A kind of polypropylene composite material and preparation method thereof

A technology for composite materials and polypropylene, which is applied in the field of polypropylene composite materials and its preparation, can solve the problems of complex preparation process, long preparation cycle and difficulty in mass production, and achieve simple preparation process, suitable for large-scale mass production, The effect of enhanced frictional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

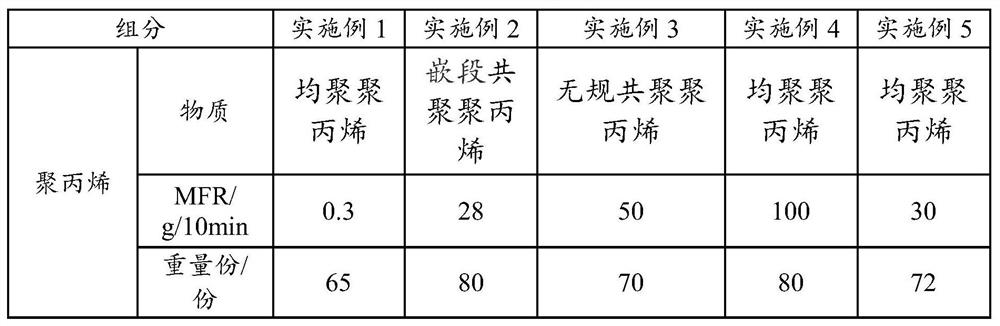

[0029] An embodiment of the polypropylene composite material of the present invention, the components of the polypropylene composite material in this embodiment are shown in Table 1.

[0030] The preparation method of polypropylene composite material described in this embodiment is:

[0031] (1) take each component by proportioning;

[0032] (2) Put tungsten disulfide nanorods, compatibilizer, polypropylene accounting for 30%-50% of the total polypropylene weight and processing aid accounting for 20%-40% of the total weight of the processing aid into the internal mixer for compaction Refining, then adopting the single-screw extruder extruding granulation that the length-to-diameter ratio of the extrusion screw is 20:1, obtains tungsten disulfide nanorod masterbatch;

[0033] (3) The remaining polypropylene, the tungsten disulfide nanorod masterbatch, toughening agent, mineral filler, coloring agent and remaining processing aids of the gained tungsten disulfide of step (2) are...

Embodiment 2~5

[0035] The components of the polypropylene composite materials described in Examples 2-5 are shown in Table 1, and the preparation methods of the polypropylene composite materials described in Examples 2-5 are the same as in Example 1.

[0036] The polypropylene composite material described in Examples 1 to 5 is injection-molded into ISO mechanical splines and long plates of 200×5×2mm by injection molding machine, and then its tensile strength, bending strength, notched impact strength, abrasion resistance and scratch resistance are measured. , surface Rockwell hardness and surface friction coefficient and other properties. The test results are shown in Table 1.

[0037] Among them, the test methods for each performance index are:

[0038] Tensile strength test standard is based on ISO 527-2, test conditions: temperature 23°C, tensile rate 50mm / min;

[0039] Bending strength test standard is based on ISO 178, test conditions: temperature 23°C, bending rate 2mm / min, span 64mm...

Embodiment 6

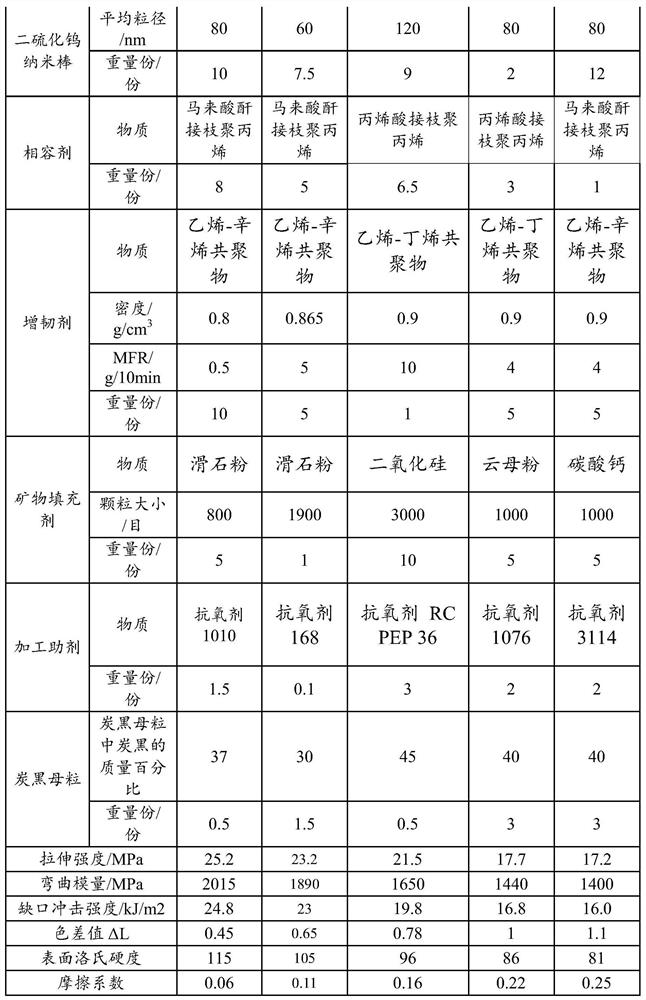

[0048] The content of tungsten disulfide nanorods in the polypropylene composite material of the present invention affects the performance of the polypropylene composite material. In order to investigate the influence of the content of tungsten disulfide nanorods on the performance of the polypropylene composite material, the applicant prepared according to the method of Example 1 The polypropylene composite materials of the test group and the control group were tested according to the performance test methods of the polypropylene composite materials described in the above-mentioned Examples 1-5, and the properties of the polypropylene composite materials of the test group and the control group in this embodiment were tested.

[0049] In this example, the components and properties of the polypropylene composite materials of the test group and the control group are shown in Table 2.

[0050] Table 2

[0051]

[0052] In the above Table 2, the polypropylene is PP EP548R, a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com