Light polyurethane-polyurea pouring sealant and preparation method thereof

A technology of polyurethane and potting glue, which is applied in the field of polyurethane and polyurea, which can solve the problems of increased weight, high density, and decreased energy density of battery packs, and achieves reduced permanent deformation, high compressive strength, and excellent chemical resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

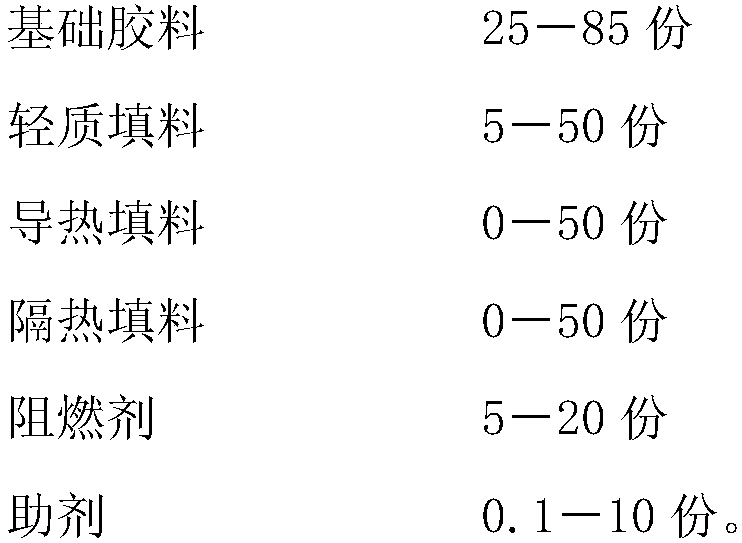

[0030] This embodiment provides a lightweight polyurethane-polyurea potting compound prepared by mixing the following components by weight:

[0031]

Embodiment 2

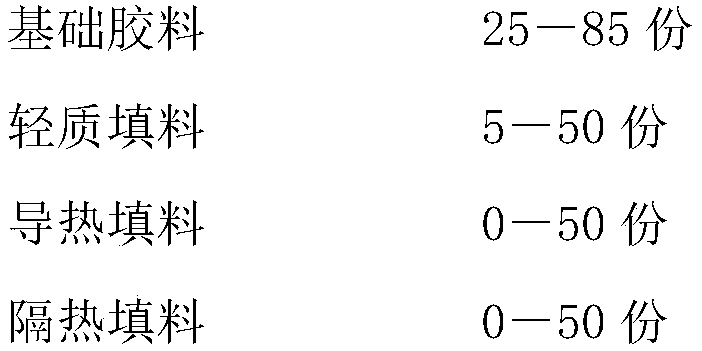

[0033] This embodiment provides a lightweight polyurethane-polyurea potting compound prepared by mixing the following components by weight:

[0034]

Embodiment 3

[0036] This embodiment provides a lightweight polyurethane-polyurea potting compound prepared by mixing the following components by weight:

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com