Special assemblage machine for grid assembly of heat radiator

A radiator and assembly technology, which is applied in the field of radiator grille assembly assembly machine, can solve problems such as instability, inability to assemble in place, and bruises, etc., to reduce tooling costs, reduce fracturing phenomena, and improve production efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

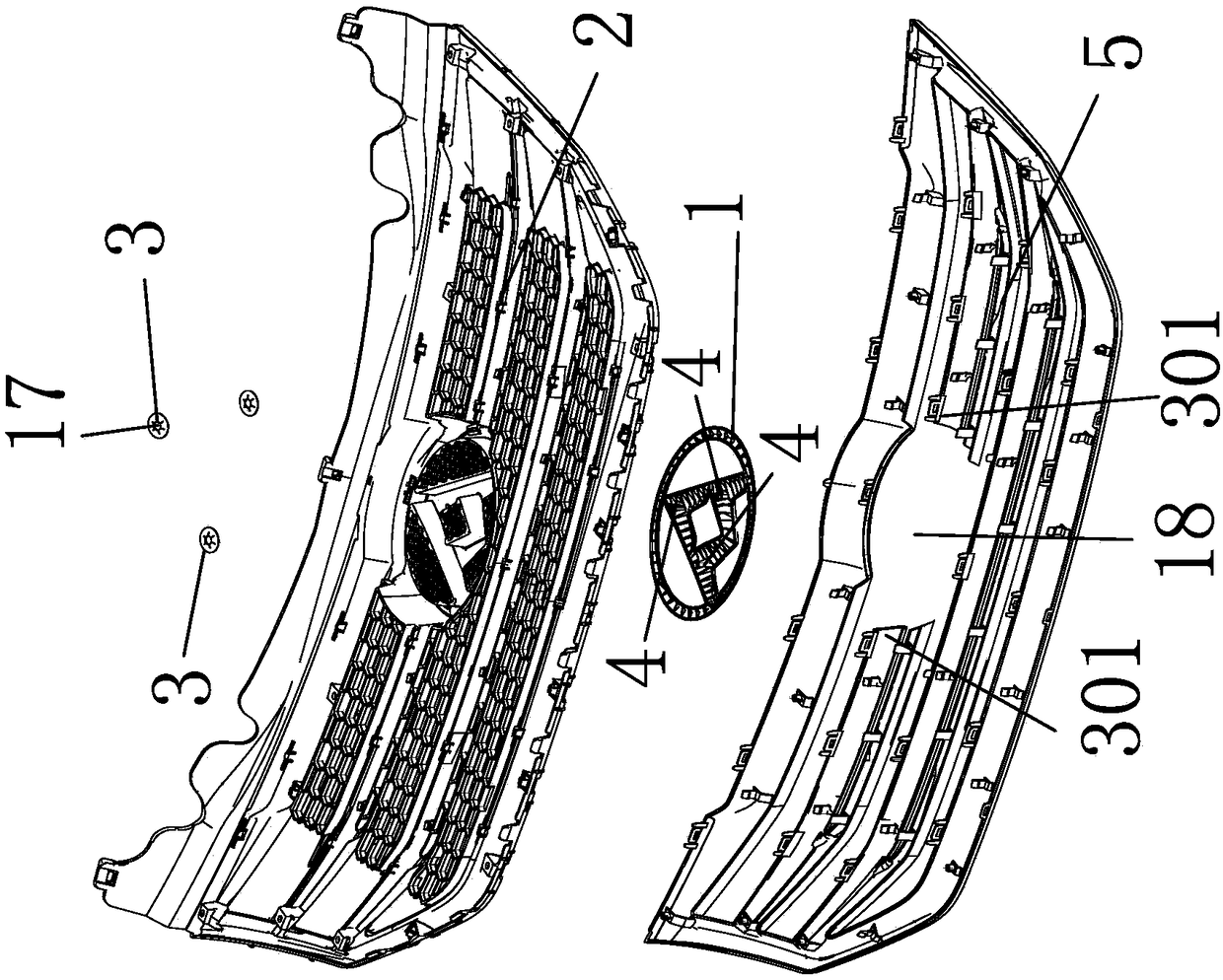

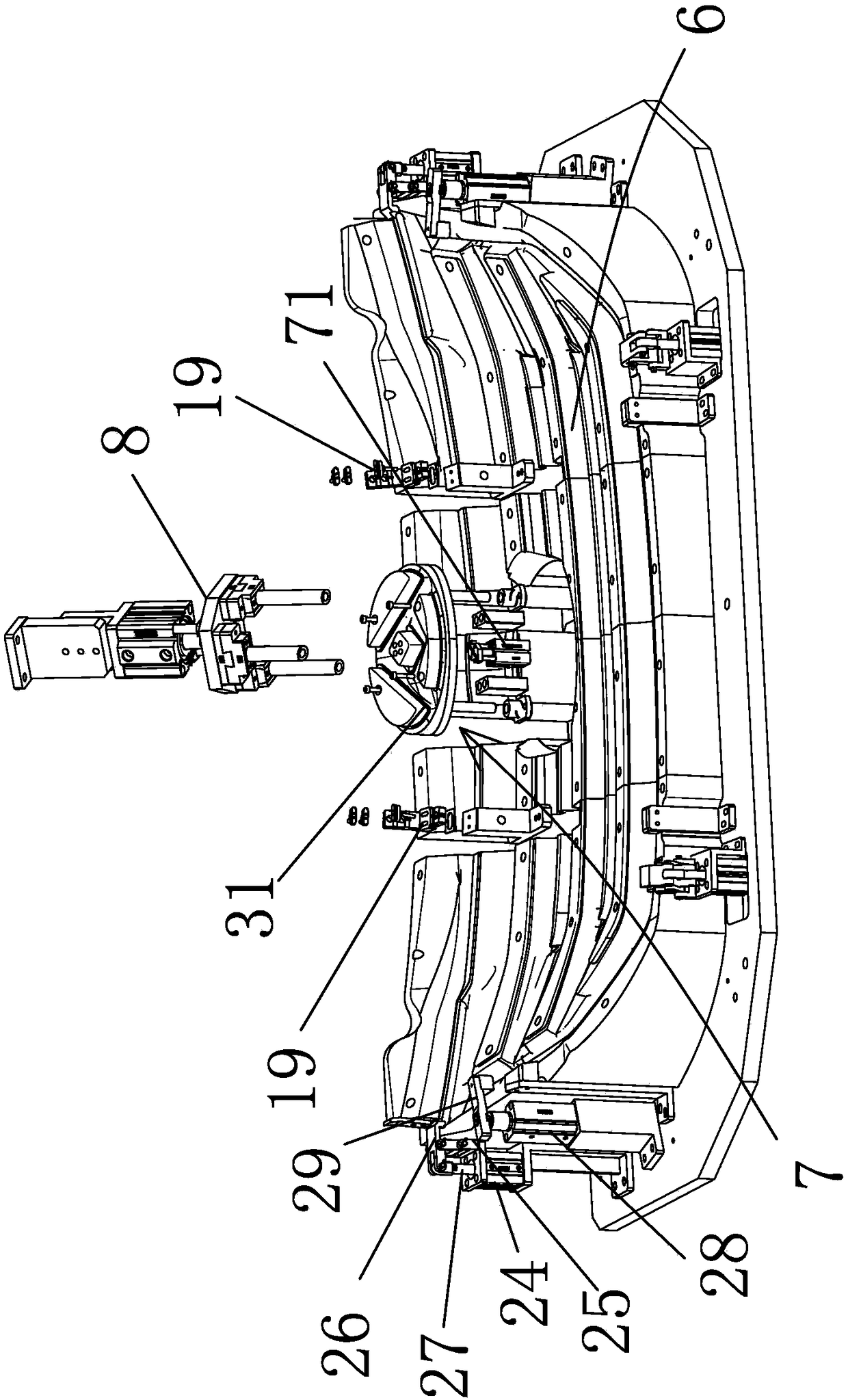

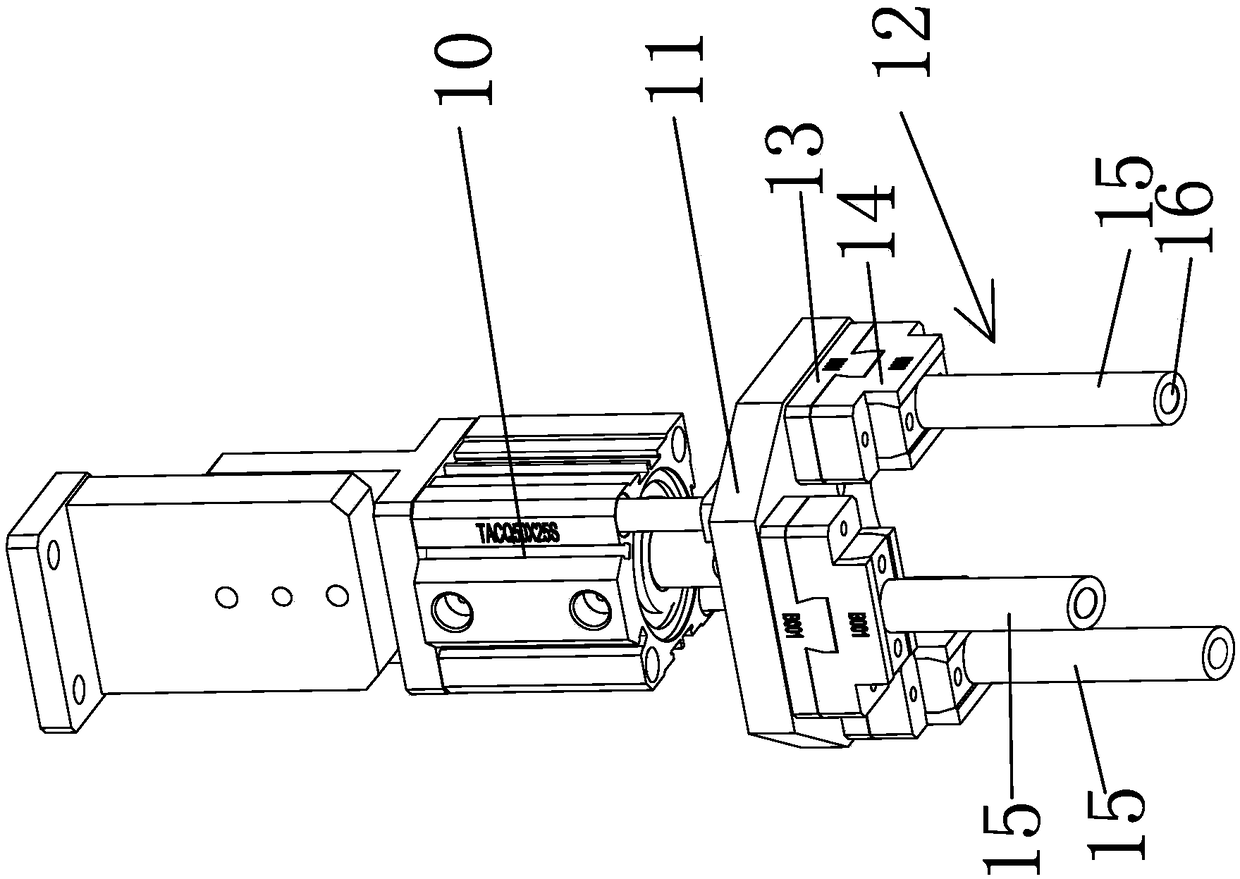

[0036] In the figure, the sign part 1; the body part 2; the spring part 3; the sleeve rod 4; the main frame 5; the main assembly stand 6; the movable support assembly 7; ; guide shaft 74; circlip pressing assembly 8; main support connection block 9; pressure rod cylinder 10; pressure rod connecting plate 11; Pressing cylinder mouth 16; snap-in cone angle 17; signage installation space 18; adsorption assembly 19; vacuum support block 20; adsorption fixing block 21; air block plug joint 22; adsorption head 23; ; Main pressing block 26; Output rod 27; Rotating cylinder 28; Rotating pressing block 29; Outer frame 30; Disconnection 301; 34; the first pressure cylinder 35; the first pressure foot 36; the pressure plane foot 37;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com