High temperature resistant photoelectric composite optical fiber for oil well and production method thereof

A technology of photoelectric composite and production method, applied in the direction of insulated cables, communication cables, cables, etc., can solve the problems of low working temperature and low pressure, and achieve the effects of good high and low temperature resistance, small cable diameter, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

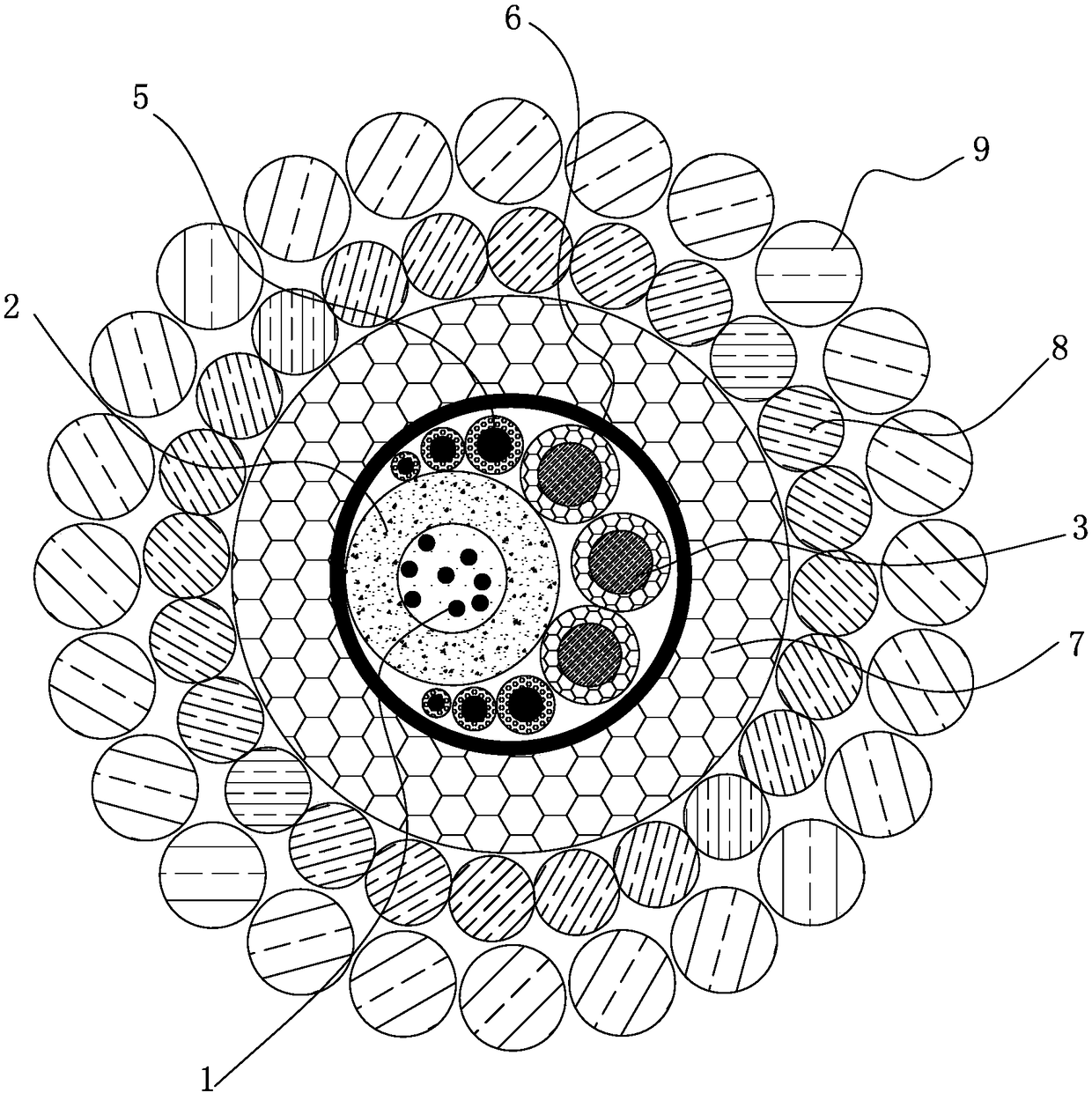

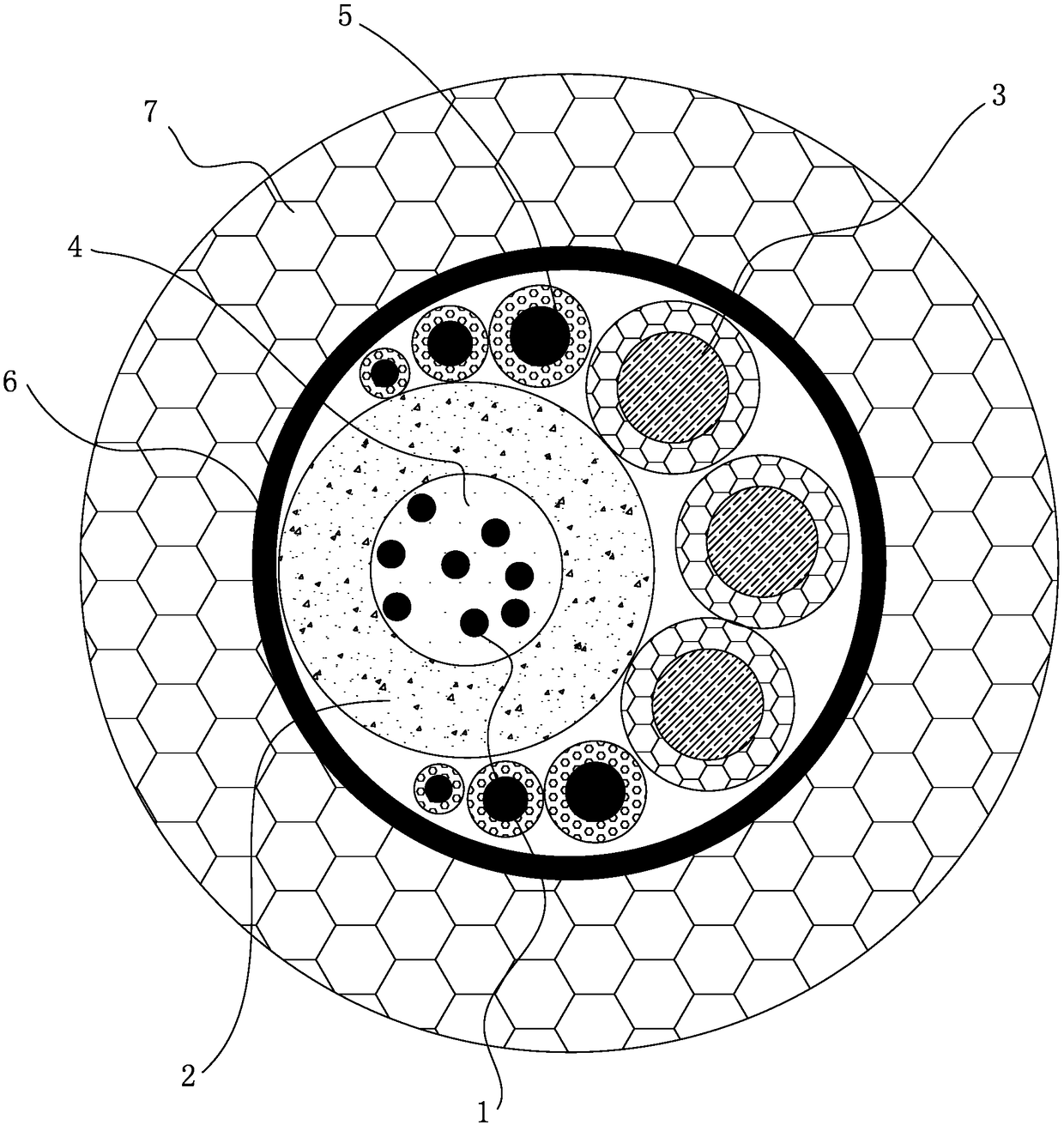

[0023] In order to clearly illustrate the technical features of the present solution, the present invention will be described in detail below through specific implementation methods and in conjunction with the accompanying drawings. It should be noted that components illustrated in the figures are not necessarily drawn to scale. Descriptions of well-known components and techniques are omitted herein to avoid unnecessarily limiting the present invention.

[0024] like figure 1 and figure 2 As shown, a high-temperature-resistant photoelectric composite optical cable for oil wells includes an optical fiber unit, a conductor unit, a filling unit, a covering unit and an armoring unit. The optical fiber unit is located at an eccentric position on one side of the composite optical cable, and includes an optical fiber 1 coated with a high-temperature-resistant polyimide layer and a stainless steel tube 2 for enclosing the optical fiber 1; between the stainless steel tube 2 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com