Die bonder

A technology of chip bonding and bonding layer, applied in welding equipment, laser welding equipment, electrical components, etc., can solve problems such as difficulty and productivity deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, preferred embodiments of the die bonder according to the present invention will be described in detail with reference to the drawings.

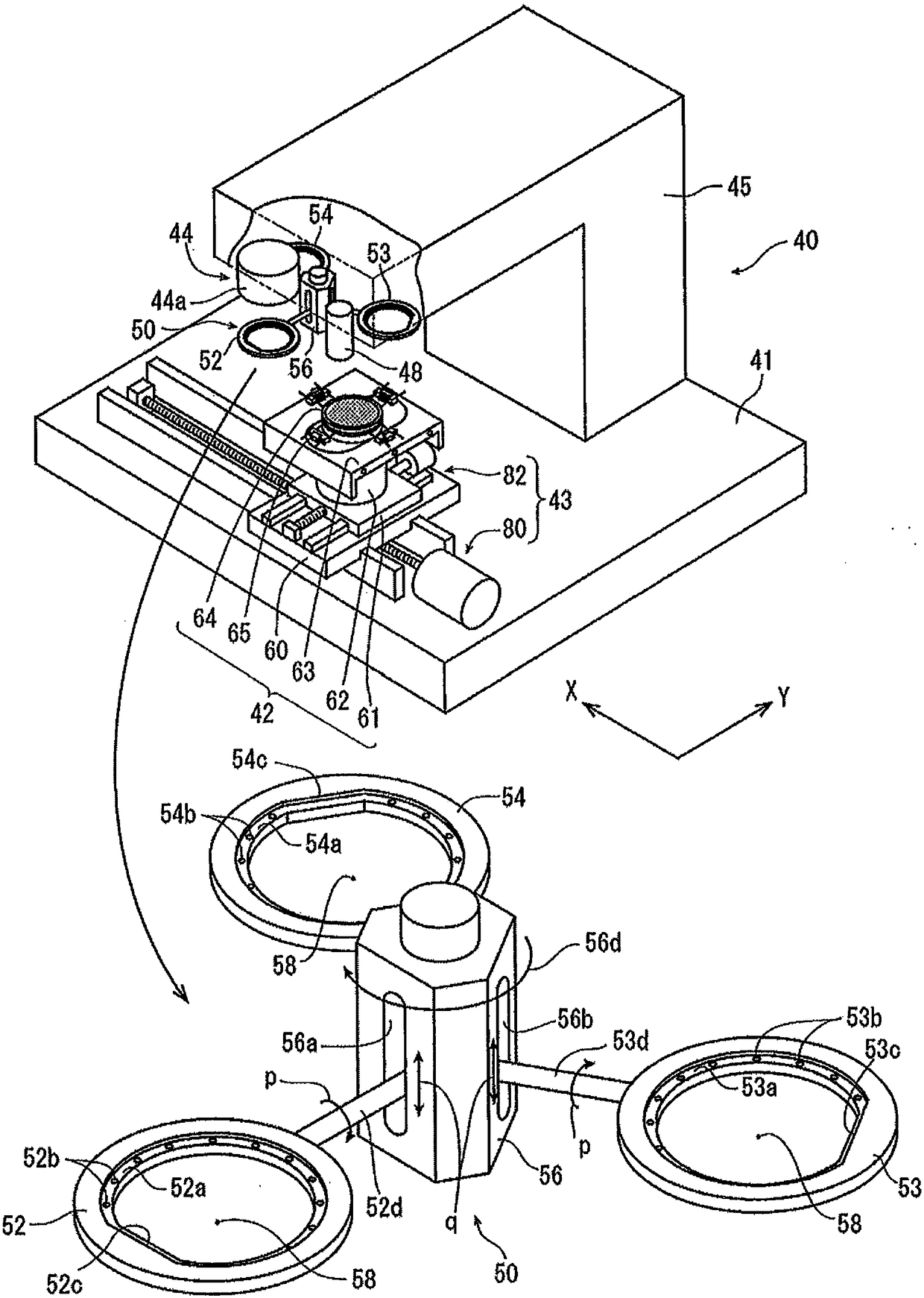

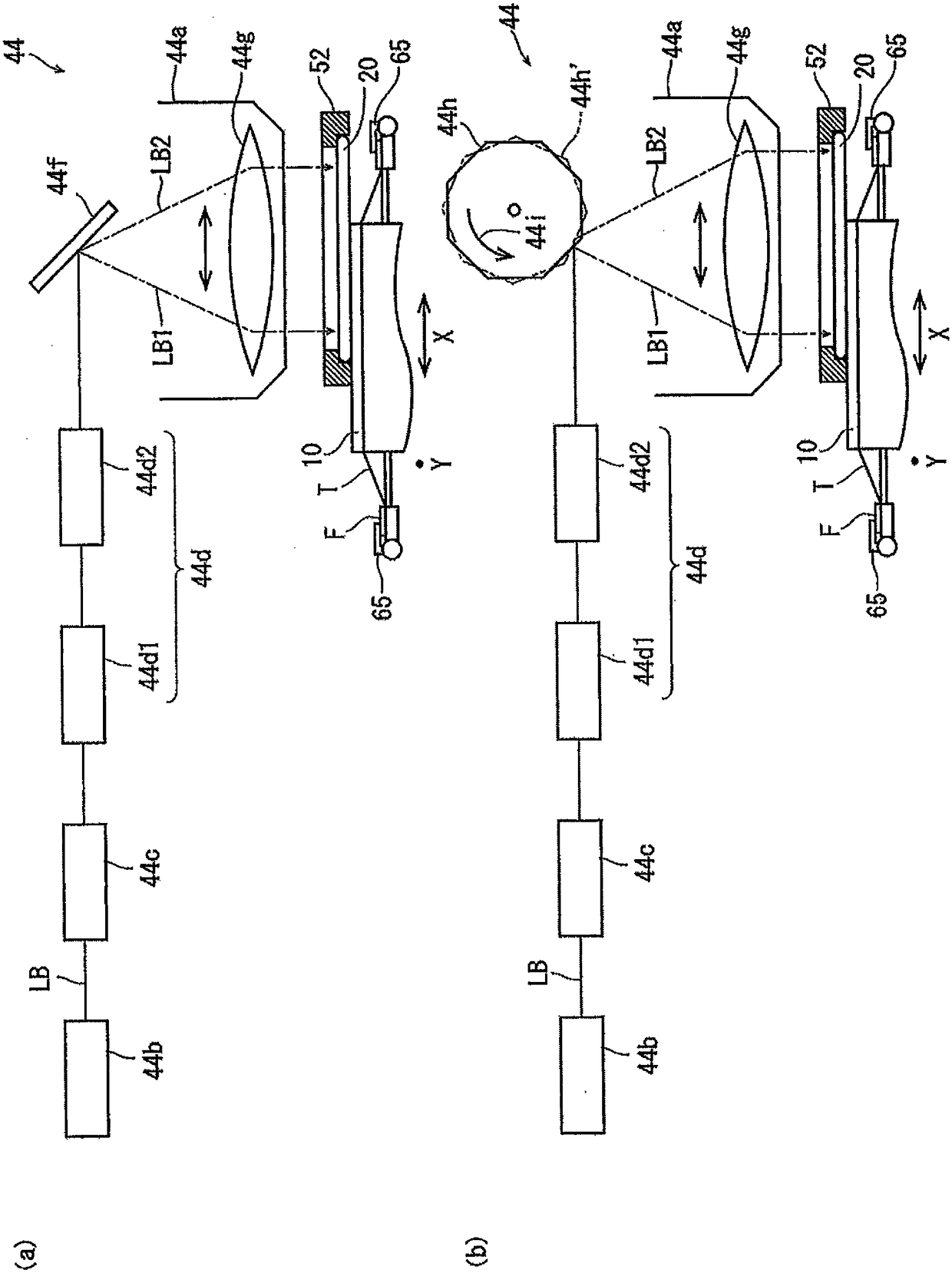

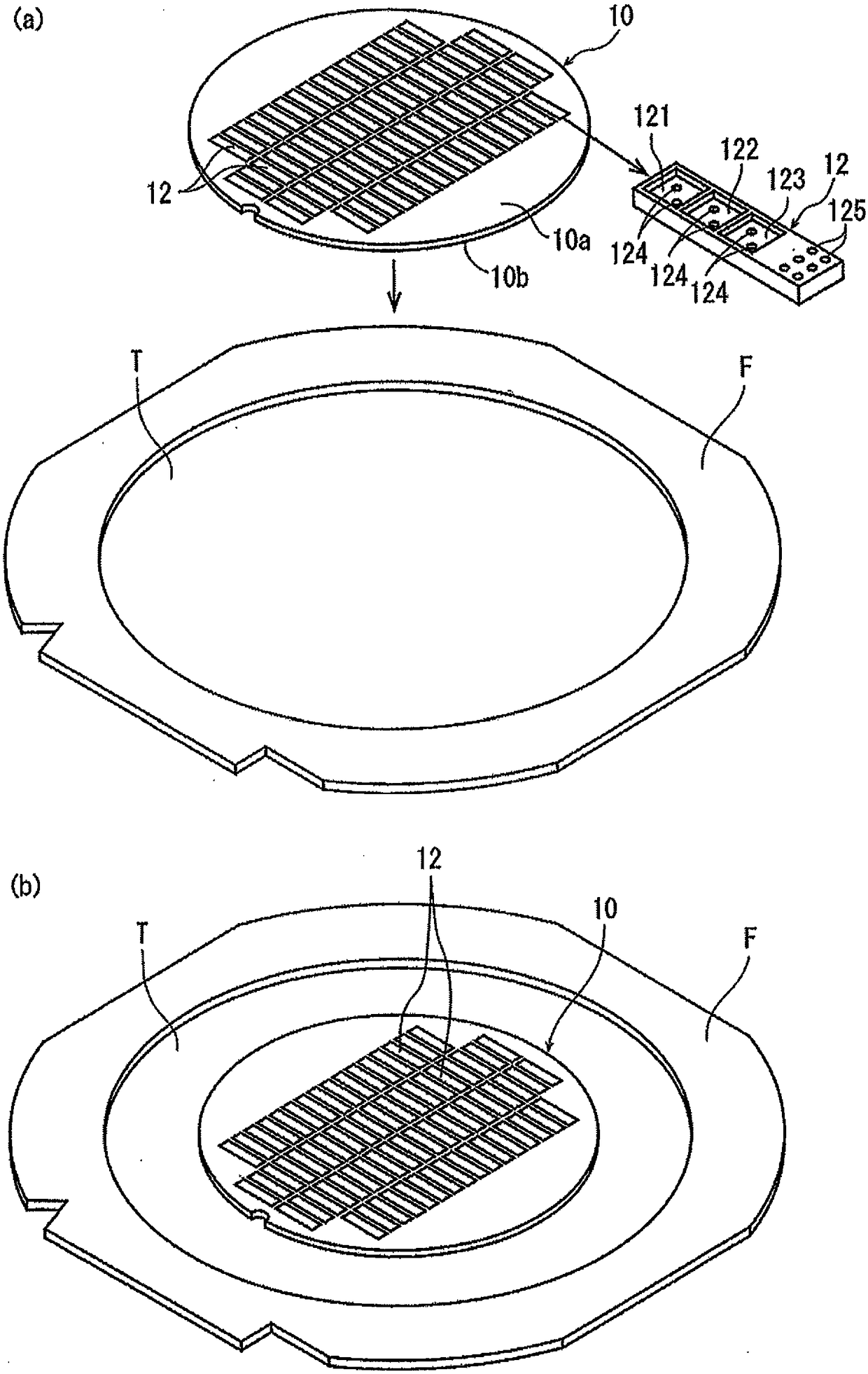

[0027] refer to figure 1 , the die bonder 40 in this embodiment will be described. The die bonding machine 40 shown in the figure has: a base 41; a substrate holding unit 42, which holds a substrate bonded with a device; a moving unit 43, which moves the substrate holding unit 42; and a laser light irradiation unit 44, which irradiates laser light; casing 45, which extends upward from the upper surface of base 41, and then extends substantially horizontally, and houses the laser light irradiation unit 44; and a control unit, which is composed of a computer described later. 40 is configured to control each unit by the control unit. In addition, on the lower surface of the front end portion of the housing 45 extending horizontally, there are provided: a condenser 44a constituting the laser beam irradiation unit 44, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com