High-oxygen storage capacity Al2O3-CeO2-ZrO2-TiO2 coating material for automobile catalysts and preparation method thereof

A coating material and oxygen storage technology, applied in catalyst protection, chemical instruments and methods, heterogeneous catalyst chemical elements, etc., can solve the problem of high impurity content, poor thermal stability and complex preparation process of cerium-zirconium-based oxygen storage materials and other problems, to achieve the effect of improving activity and thermal stability, reducing production cost and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

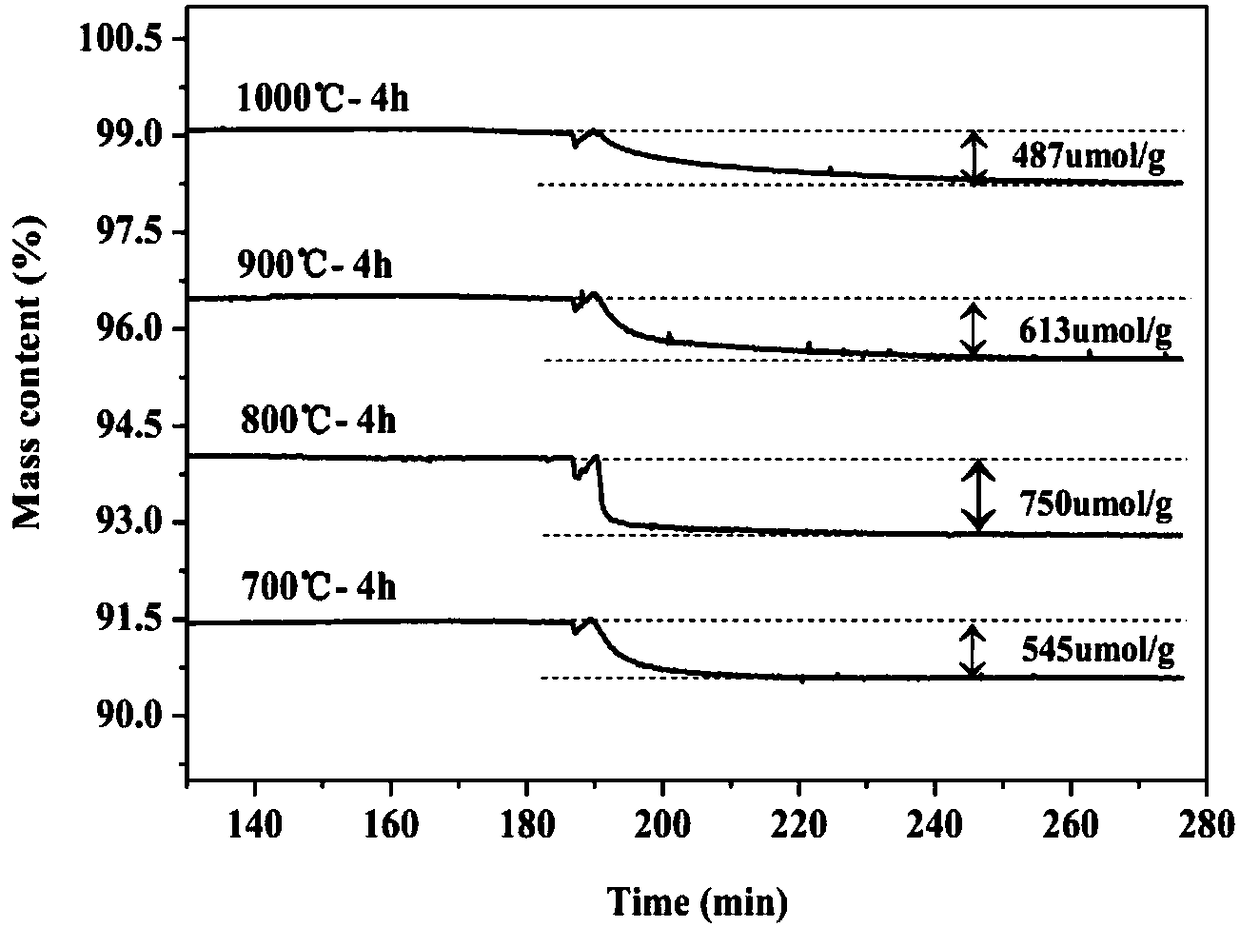

[0020] First weigh the CeO-containing 2 Dissolve 25g of cerium nitrate salt in appropriate deionized water, and add Al containing 2 o 3 60g of pseudoboehmite and 5g of nano anatase TiO 2 , add dropwise 2ml hydrogen peroxide (30wt%) after continuing to stir for 30min, and add the ZrO containing ZrO after 5 minutes 2 For 10g of zirconium acetate, keep stirring until the slurry becomes a sol. Finally, the sol was dried at 120°C and calcined at 700°C for 4 hours to obtain AlCeZrTiO with high oxygen storage capacity for automotive catalysts x coating material.

[0021] The AlCeZrTiO x The specific surface area of the coating material is 147.32m 2 / g, the oxygen storage capacity is 537μmol / g.

Embodiment 2

[0023] First weigh the CeO-containing 2 Dissolve 45g of cerium nitrate salt in appropriate deionized water, and add Al containing 2 o 3 40g of pseudoboehmite and 5g of nano anatase TiO 2 , add dropwise 8ml hydrogen peroxide (30wt%) after stirring continuously for 30min, and add ZrO after 5 minutes 2 For 10g of zirconium acetate, keep stirring until the slurry becomes a sol. Finally, the sol was dried at 200°C and calcined at 700°C for 4 hours to obtain AlCeZrTiO with high oxygen storage capacity for automotive catalysts x coating material.

[0024] The AlCeZrTiO x The specific surface area of the coating material is 135.47m 2 / g, the oxygen storage capacity is 701μmol / g.

Embodiment 3

[0026] First weigh the CeO-containing 2 Dissolve 35g of cerium nitrate salt in appropriate deionized water, and add Al containing 2 o 3 50g of pseudoboehmite and 2g of nano anatase TiO 2 , after continuous stirring for 30min, 5ml hydrogen peroxide (30wt%) was added dropwise, and after 5 minutes, ZrO-containing 2 For 13g of zirconium acetate, keep stirring until the slurry becomes a sol. Finally, the sol was dried at 120°C and calcined at 700°C for 4 hours to obtain AlCeZrTiO with high oxygen storage capacity for automotive catalysts x coating material.

[0027] The AlCeZrTiO x The specific surface area of the coating material is 167.656m 2 / g, the oxygen storage capacity is 545μmol / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com