Efficient grain drying equipment

A drying equipment and grain technology, applied in the direction of drying and preserving seeds, etc., can solve the problems of automatic turning over, poor drying effect, poor impurity removal effect, etc., to shorten the drying time and structure Simple, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

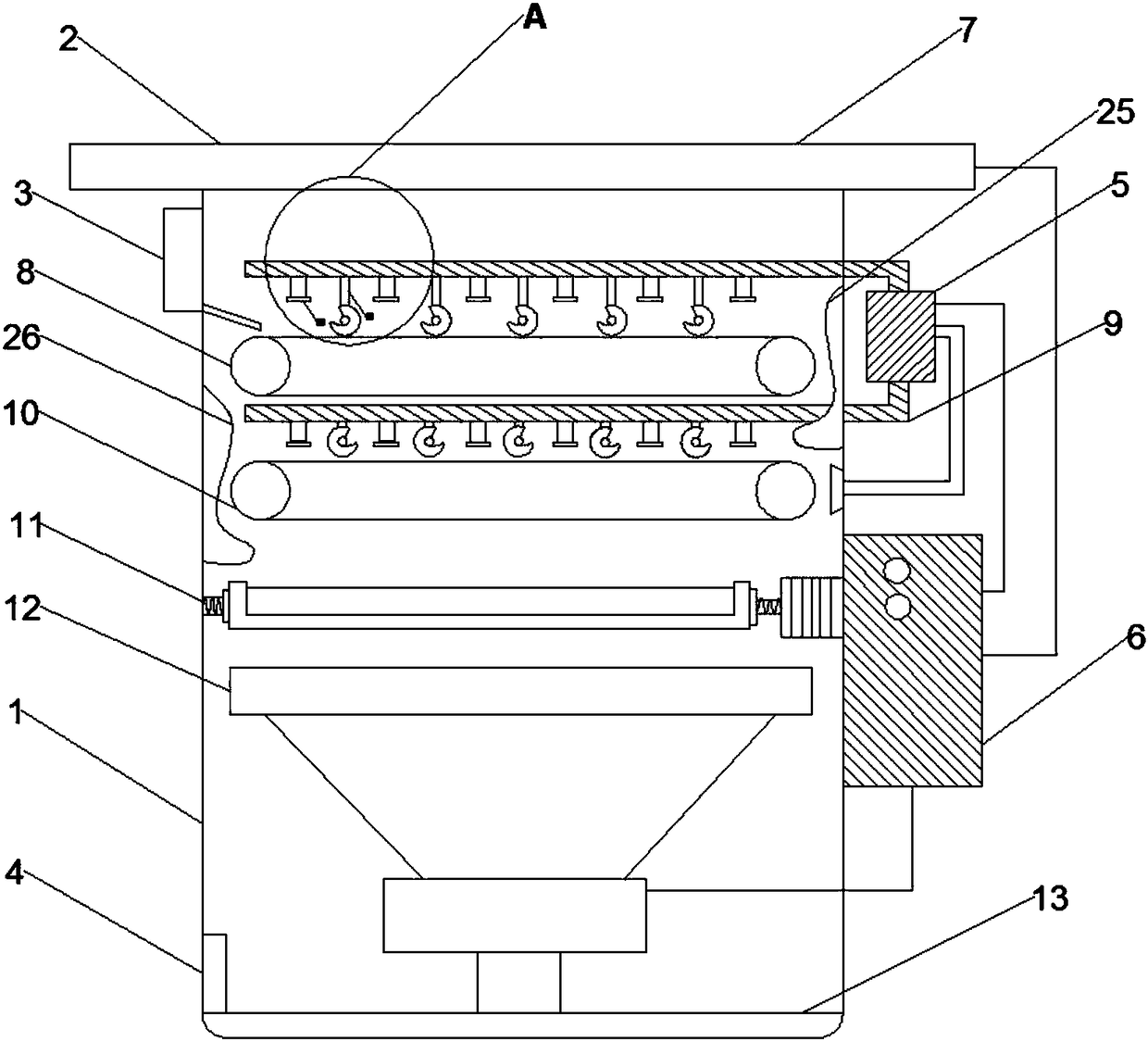

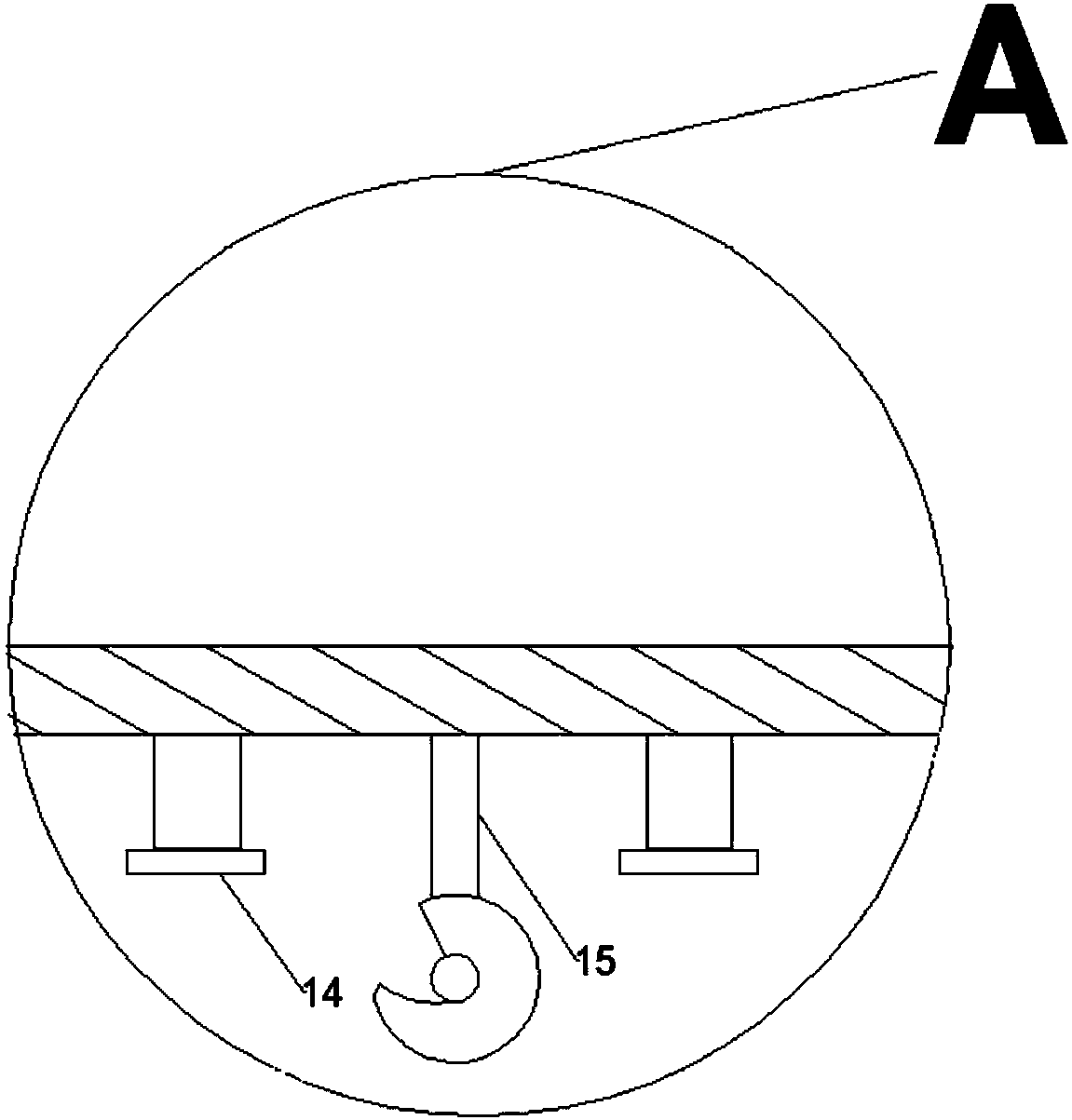

[0025] Such as Figure 1-3 As shown, a high-efficiency grain drying equipment includes an equipment main body 1 and a solar panel 2 arranged above the equipment main body 1. One side of the equipment main body 1 is provided with a material inlet 3 and a material outlet 4, and the opposite surface is provided with There is a blower 5 and a controller 6. The controller 6 is located at the lower end of the blower 5 and is electrically connected to the solar panel 2. The main body of the device 1 is provided with a first air supply pipe 7 and a first transmission device in sequence from top to bottom. 8. The second air supply pipe 9, the second conveying device 10, the vibrating device 11, the drying device 12 and the screen 13;

[0026] The first air supply pipe 7 and the second air supply pipe 9 are respectively connected with two air outlet ends of the air blower 5, and the air inlet end of the air blower 5 is positioned at the right end of the second conveying device 10, and t...

Embodiment 2

[0029] Based on Embodiment 1, the mesh radius of the screen 13 is smaller than that of the grain.

[0030] The sieve 13 in the present embodiment plays a role of screening and filtering, and the impurities whose volume is smaller than the grain are filtered and fall into the sieve 13, and the grain stays above the sieve 13.

Embodiment 3

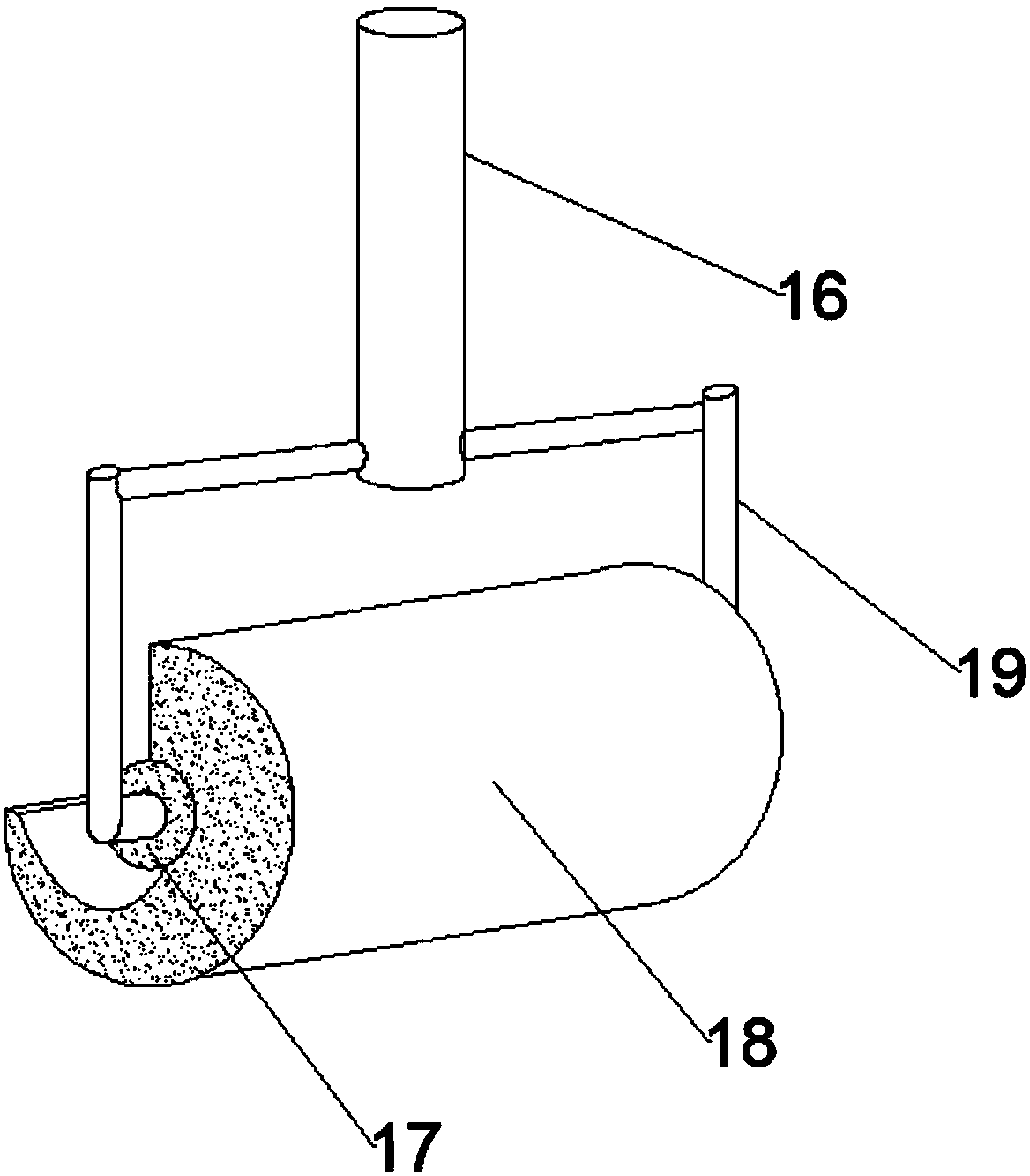

[0032] Based on Embodiment 1, the opening of the rotating drum 18 of the turning device 15 on the first air supply pipe 7 faces the direction of the feed port 3, and the rotating drum of the turning device 15 on the second air supply pipe 9 The opening of 18 is towards the blower 5 direction.

[0033] In this embodiment, the motor on the first air supply pipe 7 drives the drum to rotate clockwise, and the motor on the second air supply pipe 9 drives the drum to rotate counterclockwise, so as to ensure that the openings of the drum 18 are all facing the grain conveying direction, which can realize Roll the grain into the drum to turn the grain over.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com