Non-triggering-type electrode capable of reducing arcing energy of vacuum electric arc thruster

A non-triggering, vacuum arc technology, used in thrust reversers, machines/engines, plasma utilization, etc., can solve the problems of complex vacuum arc thruster systems, high power requirements, and complex power supply structures, and achieve increased flash The probability of arcing, the simplification of the power supply structure, the effect of high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

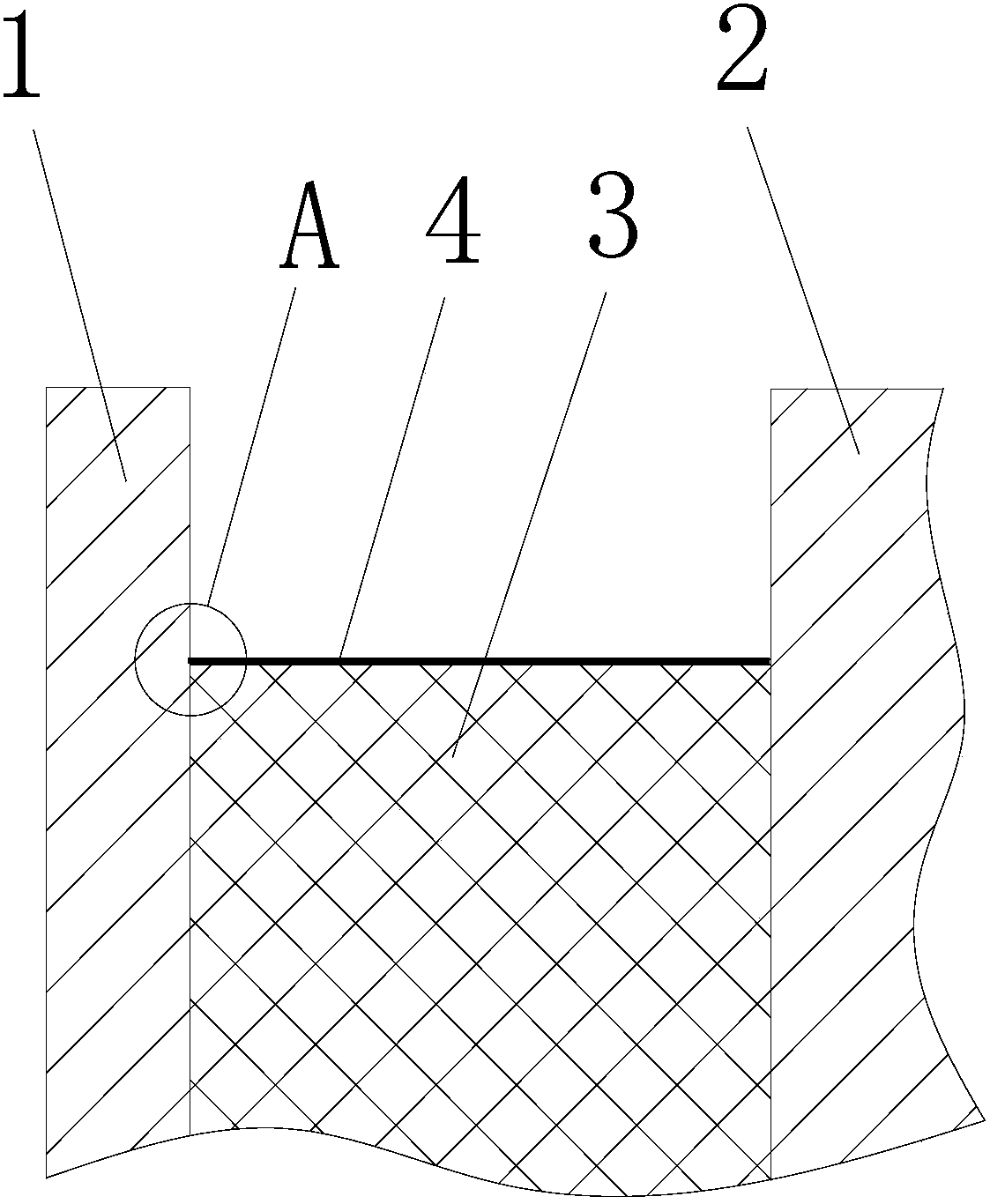

[0021] (1) The cylindrical anode, the cylindrical ceramics, and the cylindrical cathode are coaxially arranged radially from the inside to the outside, so that the distance between the cathode and the anode is 0.1 mm to 2 mm;

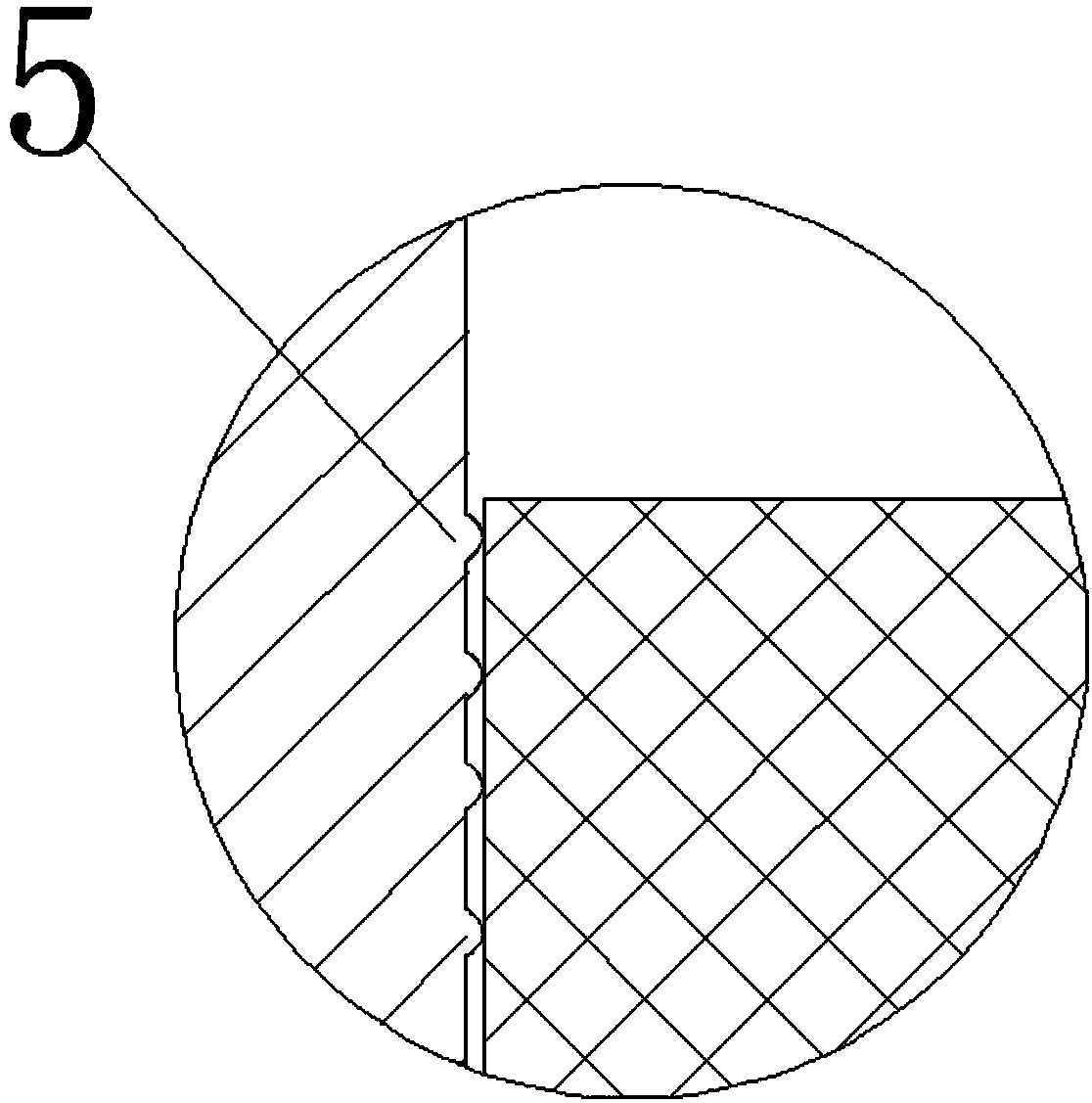

[0022] (2) Coating a layer of graphite on the upper surface of the ceramics by using the coating method of vapor phase thin film deposition, vapor deposition for 20 hours, and the thickness of the graphite layer on the ceramic surface is 100 μm;

[0023] (3) Measure the resistance between the cathode and the anode, and the resistance is 7KΩ;

[0024] (4) Load high voltage to the vacuum arc thruster, the arcing voltage of the vacuum arc thruster is 320V, and the arcing current is 60A;

[0025] (5) The size of the power supply of the vacuum arc thruster is 100mm*100mm*100mm.

Embodiment 2

[0027] (1) The cylindrical anode, the cylindrical ceramics, and the cylindrical cathode are coaxially arranged radially from the inside to the outside, so that the distance between the cathode and the anode is 0.1 mm to 2 mm;

[0028] (2) Coating a layer of graphite on the upper surface of the ceramics by using the coating method of vapor phase thin film deposition, vapor deposition for 35 hours, and the thickness of the graphite layer on the ceramic surface is 300 μm;

[0029] (3) Measure the resistance value between the cathode and the anode, and the resistance value is 2.5KΩ;

[0030] (4) Load high voltage to the vacuum arc thruster, the arcing voltage of the thruster is 300V, and the arcing current is 60A;

[0031] (5) The size of the power supply of the vacuum arc thruster is 100mm*100mm*100mm.

Embodiment 3

[0033] (1) The cylindrical anode, the cylindrical ceramics, and the cylindrical cathode are coaxially arranged radially from the inside to the outside, so that the distance between the cathode and the anode is 0.1 mm to 2 mm;

[0034] (2) Coating a layer of graphite on the upper surface of the ceramics by using the coating method of vapor phase thin film deposition, vapor deposition for 40 hours, and the thickness of the graphite layer on the ceramic surface is 500 μm;

[0035] (3) Measure the resistance value between the cathode and the anode, and the resistance value is 1KΩ;

[0036] (4) Load high voltage to the vacuum arc thruster, the arcing voltage of the thruster is 280V, and the arcing current is 60A;

[0037] (5) The size of the power supply of the vacuum arc thruster is 100mm*100mm*100mm.

[0038] Therefore, within the range of 10 μm to 800 μm, the greater the thickness of the graphite coating, the smaller the required arcing energy. Using the electrode designed in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com