Wet spunlace composite material and manufacturing method

A technology of composite materials and manufacturing methods, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, cellulose plastic material layered products, etc., can solve the problems of high vertical and horizontal fracture strength and limited fracture strength, and achieve fiber protection. Net uniformity, convenient operation, and the effect of improving product physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

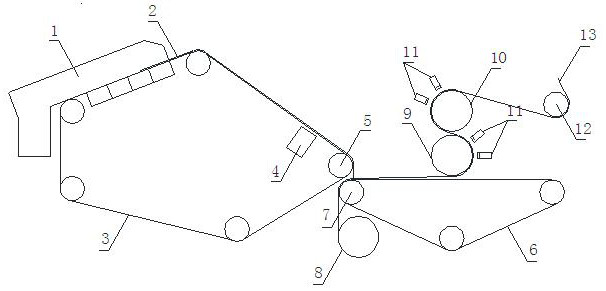

[0012] Embodiment 1: with reference to attached Figure 1-3 . A wet-process spunlace composite material is a double-layer structure, the upper layer is a wet-laid fiber net, and the lower layer is a woven cloth. The wet-laid fiber web is composed of wood pulp or cotton pulp with a weight percentage of 60-100% and ultra-short fibers with a weight percentage of 40-0% and a length of 3-20mm. The ultra-short fibers include: one or both of rayon ultra-short fibers, polyester ultra-short fibers, polylactic acid (PLA) ultra-short fibers, ES ultra-short fibers, polyvinyl alcohol ultra-short fibers, and aramid ultra-short fibers. kind of mix. When the two are mixed, the percentage by weight of one of artificial cellulose ultra-short fibers, polyester ultra-short fibers, polylactic acid (PLA) ultra-short fibers, and aramid ultra-short fibers is 20 to 39% (such as 21%, 22% , 23%, 24%, 25%, 26%, 27%, 28%, 29%, 30%, 31%, 32%, 33%, 34%, 35%, 36%, 37%, 38%, 39 %), the weight percentage o...

Embodiment 2

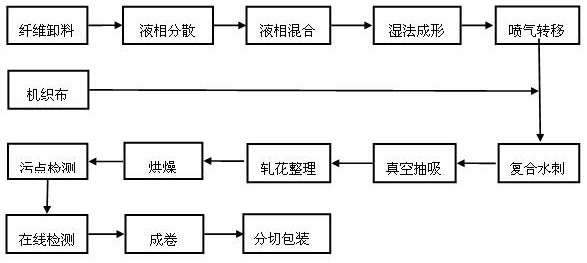

[0014] Example 2: A method for manufacturing a wet-process spunlace composite material, (1) respectively combining wood pulp or cotton pulp fibers with a weight percentage of 60-100% and ultra-short fibers with a length of 3-20mm and a weight percentage of 40-0% Add water in the unloading tank and mix it into a slurry with a concentration of 1-3%, complete the liquid phase dispersion, and then complete the liquid phase mixing in the batching tank; ultra-short fibers include: artificial cellulose ultra-short fiber, polyester ultra-short fiber, One or a mixture of polylactic acid ultra-short fibers, ES ultra-short fibers, polyvinyl alcohol ultra-short fibers, and aramid ultra-short fibers. When the two are mixed, the weight percentage of one of artificial cellulose ultra-short fiber, polyester ultra-short fiber, polylactic acid (PLA) ultra-short fiber and aramid ultra-short fiber is 20-39%, ES ultra-short fiber, polyester The weight percentage of one of the vinyl alcohol ultra-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com