Device and method for measuring laser beam quality factor in laser-water jet composite processing

A technology of laser beam quality and composite processing, applied in interference spectroscopy, laser welding equipment, metal processing equipment, etc. The processing technology cannot be implemented quickly and easily, so as to avoid the decrease of precision and optimize the processing parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

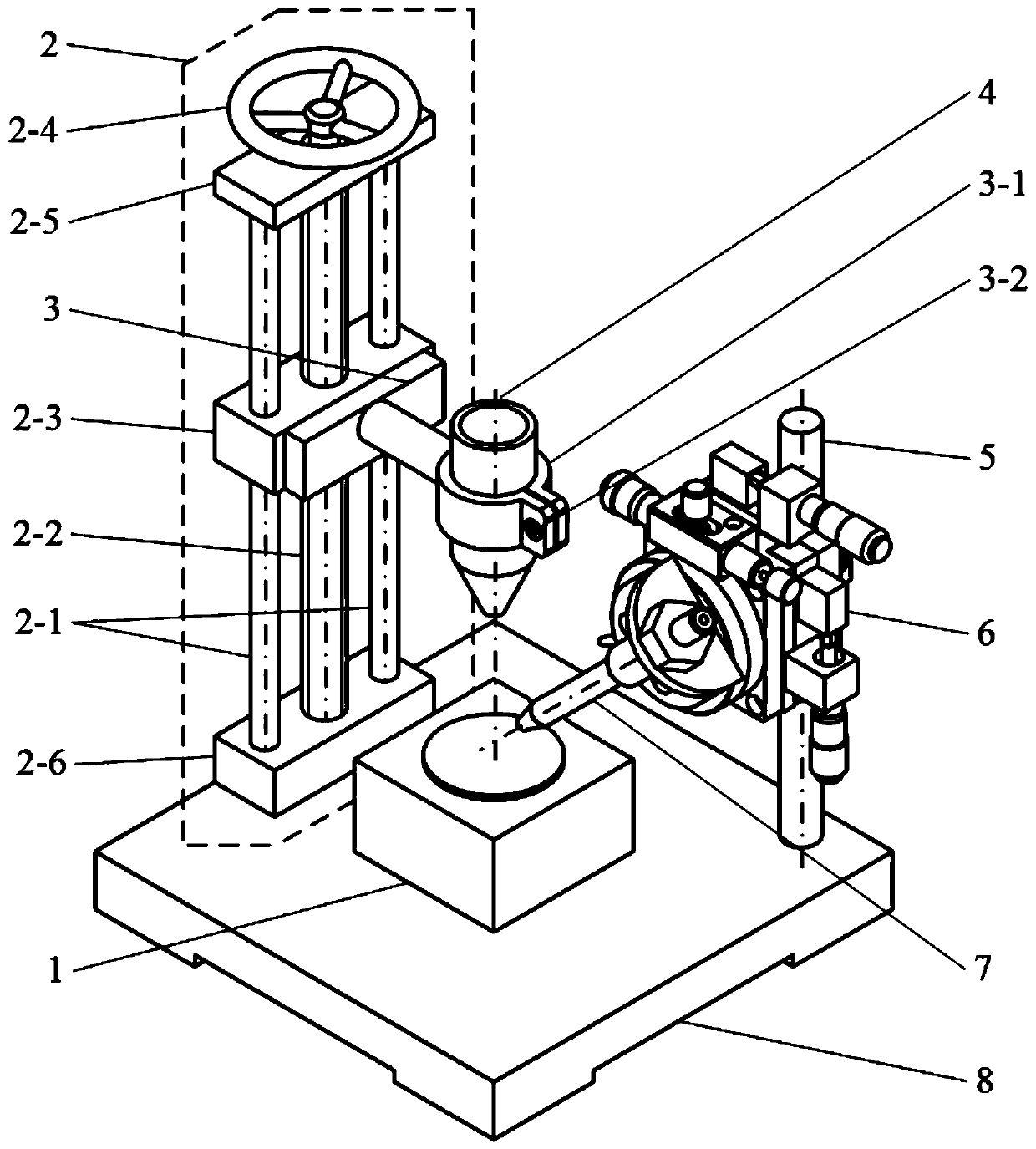

[0046] The implementation process of the laser beam quality factor measuring device in the laser-water jet composite processing is described in detail with reference to the accompanying drawings, such as figure 1 , figure 2 , image 3 , Figure 4 shown.

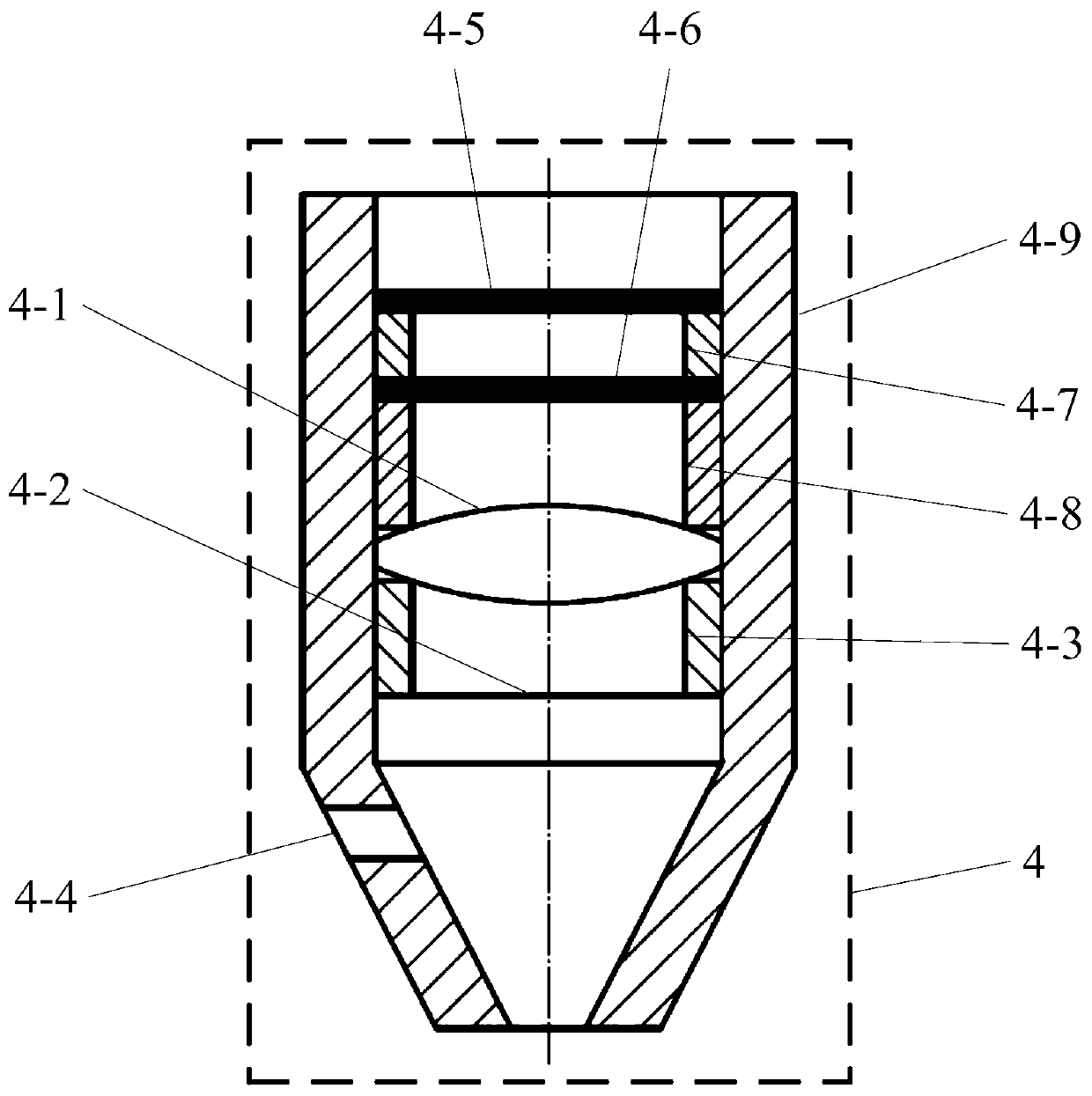

[0047] A laser beam quality factor measuring device in the laser-water jet composite processing of the present invention comprises a waterproof sealed box 1, a linear guide rail 2 driven by a lead screw, a laser focusing lens bracket 3, a laser focusing lens 4, a column 5, and a precision three Shaft motion platform 6, water jet nozzle 7, base 8, spot analyzer 9 constitute.

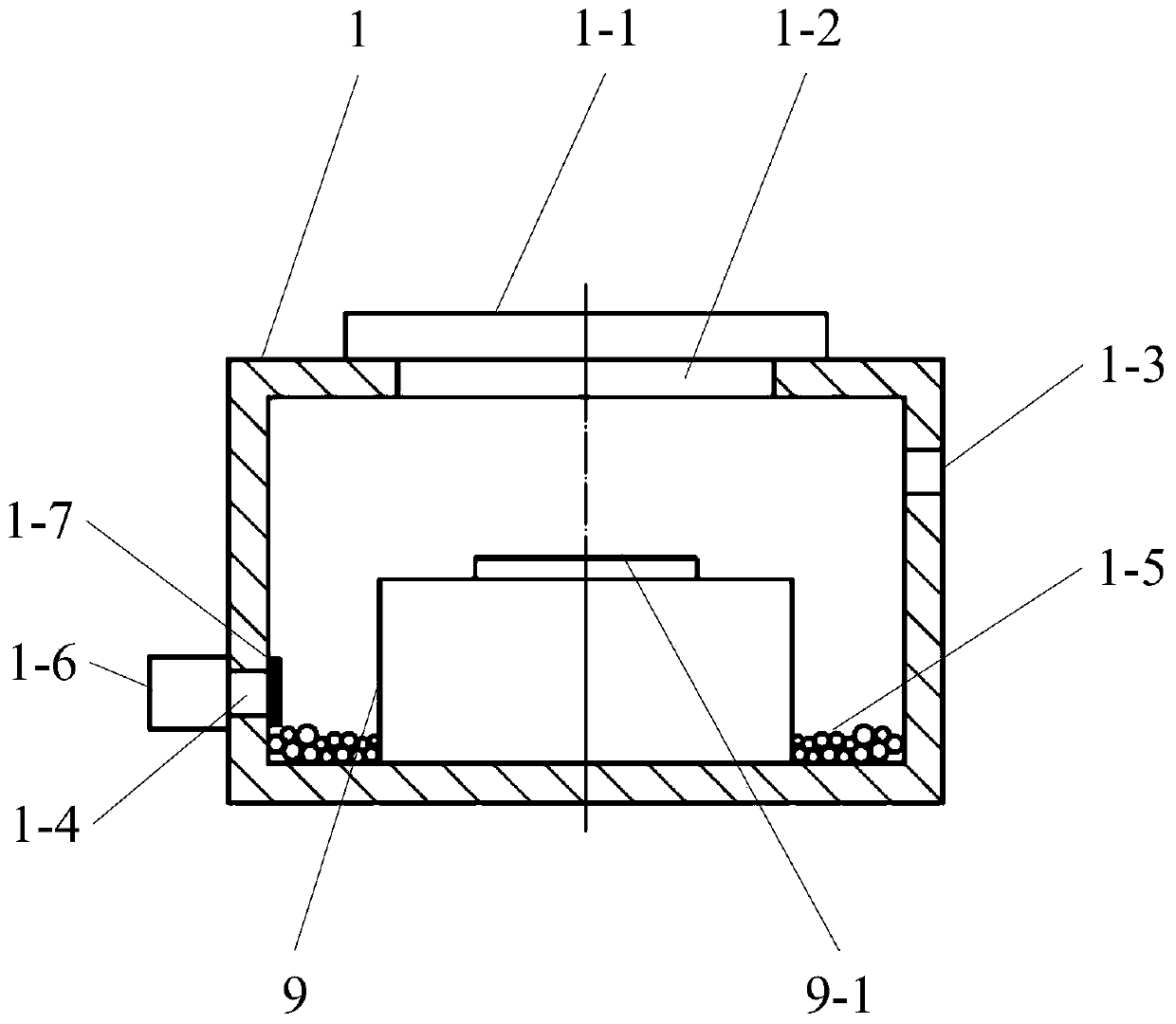

[0048] The waterproof sealed box 1 is a square box, fixedly installed on the base 8; as figure 2 As shown, a window 1-2 is set on the wall at the top of the waterproof airtight box 1, an air inlet 1-3 is set at a side wall close to the top surface, and an air inlet 1-3 is set at the lower position on the corresponding box wall. An air outlet 1-4;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com