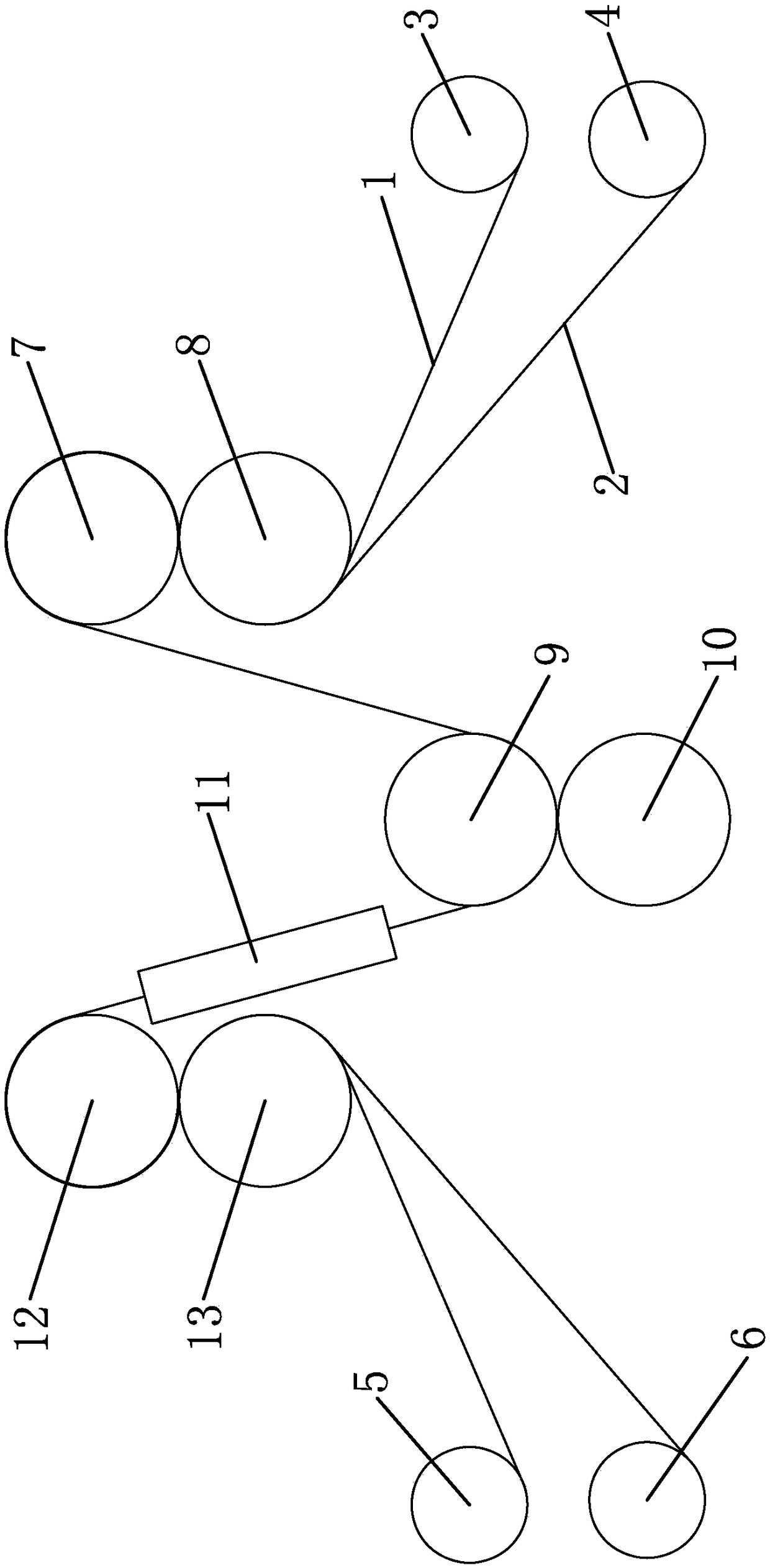

[0021]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com