Tubing hanging ring detection device based on lengthened coupling

A technology for hanging rings and oil pipes, which is applied in the field of detection devices for hanging rings in oil pipes, can solve the problems of fracture, hidden dangers, complicated design and processing, etc., and achieve the effects of no omission in detection, convenient installation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the drawings and embodiments.

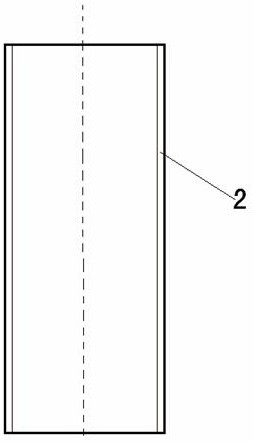

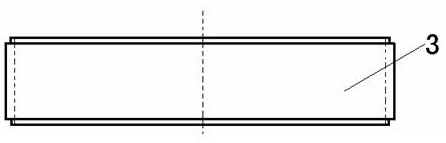

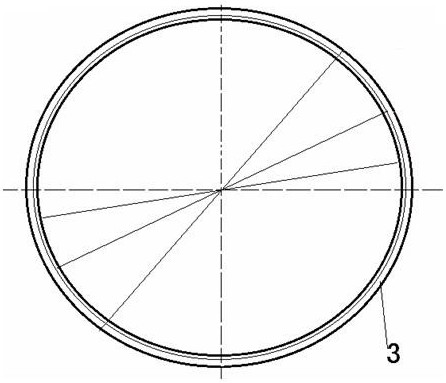

[0023] see figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, the oil pipe inner hanging ring detection device based on the extension coupling, including the oil pipe extension coupling 1, the middle part of the oil pipe extension coupling is an unthreaded pipe section 7; the unthreaded pipe section 7 An annular platform 6 is provided at the bottom of the bottom; an inner hanging ring sleeve 2 is sleeved in the unthreaded pipe section 7; at least three inner hanging rings 3 are arranged on the inner hanging ring sleeve 2; spacer rings are sleeved between the inner hanging rings 4. The outer sides of the inner hanging rings 3 at the upper and lower ends of the sleeve are respectively sleeved with an inner hanging ring cover ring 5; the inner hanging ring sleeve 2 is stuck on the ring platform 6.

[0024] see figure 1 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com