Chlorine gas magnetic levitation centrifugal compressor

A centrifugal compressor and magnetic levitation technology, which is applied in the field of gas compression, can solve the problems of high gas flow rate, large frictional resistance, and reduced work efficiency, and achieve the effects of reducing air flow pulsation, improving compression efficiency, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

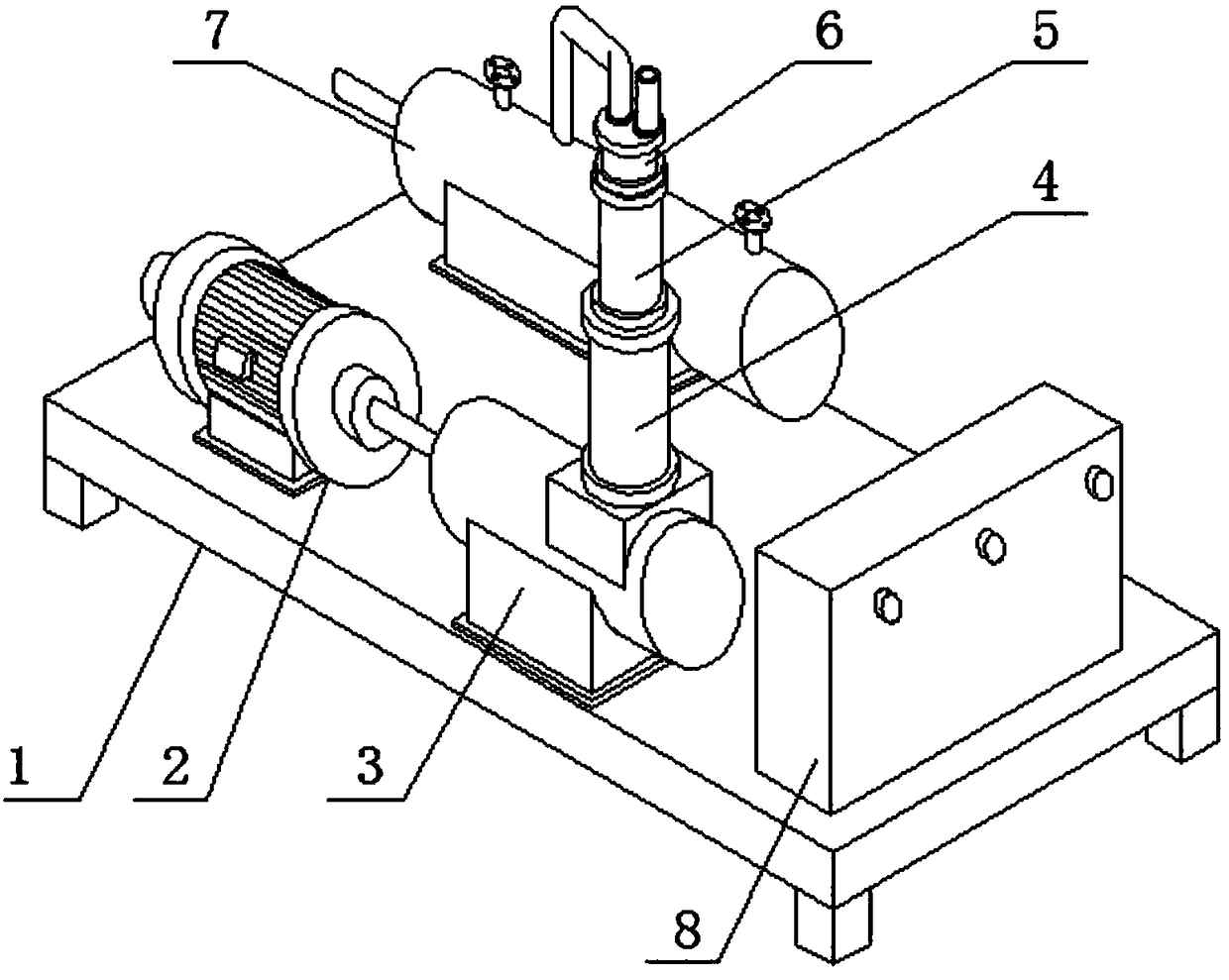

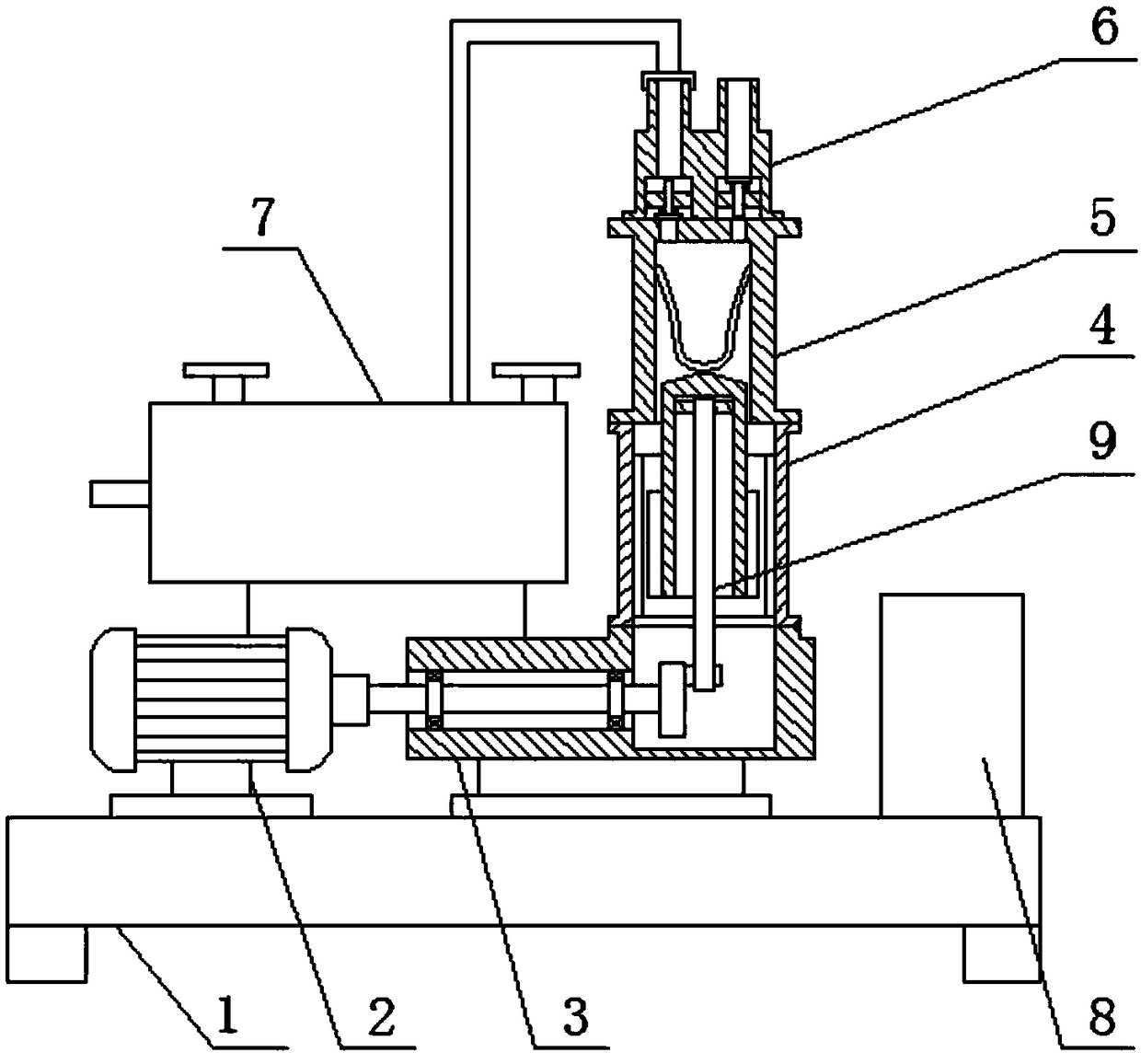

[0034] Examples, see Figure 1-8 , the present invention provides a technical solution:

[0035] A chlorine gas magnetic levitation centrifugal compressor, comprising a base 1, a motor 2, a transition mechanism 3, a magnetic levitation stator group 4, a piston cavity 5, a closing combination 6, a cooling nitrogen tank 7, a control box 8 and a magnetic levitation mover group 9, the The bottom of the base 1 is provided with legs, the motor 2 is arranged on the top of the base 1, the transition mechanism 3 is arranged on the top of the base 1 and connected with the motor 2, and the magnetic levitation stator group 4 is arranged on the top of the transition mechanism 3 At the top, the piston cavity 5 is arranged on the top of the magnetic levitation stator group 4, the closed assembly 6 is arranged on the top of the piston cavity 5, and the cooling nitrogen tank 7 is arranged on the top of the base 1 and connected with the closed assembly 6, The control box 8 is arranged on the t...

Embodiment approach

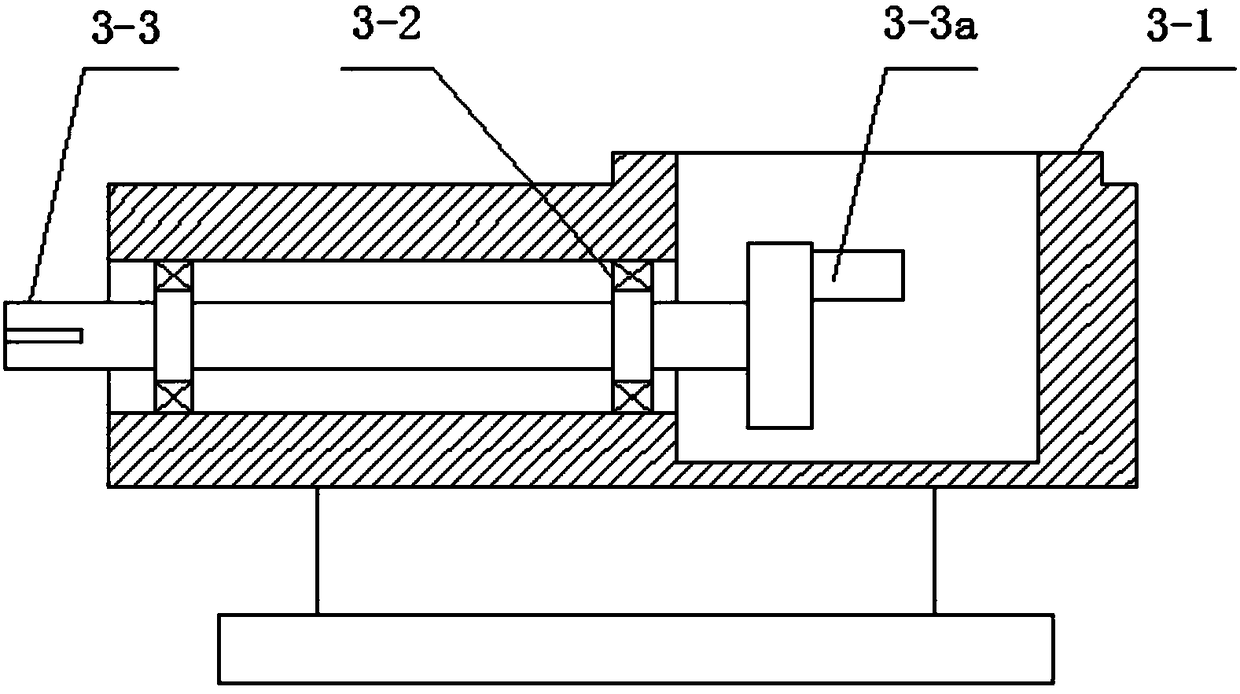

[0043] As a preferred embodiment of the present invention, the output end of the motor 2 is provided with a casing, the casing is provided with an inner keyway, one end of the transition shaft 3-3 is provided with an outer keyway, and the transition shaft 3 -3 is installed on the motor 2 through the cooperation of the key and the inner keyway and the outer keyway, and the motor 2 and the transition mechanism 3 are connected together and transmit motion through the key, and the structure is simple.

[0044] As a preferred embodiment of the present invention, the stator housing 4-1 is provided with cooling holes, the top of the piston housing 9-1 is provided with a connecting head 9-1a, and the connecting rod 9-3 is One end is provided with a connecting hole; the compressed air bag 5-2 is connected to the piston housing 9-1 through the connecting head 9-1a, and the connecting rod 9-3 is installed on the transition shaft through the cooperation of the connecting hole and the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com