Coal mine underground dust removal device and dust removal method

A technology for dust removal devices and coal mines, applied in safety devices, dust prevention, mining equipment, etc., can solve the problems of large particle size of spray dust, dust removal problems, limited working space, etc., to achieve high dust removal efficiency, easy movement, and applicability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

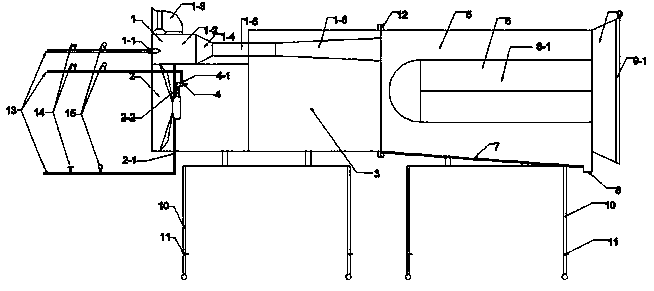

[0049] When the device is in operation, first move the dust removal device to a suitable position, connect the air-inducing part and the dust removal part through the buckle 12, adjust the height and angle of the device by adjusting the height adjustment button 11 on the mobile bracket 10, and turn the air pressure pipe The rubber hose 13 drawn from the water supply line is connected to the flow valve 14 and the pressure flow meter 15 respectively, and the end is connected with the pressure air inlet 1-1 and the air inlet 2-1 with screws. Similarly, the rubber hose 13 drawn from the water supply pipeline is connected to the flow valve 14 is connected with the pressure flow meter 15, and the end is also connected with the water inlet 4-1 of the dry mist nozzle 4 by screws;

[0050] Open the flow valve 14 on the rubber hose 13 connecting the pressure air pipeline and the water supply pipeline, the air flow enters the injection chamber 1-2 through the ejector pressure inlet 1-1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com