Five-phase inverter of dual three-phase motor and vector control method thereof

A five-phase inverter, three-phase motor technology, applied in vector control system, motor generator control, AC motor control and other directions, can solve the problem of high hardware cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail below in conjunction with accompanying drawing:

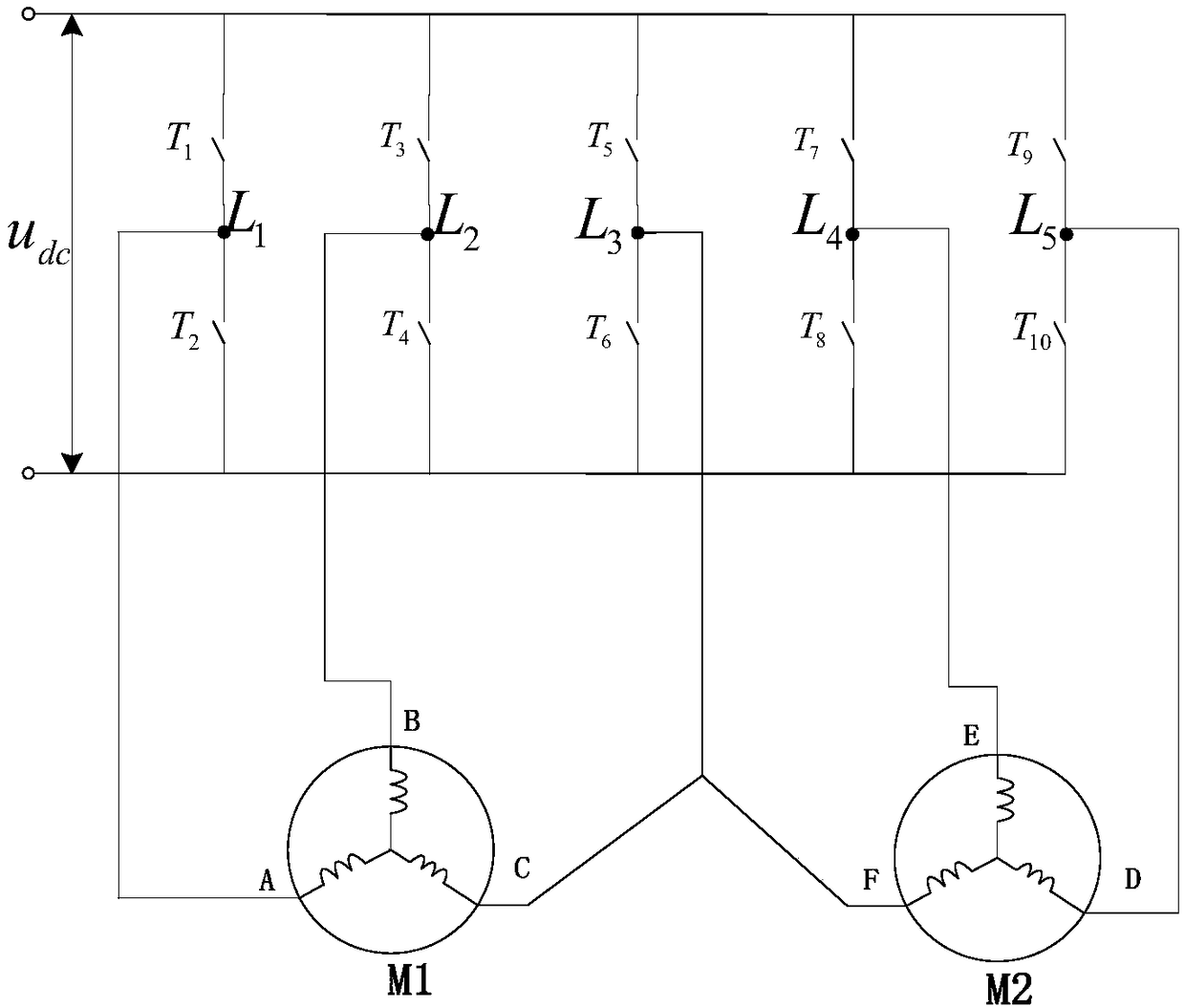

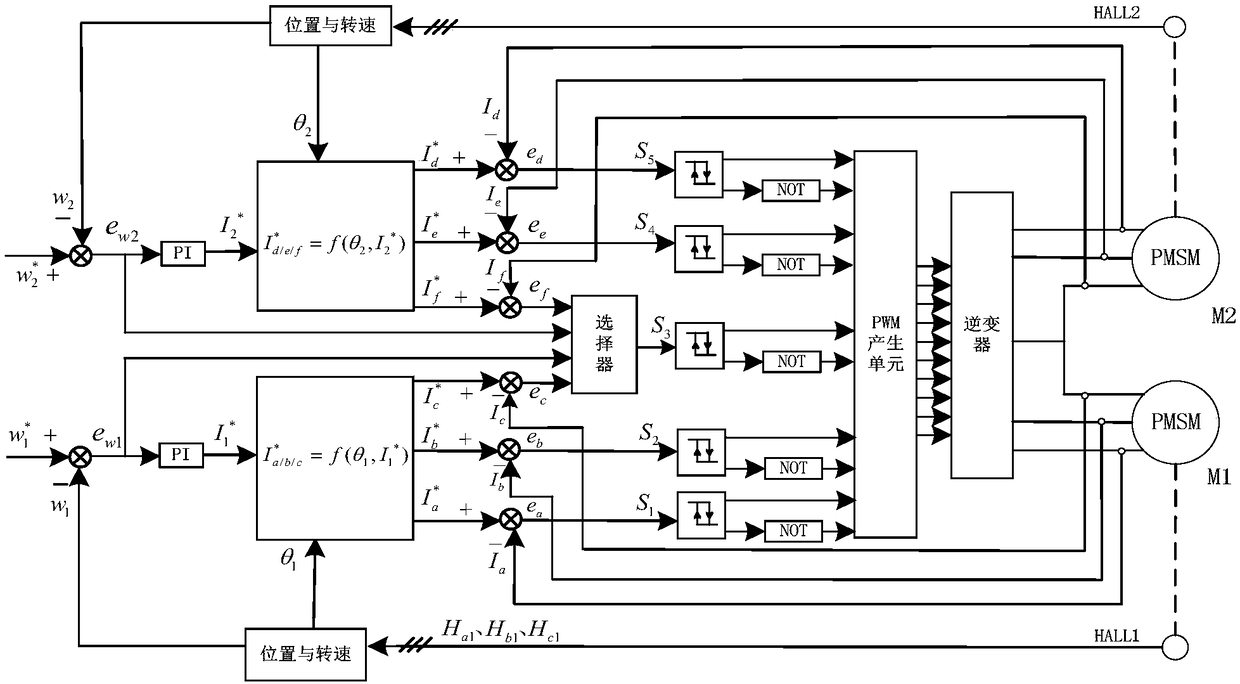

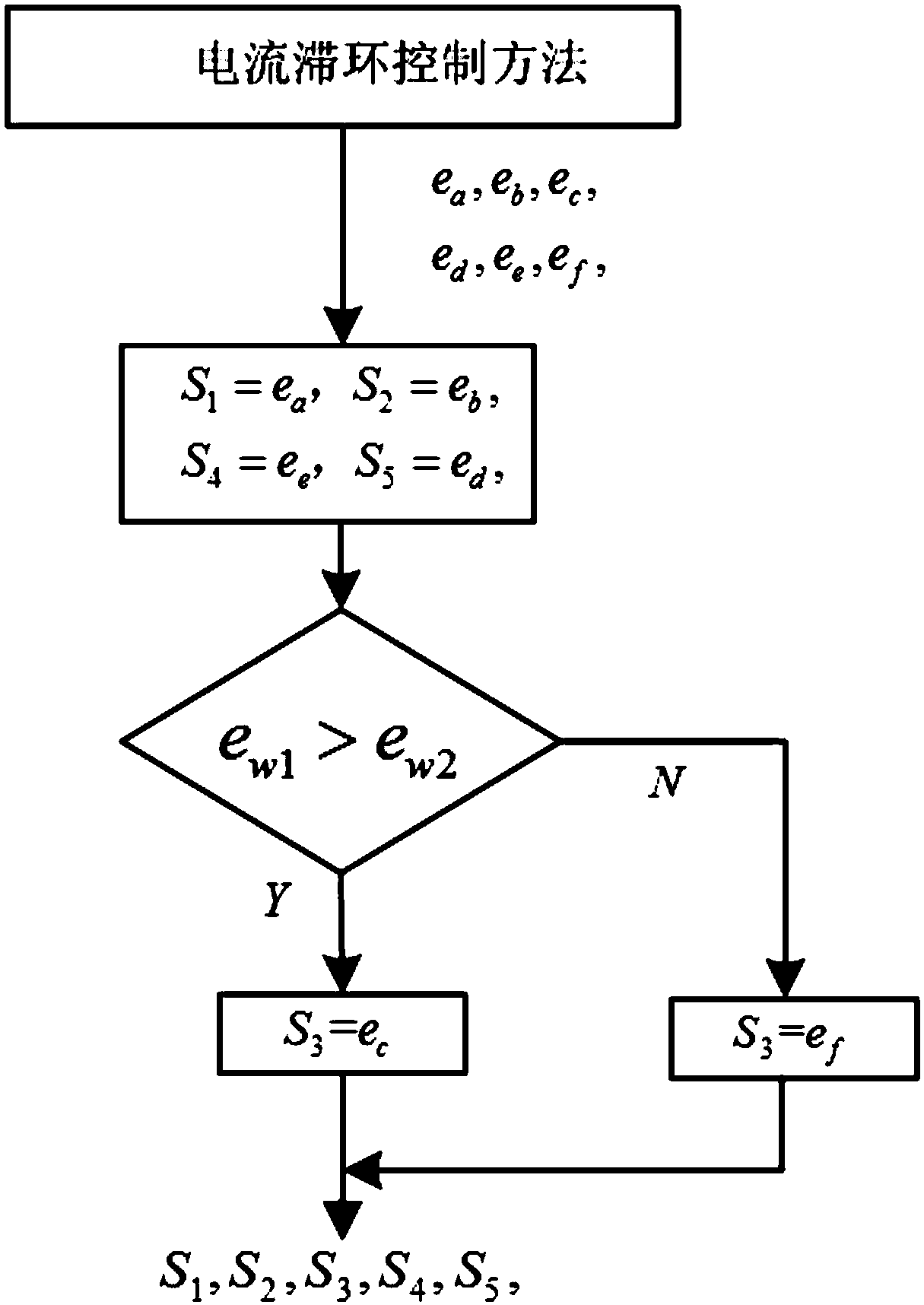

[0034] Such as figure 1 , figure 2 As shown, a dual-three-phase motor five-phase inverter includes a controller, a three-phase motor M1, a three-phase motor M2, and five inverter bridge arms connected in parallel to a DC power supply; the five inverter bridge arms are all Including two power switch tubes connected in series, one winding of the three-phase motor M1 and the three-phase motor M2 is connected between the two power switch tubes of one of the inverter bridge arms to form a common bridge arm, and the other two windings of the three-phase motor M1 The first winding and the other two windings of the three-phase motor M2 are separately connected between the two power switch tubes of the other four inverter bridge arms.

[0035] Five inverter bridge arms including inverter bridge arm L 1 , Inverter arm L 2 , Inverter arm L 3 , Inverter arm L 4 and the inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com